On December 2, the first set of water-cooled cyclone separator dedusting and dry quenching coke waste heat boiler integration equipment in China, which was developed and designed by Jianlong Chuanguo, was successfully put into operation. This is a new breakthrough for Jianlong Chuanguo to solve the pain point problem of the traditional dry quenching process, and an important milestone for practicing the concept of efficient and clean utilization of industrial green energy.

The traditional dry coke quenching technology commonly adopts gravity baffle wall type dust collector, which has the problems of low separation efficiency, easy collapse of baffle wall and serious wear and tear of waste heat boiler and other pain points. As early as 2011, Beijing Huatai Yongchuang and Jianlong Chuanguo jointly attempted to couple Chuanguo's patented water-cooled cyclone separator as a primary dust collector in the field of dry quenching coke system. After years of repeated trials and demonstrations, it was finally successfully implemented on specific projects.

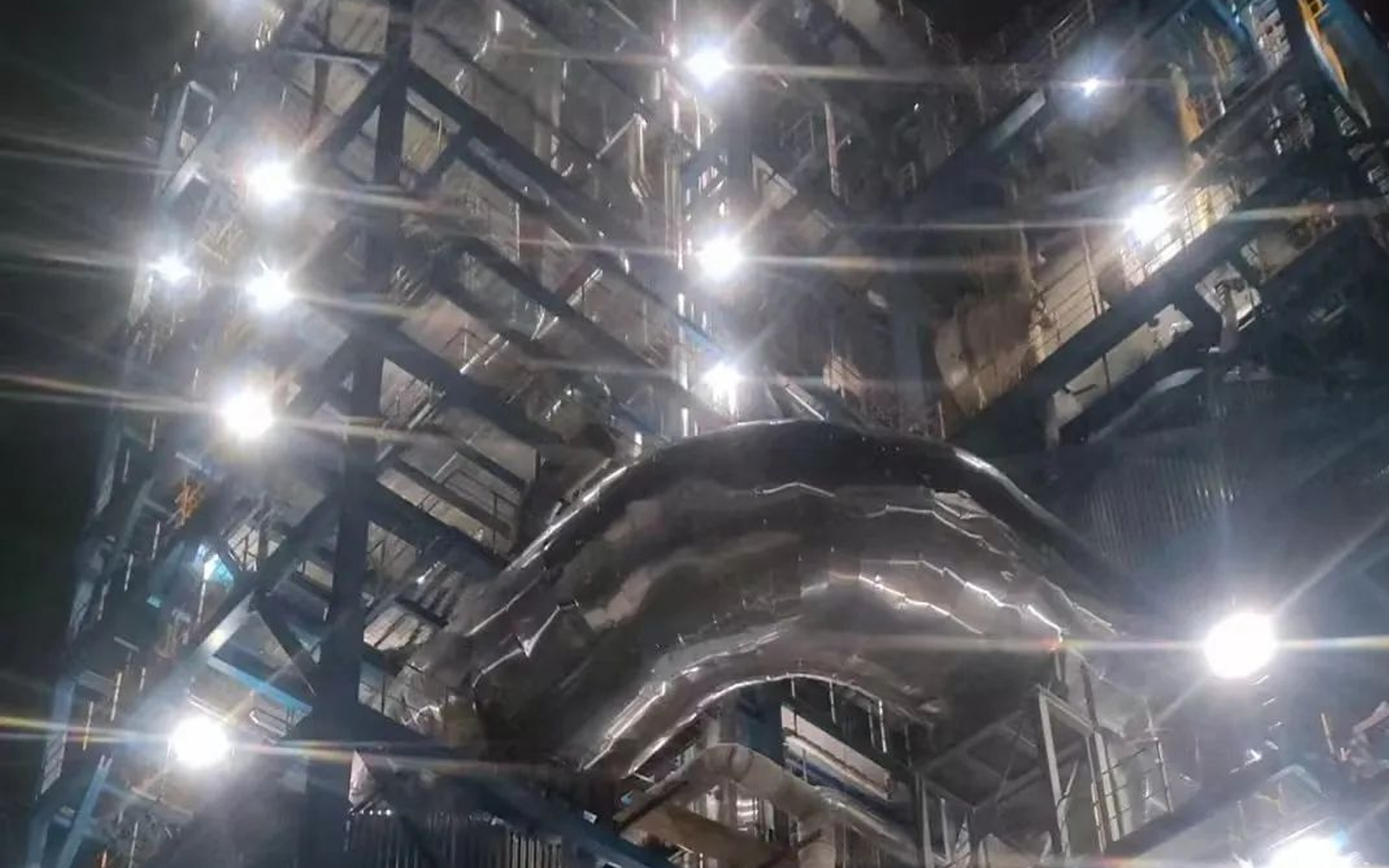

It is understood that the integrated technology of water-cooled cyclone dedusting and dry quenching coke waste heat boiler of Jianlong Chuanguo replaces the gravity baffle wall dust collector with the water-cooled cyclone separator with higher separating efficiency, which completely solves the problem that the gravity baffle wall is prone to collapsing, and the coke powder is captured before the flue gas enters into the waste heat boiler, so as to solve the problem of the serious wear and tear of the waste heat boiler from the source. In addition, the separator is cooled by saturated water, which improves the working conditions of the wear-resistant material. The actual temperature of the furnace wall material has been reduced from 920°C to about 500°C, which greatly improves the service life of the resistant material.

As the only “National Joint Engineering Research Center” for High-Efficiency and Energy-Saving Technologies for Small and Medium-sized Boilers in China, Jianlong Chuanguo has been deeply engaging in the research and development of high-efficiency and energy-saving technologies for small and medium-sized boilers in recent years, being committed to providing solutions for the field of waste heat recovery for the iron and steel, coking and chemical industries.

In the future, Jianlong Chuanguo will always adhere to the concept of efficient and clean utilization of industrial green energy, and constantly strive to achieve breakthroughs in core equipment and technology through scientific and technological innovation, contributing to solving the industry's traditional pain points.

|

|

|

|

|

| Timely Info | Independent | Platform | Multiple guarantees | Self-operated storage |

| About us | Channel | Useful tools |

|---|---|---|

| About China Steel Market | Prices | Steel weight calculation |

| Contact us | Answers | |

| Terms & Conditions | Inventory | |

| Privacy Policy | Help |

Hot search words: