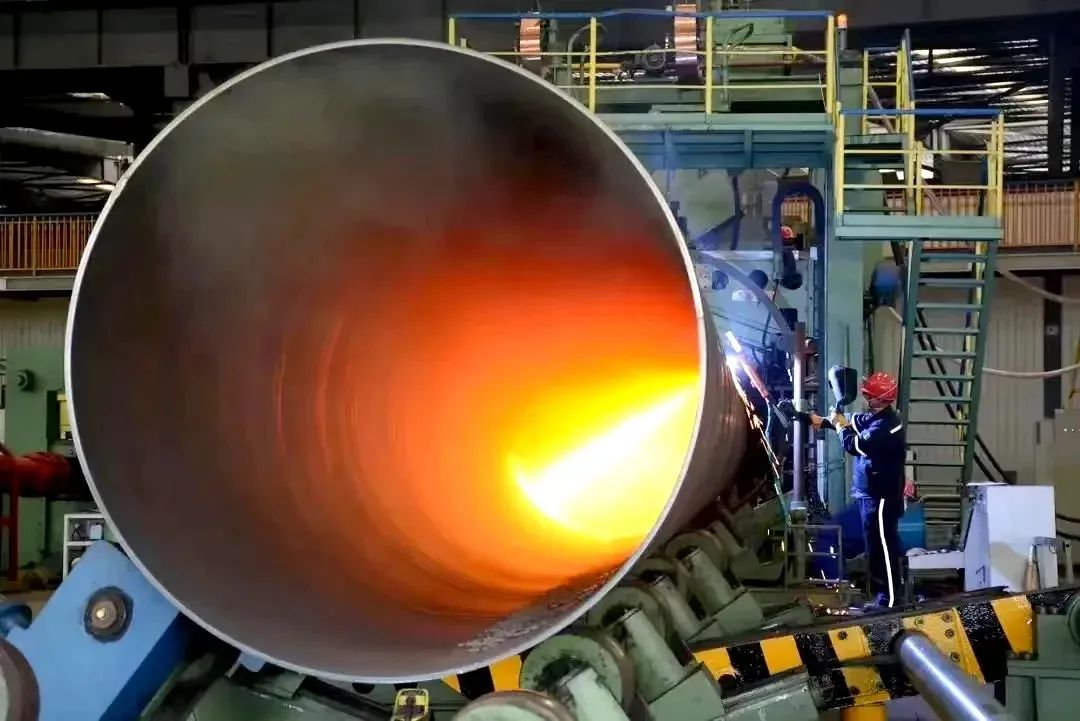

Since the beginning of this year, Baogang Co., Ltd.'s marketing center has played a leading role in sales, taking terminals and projects as the source, looking forward to the market dynamics of hydrogen pipelines and natural gas hydrogen-blended mixed transmission pipelines, and leveraging the advantages of "Production-sales-research Tripartite Linkage". It has obtained orders for the pilot demonstration project of hydrogen-blended natural gas pipelines in Yulin. At the same time, it has also completed the research and development trial production of pipeline steel required for the high-frequency straight seam welded pipes of the "West Hydrogen East Transmission" pure hydrogen transmission pipeline led by Sinopec. From hydrogen blending to pure hydrogen, Baogang pipeline steel products continue to challenge the "ceiling" in the hydrogen energy pipeline construction field.

At present, hydrogen energy is a hot topic in the energy market. In the construction of economies of scale based on hydrogen energy, efficient and safe transportation of hydrogen is a key link. Especially in the case of long distances and large demand, pipeline transportation has the advantages of large carrying capacity, high efficiency, and economic benefits, making it the most important way of energy transportation. This has also driven the transformation of the pipeline steel product market to hydrogen energy pipelines.

As the first steel enterprise in China to enter the "hydrogen energy era", Baogang Group Baogang Co., Ltd. follows the market, locks in the bottleneck in the field of hydrogen energy storage and transportation, accelerate the research and development and manufacturing of Baogang pipeline steel products and actively invests in my country's hydrogen energy pipeline construction projects.

Not long ago, the Guyang-Bayunebo hydrogen-blended gas transmission pipeline project in western Inner Mongolia started, with a total length of 125 kilometers. This is China's first high-pressure, high-grade, long-distance, large-diameter pipeline project with a hydrogen blend of more than 20%. The pipeline steel products required for its construction are all from the Baogang Group. Inner Mongolia has low hydrogen production costs and a series of green hydrogen industry development advantages. Inner Mongolia is making every effort to build a full industrial chain of green hydrogen "production, storage and use" and build a leading green hydrogen industry demonstration base in China.

|

|

|

|

|

| Timely Info | Independent | Platform | Multiple guarantees | Self-operated storage |

| About us | Channel | Useful tools |

|---|---|---|

| About China Steel Market | Prices | Steel weight calculation |

| Contact us | Answers | |

| Terms & Conditions | Inventory | |

| Privacy Policy | Help |

Hot search words: