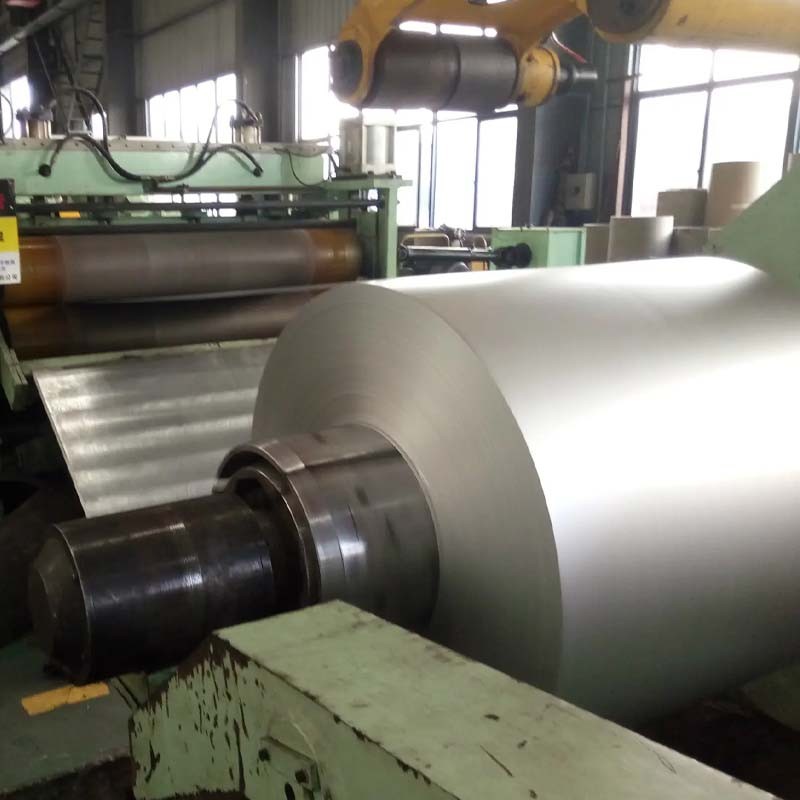

Tinned steel coil, also known as tinplate or electrolytic tinplate (ETP), is a type of coated steel product that has a thin layer of tin on its surface. The tin coating provides excellent protection against corrosion and improves the material's properties for various applications. Tinned steel coils are widely used in industries such as packaging, automotive, electronics, and construction.

The production process of tinned steel coil involves two main steps:

Electroplating:

The base steel coil, which is typically made from low-carbon steel, is thoroughly cleaned to remove any surface impurities. The cleaned steel is then passed through an electrolyte solution containing dissolved tin salts. An electric current is applied to the steel, causing tin ions from the solution to deposit onto the surface of the steel, forming a uniform and tightly bonded tin layer.

Finishing:

After the electroplating process, the tinned steel coils undergo various finishing treatments to enhance their appearance and properties. This may include oiling to prevent surface oxidation and improve workability during processing.

Advantages of tinned steel coil include:

Corrosion Resistance:

The tin coating provides excellent resistance to corrosion, making it suitable for packaging and storage of food, beverages, and other products.

Ductility:

Tinned steel is ductile and can be easily formed and shaped into various containers and components.

Solderability:

The tin coating allows for excellent solderability, making it useful for electronic components and applications that require soldering.

Aesthetics:

Tinned steel has a bright and lustrous appearance, enhancing the visual appeal of products and packaging.

Applications of tinned steel coil include:

Food and Beverage Packaging:

Tinned steel is widely used for making cans, containers, and closures for packaging food and beverages.

Electrical Components:

It is used for manufacturing electronic components, such as capacitors and connectors, due to its solderability and electrical properties.

Aerosol Cans:

Tinned steel is used for aerosol cans that contain various products, such as sprays and foams.

General Packaging:

It is also utilized for general packaging applications, including household products, paints, and chemicals.

Tinned steel coil offers a reliable and efficient solution for packaging and other applications that require corrosion resistance and excellent formability. Its widespread use in various industries is a testament to its versatility and performance.

|

|

|

|

|

| Timely Info | Independent | Platform | Multiple guarantees | Self-operated storage |

| About us | Channel | Useful tools |

|---|---|---|

| About China Steel Market | Prices | Steel weight calculation |

| Contact us | Answers | |

| Terms & Conditions | Inventory | |

| Privacy Policy | Help |

Hot search words: