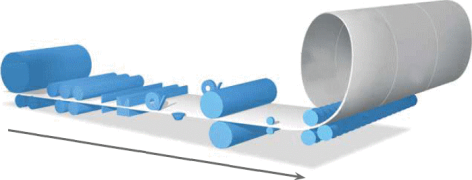

Spiral welded pipe: It is made by rolling low-carbon carbon structural steel or low alloy structural steel strip into a tube blank according to a certain helical angle (called forming angle), and then welding the pipe seam. It can be made with narrower Strip steel produces large diameter steel pipes. Its specifications are expressed by outer diameter * wall thickness. The welded pipe should ensure that the hydraulic test, the tensile strength of the weld and the cold bending performance must meet the regulations.

The Spiral Welded Pipe Manufacturing Process

1.Steel strip coil, welding wire, and flux are the raw ingredients. Before being used, it must pass stringent physical and chemical tests.

2.After the steel pipe is rolled, use automatic submerged arc welding to repair welding using single-wire or double-wire submerged arc welding.

3.The strip is leveled, cut, planed, surface cleaned, and pre-bent before forming.

4.Control the pressure of the cylinder on both sides of the conveyor with an electric contact pressure gauge to ensure that the strip is conveyed smoothly.

5.Roll molding is controlled externally or internally.

6.The amount of misalignment and the weld gap are rigorously regulated using the weld gap control device to ensure that the weld gap fulfills the welding standards and the spiral welded pipe diameter.

7.Single-wire or double-wire submerged arc welding using Lincoln welding equipment from the United States is used for internal and external welding.

8.In non-destructive testing, the final welds were evaluated by an online continuous ultrasonic automatic defect detector, ensuring 100 percent coverage of the spiral welds. If there are any problems, an automatic alarm will sound, and a spray mark will appear, allowing the production worker to alter the process parameters at any time to eliminate the errors as quickly as possible.

9.An air plasma cutting machine sliced the spiral welded pipes into individual pieces.

10 The spiral welded pipe was tested for mechanical properties, chemical composition, and bonding conditions.

11.After manual ultrasonic and X-ray inspection, the part of the weld with continuous acoustic fault detection marks, If the spiral welded pipe has a flaw, must be subjected to nondestructive examination following repair until the defect is proven to remove.

12. X-ray television or film is used to inspect the spiral welded pipe where the butt weld of strip steel and the t-joint intersecting the spiral weld are located.

13. A hydrostatic pressure test is performed on each spiral welded pipe, and the pressure is radically sealed.

Advantages of Spiral Welded Pipes

(1)Steel pipes of the same width can be utilized to make steel pipes of different diameters, especially when using narrow strip steel to make big-diameter steel pipes.

(2) The spiral weld is subjected to less stress than the straight seam, which is 75 percent to 90 percent of the straight seam welded pipe, and hence can bear immense pressure under the same pressure settings. The wall thickness can be lowered by 10% to 25% under the same pressure as a straight seam welded pipe of the same outside diameter.

The size is precise, with a general diameter tolerance of less than 0.12%, a deflection of less than 1/2000, and an elasticity of less than 1%. In most cases, the size and straightening process is straightforward.

(4) It can be created indefinitely. In theory, it can make infinitely long steel pipes with a minimal cutting head and tail cutting losses, increasing the metal utilization rate by 6% to 8%.

(5) It is more flexible in operation and easy to modify the variety than straight seam welded pipe.

(6) The equipment is lightweight and requires a minimal initial cost. It can be built into a piece of trailer-type portable equipment, and the welded pipe can be produced on-site at the pipeline installation site.

(7) Mechanization and automation are simple to implement.

Applications of Spiral Welded Pipes

Spiral Welded Pipes are commonly used to convey liquids (oil, water, etc.), gases (air), steam, etc in Chemical Industries; Petrochemical industries; Water and Wastewater engineering; Electrical power industry; Construction industry; Agricultural industry

|

|

|

|

|

| Timely Info | Independent | Platform | Multiple guarantees | Self-operated storage |

| About us | Channel | Useful tools |

|---|---|---|

| About China Steel Market | Prices | Steel weight calculation |

| Contact us | Answers | |

| Terms & Conditions | Inventory | |

| Privacy Policy | Help |

Hot search words: