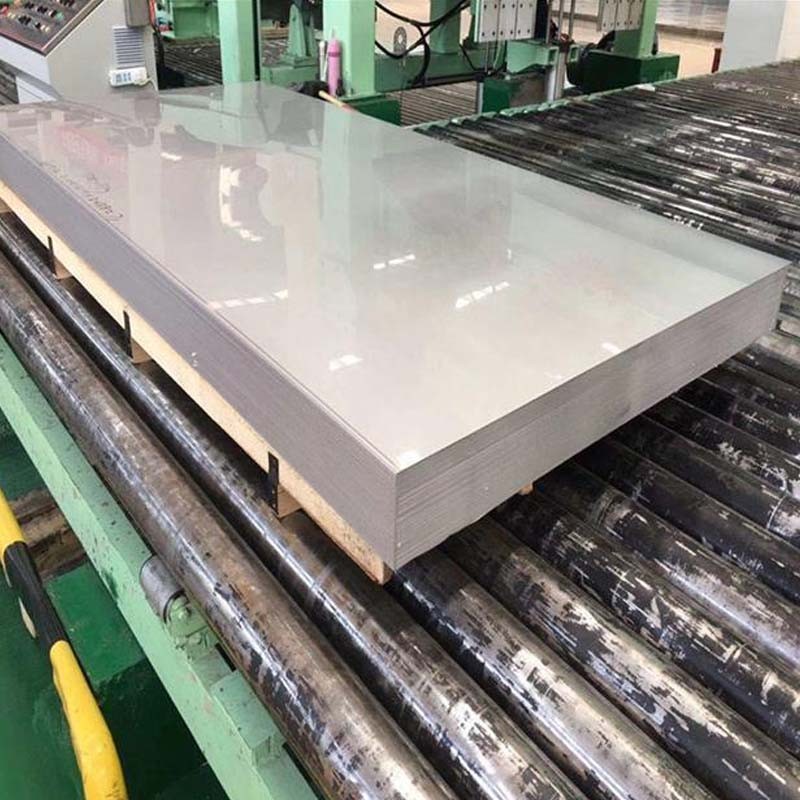

Stainless Steel Plate refers to a kind of steel plate, its thickness is generally controlled within 4-25.0mm, the thickness of 25.0-100.0mm is called thick plate, and the thickness of more than 100.0mm is called extra thick plate. The appearance color of this kind of steel plate is generally silver-white metal color as the main thickness.

Production process of stainless steel plate:

Stainless steel plate hot rolling line: billet → heating → descaling → rough rolling → finishing rolling → controlled cooling → straightening → air cooling → head cutting → edge trimming → sizing → marking → finished product

Microstructure and property control technology of stainless steel plate:

1. Intercooling technology. The most commonly used controlled rolling is two-stage rolling, that is, rolling in the recrystallized area and rolling in the non-recrystallized area. In these two stages, it is necessary to prevent partial recrystallization areas. The air cooling and waiting for temperature in the middle after rough rolling is a measure used to meet this requirement. The intermediate cooling device is to install a cooling device between the rough rolling mill and the finishing mill of the double-stand production line or before or after the single-stand rolling mill, thereby reducing the waiting time on the ramp and increasing the processing capacity of the rolling mill. After using this device, the waiting time can be reduced to 35%-80%. This device combines controlled rolling with intermediate cooling and controlled cooling after rolling. It can also be used to produce ultra-fine grain steel on the surface, or it can be called sandwich steel. This type of stainless steel has a certain thickness of ultra-fine grain layer, so Has very high crack arrest performance.

2. Pre-straightening technology. The pre-straightener can be installed between the finishing mill and the stainless steel plate cooling device. Its purpose is to reduce the warping of the head and tail of the stainless steel plate, and to correct the flatness defects in the middle section of the stainless steel plate. Straightening prevents water stains from accumulating in the stainless steel plate and optimizes cooling performance to achieve a final product with excellent plate shape.

3. Ultra-high-density laminar flow cooling process. This cooling system can not only greatly increase the cooling speed of stainless steel plates and optimize the performance of stainless steel materials, but also reduce alloy costs without increasing operating costs.

4. Wire heat treatment process. The process flow and production cycle of the direct quenching and online tempering process are relatively short, and the energy saving range is also large. The final cooling temperature of online tempering is not room temperature, but the temperature space of low-temperature phase change, so online tempering can make full use of waste heat

5. Normalized cooling technology. The normalization process can effectively enhance the structural uniformity and toughness of stainless steel plates. After normalization, the cooling rate and final cooling temperature are controlled to control the phase transformation temperature of the stainless steel plate, inhibit the growth of micro-alloying elements carbonitride, refine the grains and precipitates, enhance the strength of the stainless steel plate, and ensure toughness and plasticity. There will be basically no significant changes.

Characteristics of stainless steel plate

1. Stainless steel plate generally has very good impact resistance and vibration resistance.

2. Stainless steel plate is generally widely used in many large-scale engineering buildings, which requires it to have a very strong ability to withstand dynamic loads, and its load capacity must also be very high. Only in this way can we ensure that the engineering construction can be carried out better and better safety.

3. Stainless steel plate will also be used in some petrochemical industries. There are a lot of corrosive substances in these industries, so this kind of steel plate needs to have very good corrosion resistance.

4. Stainless steel medium and thick plates are used in different industries, and the shape and bending degree they require are different, so this kind of steel plate also has very good welding performance and cold bending performance. In addition, its plasticity and Toughness is also relatively good.

The use of stainless steel plate

1. Stainless steel plate is mainly used in construction engineering, machinery manufacturing, container manufacturing, shipbuilding and bridge construction, etc.

2. Stainless steel plate is also used in the manufacture of kitchen utensils, such as sinks, shelves and cabinets.

3. Stainless steel plates are also used in the field of transportation, such as in railway vehicles, automobile exhaust systems and bumpers, etc.

4. In terms of housing construction, stainless steel plate can also be made into guardrails, railings, protective nets, etc. for home decoration. It's more aesthetically pleasing.

Stainless steel plate is a material that is very popular in many fields now. The products manufactured by using it are of high quality in all aspects and have a relatively long service life.

|

|

|

|

|

| Timely Info | Independent | Platform | Multiple guarantees | Self-operated storage |

| About us | Channel | Useful tools |

|---|---|---|

| About China Steel Market | Prices | Steel weight calculation |

| Contact us | Answers | |

| Terms & Conditions | Inventory | |

| Privacy Policy | Help |

Hot search words: