Low alloy steel coil and plate refer to steel products that contain relatively low amounts of alloying elements, such as chromium, molybdenum, nickel, or vanadium, in comparison to high alloy steels like stainless steel or high-strength alloy steels. These alloying elements are added to improve specific properties of the steel, such as strength, hardness, toughness, and corrosion resistance.

Here's an introduction to low alloy steel coil and plate:

Ingredients:

Low alloy steel coil and plate are primarily composed of iron (Fe) as the base metal, with small additions of various alloying elements. The alloying elements are added in controlled quantities to achieve specific mechanical properties and performance characteristics.

Strength and Toughness:

Low alloy steels exhibit a balance between strength and toughness. They offer higher strength and hardness than regular carbon steels, making them suitable for structural applications where increased strength is required.

Weldability:

Low alloy steel coil and plate generally have good weldability, making them suitable for fabrication and welding processes without significant issues.

Application: Low alloy steel coil and plate find applications in a wide range of industries and structural applications. They are commonly used in construction, bridges, machinery, automotive components, pressure vessels, and offshore structures.

Grades:

There are various grades of low alloy steel coil and plate, each with its unique combination of alloying elements and mechanical properties. Some common low alloy steel grades include ASTM A572, ASTM A588, ASTM A656, EN 10025-2 S355, and JIS G3106 SM490, among others.

Corrosion Resistance:

While low alloy steels generally offer better corrosion resistance than carbon steels, they may not provide the same level of corrosion resistance as high alloy or stainless steels. For applications where corrosion resistance is critical, additional surface coatings or protection may be required.

Heat Treatment:

Low alloy steels can be subjected to heat treatment processes like normalizing, quenching, and tempering to further enhance their mechanical properties and performance.

It's important to consider the specific requirements of your application when choosing low alloy steel coil and plate. Different grades and specifications are available to meet various mechanical and environmental demands. For the most suitable low alloy steel for your needs, consult with a reputable steel supplier or manufacturer.

In China, low alloy steel coil and plate are produced and supplied according to standards set by the Chinese National Standards (GB/T - Guo Biao) or industry-specific standards. The Chinese National Standards are developed and maintained by the Standardization Administration of China (SAC) and cover various aspects of low alloy steel products, including composition, mechanical properties, and tolerances.

Some of the key GB/T standards for low alloy steel coil and plate in China include:

GB/T 3274-2017: This standard specifies hot-rolled plates and strips for carbon structural steels and high-strength low-alloy structural steels. It covers a wide range of grades and dimensions used in general structural applications.

GB/T 700-2006: This standard specifies carbon structural steels, including low alloy steel plates, used in general applications.

GB/T 1591-2018: This standard specifies the technical requirements for the classification and delivery conditions of low alloy high-strength structural steels.

GB/T 3273-2015: This standard specifies hot-rolled plates and strips for cold forming.

In the United States, low alloy steel coil and plate are produced and supplied according to various standards set by organizations like the American Society for Testing and Materials (ASTM) and the American Society of Mechanical Engineers (ASME). These standards provide guidelines for the composition, mechanical properties, and other specifications of low alloy steel products to ensure their suitability for specific applications. Some of the commonly used standards for low alloy steel coil and plate in the US include:

ASTM A572/A572M: This standard covers high-strength low-alloy (HSLA) columbium-vanadium structural steel shapes, plates, sheet piling, and bars. It includes several grades with different strength levels.

ASTM A656/A656M: This standard specifies hot-rolled structural steel, high-strength low-alloy plate with improved formability. It is used in truck frames, brackets, crane booms, rail cars, and similar applications.

ASTM A709/A709M: This standard covers carbon and high-strength low-alloy structural steel shapes, plates, and bars used for bridge construction.

ASTM A588/A588M: This standard specifies high-strength low-alloy structural steel shapes, plates, and bars used for welded, riveted, or bolted construction of bridges and buildings, and for general structural purposes.

ASTM A514/A514M: This standard specifies high-yield-strength, quenched, and tempered alloy steel plate suitable for welding.

ASTM A1011/A1011M: This standard specifies hot-rolled, high-strength, low-alloy carbon steel sheet, and strip.

ASME SA-387/SA-387M: This standard covers alloy steel plates intended primarily for welded boilers and pressure vessels designed for elevated temperature service.

In the United Kingdom, low alloy steel coil and plate are produced and supplied according to various standards, with the most common being the European Norm (EN) standards. These standards are developed and maintained by the European Committee for Standardization (CEN) and are adopted by member countries of the European Union, including the UK.

Some of the key EN standards for low alloy steel coil and plate in the UK include:

EN 10025-2: This standard specifies technical delivery conditions for non-alloy structural steels, including hot-rolled low alloy steel plates. It covers a wide range of grades and thicknesses used in general structural applications.

EN 10025-6: This standard specifies technical delivery conditions for flat products of high yield strength structural steels in the quenched and tempered condition. It includes several grades with enhanced mechanical properties suitable for various structural applications.

EN 10028-2: This standard specifies requirements for flat products made of pressure vessel steels. It includes low alloy steel plates used in the fabrication of pressure vessels for elevated-temperature applications.

EN 10113-2: This standard specifies hot-rolled products in weldable fine grain structural steels. It includes several grades of low alloy steel plates with improved formability and weldability.

EN 10149-2: This standard specifies hot-rolled flat products made of high yield strength steels for cold forming. It includes several grades suitable for cold forming processes.

EN 10210-1: This standard specifies technical delivery conditions for hot-finished hollow sections of non-alloy and fine grain structural steels.

In Japan, low alloy steel coil and plate are manufactured and supplied according to the standards set by the Japanese Industrial Standards (JIS). JIS is a national standardization body in Japan responsible for developing and maintaining standards across various industries, including the steel industry.

Some of the key JIS standards for low alloy steel coil and plate in Japan include:

JIS G3106: This standard specifies hot-rolled steels for welded structure. It includes several grades of low alloy steel plates suitable for structural applications, such as SM400, SM490, and SM520.

JIS G3101: This standard specifies hot-rolled general structural steel plates, shapes, and sections. It includes several grades with different mechanical properties for general structural purposes.

JIS G3128: This standard specifies high-strength steel plates for pressure vessels for intermediate and moderate-temperature service.

JIS G3131: This standard specifies hot-rolled mild steel plates, sheets, and strips. It covers low-carbon steel grades suitable for general applications.

JIS G3132: This standard specifies the requirements for hot-rolled carbon steel strip for pipes and tubes.

JIS G3134: This standard specifies hot-rolled high-strength steel plates with improved formability for automobile structural uses.

Allowable deviation

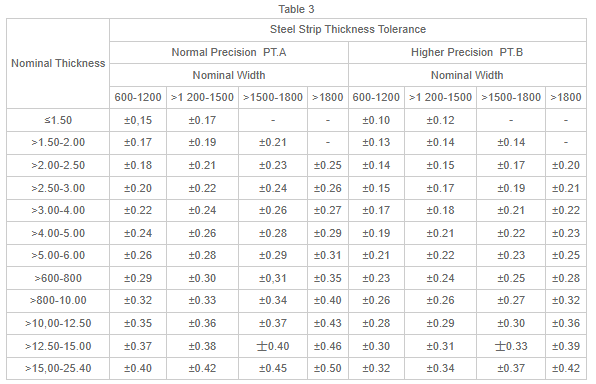

Specify the minimum yield strength R. The thickness deviation of the steel strip (including continuous rolling steel plate) less than 360 MPa shall comply with the provisions in Table 3. If the buyer requires higher thickness accuracy (PT.B) to supply, it should be specified in the contract, and if not specified, it should be supplied according to ordinary thickness accuracy (PT.A). According to the requirements of the buyer, the upper and lower deviations of the steel strip can be adjusted within the tolerance range specified in Table 3.

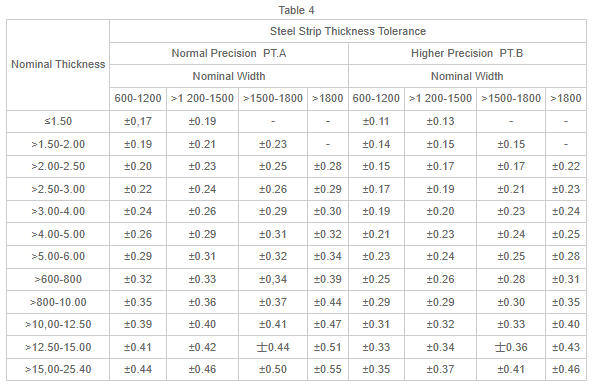

Specify the minimum yield strength R. The thickness deviation of the steel strip not less than 360 MPa (including the continuous rolling steel plate) shall comply with the provisions in Table 4. If the buyer requires higher thickness accuracy (PT.B) to supply, it should be specified in the contract, and if not specified, it should be supplied according to ordinary thickness accuracy (PT.A). According to the requirements of the buyer, the upper and lower deviations of the steel strip can be adjusted within the tolerance range specified in Table 4.

When the yield strength and the thickness tolerance are not specified in the product standard, the thickness tolerance of the steel strip (including continuous rolling steel plate) shall be negotiated by the supplier and the buyer, and shall be specified in the contract.