Hot-rolled steel plates are a type of steel product that is manufactured by passing heated steel through rolling mills at high temperatures. This process involves shaping and compressing the steel between large rollers while it is still hot, hence the name "hot-rolled." The high temperature during rolling allows the steel to be easily deformed and shaped into various forms, including sheets and plates.

Production Process:

Hot-rolled steel plates are produced from semi-finished steel products, such as slabs or billets, which are heated above their recrystallization temperature (typically around 1,100°C to 1,300°C for most steels). The hot steel is then passed through rolling mills where it is flattened and shaped to the desired thickness and dimensions.

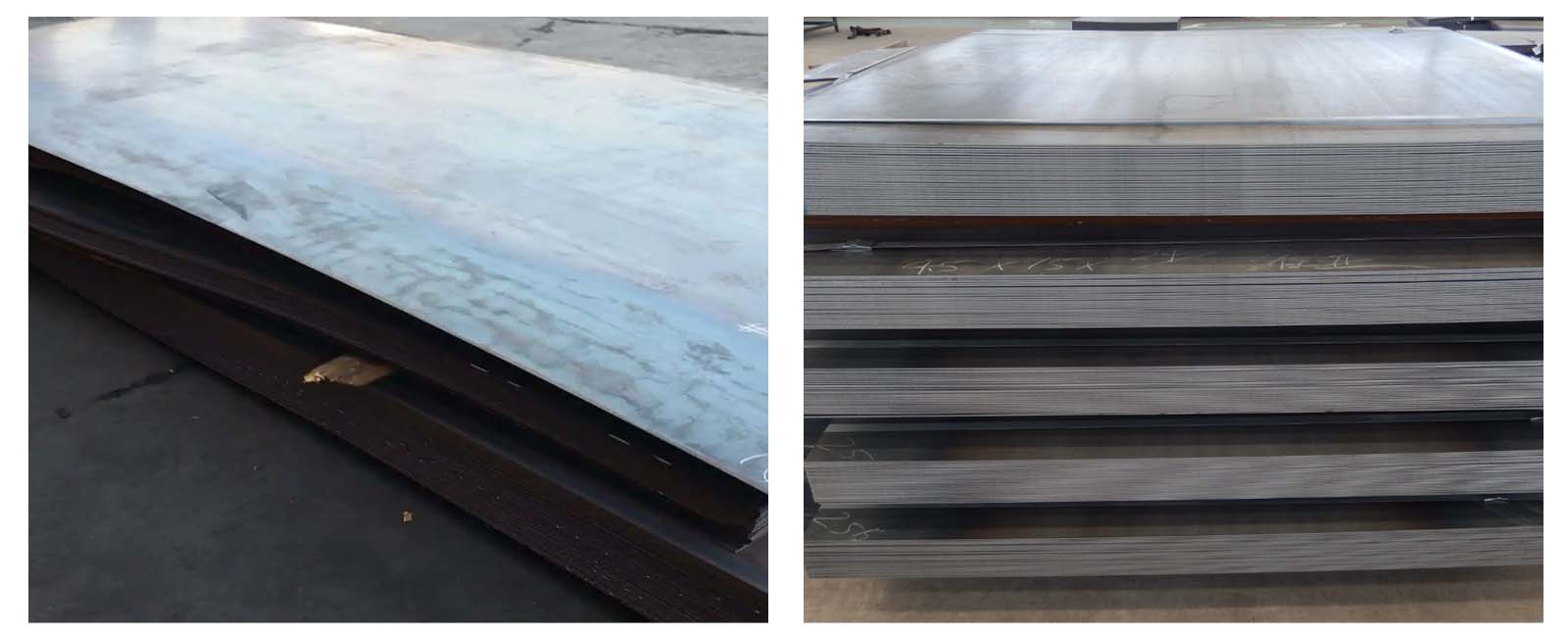

Surface Finish:

Hot-rolled steel plates have a characteristic scaled surface due to the heating and rolling process. This surface finish may not be as smooth as that of cold-rolled steel but is suitable for many industrial applications without requiring additional surface treatments.

Size and Dimensions:

Hot-rolled steel plates come in various sizes and thicknesses to meet different application requirements. Common thicknesses range from a few millimeters to several centimeters, while standard plate dimensions typically fall into the range of 1,200mm to 2,500mm in width and 2,400mm to 12,000mm in length.

Applications:

Hot-rolled steel plates find widespread use in a variety of industries and applications. They are commonly used in construction, manufacturing of heavy machinery, shipbuilding, pipelines, and general structural applications where high strength and durability are required.

Grades and Standards:

Hot-rolled steel plates are available in various grades and specifications to meet specific mechanical and chemical properties. Different international standards such as ASTM, EN, JIS, and DIN provide guidelines for the composition and mechanical properties of hot-rolled steel plates.

Further Processing:

After hot rolling, the steel plates may undergo additional treatments, such as cutting, bending, and surface finishing, to meet the exact requirements of the intended application.

It's important to note that hot-rolled steel plates may have certain drawbacks, such as dimensional tolerances and potential surface defects due to the rolling process. In some cases, cold-rolled steel plates or further processing may be required to achieve tighter tolerances and smoother surfaces.

Overall, hot-rolled steel plates are essential in the construction and manufacturing industries due to their excellent mechanical properties and widespread availability.

In China, hot-rolled steel plates are manufactured and supplied according to standards set by the Chinese National Standards or industry-specific standards. The most commonly used standard for hot-rolled steel plates in China is the GB/T 3274 standard, which covers a wide range of hot-rolled plates used in various structural applications.

Some of the key GB/T standards for hot-rolled steel plates in China include:

GB/T 3274-2017: This standard specifies hot-rolled plates and strips for carbon structural steels and high-strength low-alloy structural steels. It covers a wide range of grades and dimensions used in general structural applications.

GB/T 1591-2018: This standard specifies high-strength low-alloy structural steels. It includes several grades with different minimum yield strengths suitable for various structural applications.

GB/T 3273-2015: This standard specifies hot-rolled plates and strips for cold forming.

In the United States, the most commonly used standard for hot-rolled steel plates is the ASTM A36 standard. ASTM A36 is a widely accepted standard for carbon structural steel and covers a range of hot-rolled steel plates used in general structural applications.

ASTM A36 steel plates are available in various shapes, including plates, bars, and shapes. It sets minimum mechanical properties and chemical composition requirements for carbon steel plates used in structural applications. Some of the key mechanical properties specified by ASTM A36 include:

Other than ASTM A36, there are other ASTM standards for specific applications or higher-strength steel plates, such as ASTM A572 for high-strength, low-alloy (HSLA) steel plates, ASTM A514 for high-yield-strength, quenched, and tempered alloy steel plates, and ASTM A516 for pressure vessel plates.

In addition to ASTM standards, other organizations like ASME (American Society of Mechanical Engineers) also have standards for hot-rolled steel plates used in specific applications.

In the United Kingdom, hot-rolled steel plates are commonly manufactured and supplied according to European standards, known as EN (European Norm) standards. These standards are developed and maintained by the European Committee for Standardization (CEN) and are adopted by member countries of the European Union, including the UK.

Some of the key EN standards for hot-rolled steel plates in the UK include:

EN 10025-2: This standard specifies technical delivery conditions for non-alloy structural steels. It covers a wide range of hot-rolled plates used in general structural applications. The grades commonly used within this standard include S235, S275, S355, and others, each with different minimum yield strengths.

EN 10025-6: This standard covers high-yield-strength, quenched, and tempered structural steel plates. It includes several grades with enhanced mechanical properties, suitable for use in demanding structural applications.

EN 10028-2: This standard specifies requirements for flat products made of pressure vessel steels. It covers hot-rolled plates used in the fabrication of pressure vessels for elevated-temperature applications.

EN 10029: This standard specifies tolerances on dimensions, shape, and mass for hot-rolled steel plates with a thickness greater than or equal to 3mm.

EN 10111: This standard specifies the general requirements for hot-rolled low-carbon steel sheet and strip.

EN 10149-2: This standard specifies hot-rolled flat products made of high-yield-strength steels for cold forming. It includes several grades suitable for cold forming processes.

EN 10163: This standard specifies the delivery requirements for surface condition of hot-rolled plates and wide flats.

In Japan, hot-rolled steel plates are manufactured and supplied according to the standards set by the Japanese Industrial Standards (JIS). JIS is a national standardization body in Japan responsible for developing and maintaining standards across various industries, including the steel industry.

Some of the key JIS standards for hot-rolled steel plates in Japan include:

JIS G 3101: This standard specifies hot-rolled general structural steel plates, shapes, and sections. It covers a wide range of hot-rolled steel products used in general structural applications.

JIS G 3113: This standard specifies hot-rolled steel plates, sheets, and strips for automobile structural uses. It includes several grades suitable for automotive applications, providing specific mechanical and formability properties.

JIS G 3131: This standard specifies hot-rolled mild steel plates, sheets, and strips. It covers low-carbon steel grades suitable for general applications, such as forming and welding.

JIS G 3132: This standard specifies hot-rolled carbon steel strip for pipes and tubes. It includes several grades with specific mechanical properties for pipe and tube manufacturing.

JIS G 3134: This standard specifies hot-rolled high-strength steel plates with improved formability for automotive applications.

JIS G 4051: This standard specifies carbon steels for machine structural use, including hot-rolled steel plates.

JIS G 4053: This standard specifies low-alloyed steels for machine structural use, including hot-rolled steel plates.

Recommended nominal size

The steel plate with a thickness of less than 30 mm shall be any size in multiples of 0.5 mm; the steel plate with a thickness of not less than 30 mm shall be any size in multiples of 1 mm.

The length of the steel plate in any dimension of 50 mm or a multiple of 100 mm.

For steel plates with a thickness greater than 200mm, the thickness tolerance can also be determined through negotiation between the supplier and the purchaser, and be specified in the contract.

Allowable deviation of thickness of steel strip (including continuous rolling steel plate)

shape

The roughness of the single-rolled steel plate shall be specified respectively according to the following two types of steel:

a) Steel type L: The specified minimum yield strength value is not greater than 460 MPa, and the steel plate has not been quenched or quenched and tempered;

b) Steel type H: The specified minimum yield strength value is greater than 460 MPa, and all quenched or quenched and tempered steel plates.

Unevenness shall be determined by measuring the maximum distance between the upper surface of the plate and the ruler. If the wave spacing (the distance between the two contact points of the straightedge and the steel plate) is not greater than 1000 mm, use a 1000 mm long straightedge. For longer wave spacing use a ruler with a length of 2000 mm. For unevenness with a height not greater than 2mm, it should not be regarded as a wave.

When the wave spacing (the distance between the two contact points between the ruler and the steel plate) is between 300 mm and 1000 mm, the maximum roughness of the steel plate should also meet the following requirements:

a) Ordinary roughness accuracy (PF.A): the maximum roughness of steel type L is 1.0% of the wave pitch, and the maximum roughness of steel type H is1.5% of the wave pitch

b) Higher roughness accuracy (PF.B): the maximum roughness of steel type L is 0.5% of the wave pitch, and the maximum roughness of steel type H is 0.5% of the wave pitch.