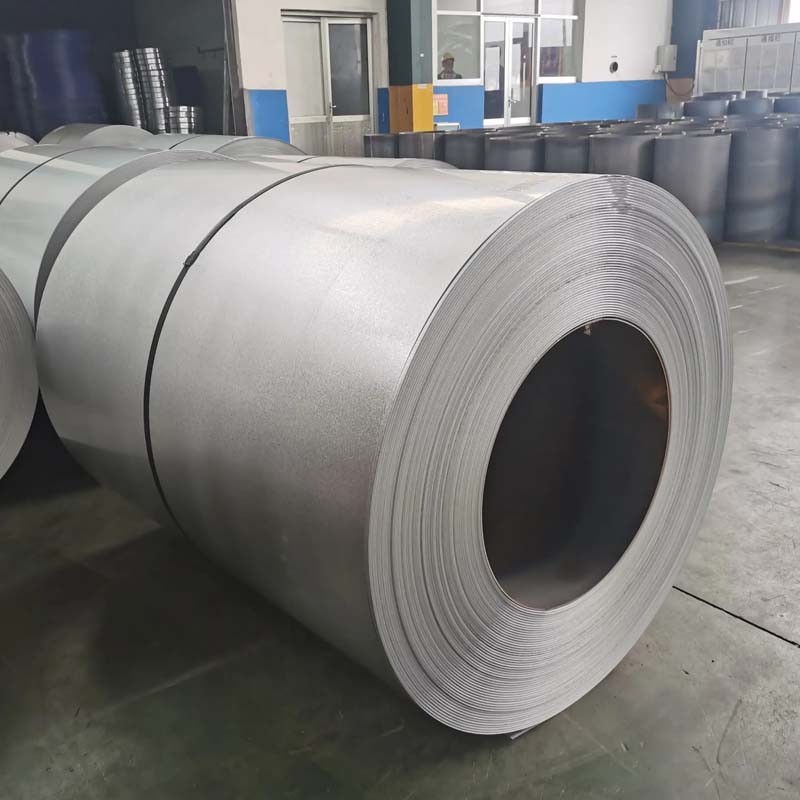

Galvanized coil is a material produced by continuous hot-dip galvanizing process with hot-rolled steel strip or cold-rolled steel strip as the substrate. Galvanized steel coil is a steel coil coated with a layer of zinc to prevent rust and corrosion. The galvanizing process involves immersing coils of steel in a bath of molten zinc, which creates a metallurgical bond between the zinc and the steel. The hot-dip galvanized sheet is supplied as a rectangular flat plate by cross-cutting; the hot-dip galvanized coil is supplied as a roll by coiling. Galvanizing is a commonly used anti-corrosion method, and has anti-rust and anti-corrosion properties,. By coating a layer of zinc on the metal surface, it can effectively prevent the metal from contacting with oxygen, moisture and other substances in the environment, thereby prolonging the use of the metal life.

Galvanized steel coil is commonly used in a variety of industrial applications, such as the construction of buildings, bridges, and other infrastructure projects, as well as in the manufacturing of automotive parts, electrical equipment, and household appliances. It is also frequently used in the production of metal roofing and siding for residential and commercial buildings.

Galvanized steel is typically made from low-carbon steel, which is a type of steel that contains less than 0.2% carbon. This type of steel is used because it is easy to work with and has good welding and forming properties.

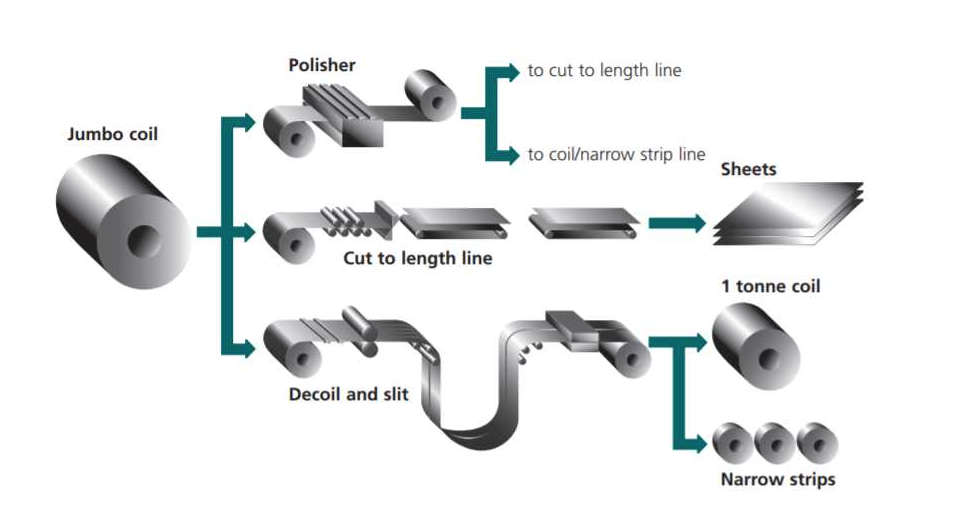

Galvanized steel sheet & coil undergoes several steps. It passes a continuing process by using an entry-end welder to connect the coil’s end to the next coil. Dirt, oils, and surface contaminants on the sheet surface are eliminated in an alkaline cleaning section.

The steel passes through a heating process in an annealing furnace at the highest temperatures to apply the desired mechanical properties, such as formability and strength. The steel sheet undergoes a molten zinc bath at a certain coating level, depending on the application.

An application of gas knives takes place to clean up excess metal coating and reach the desired coating weight. The steel sheet goes to a cooling section to cool off and allow the coating to solidify after being removed from the bath. It passes through a temper mill to obtain the steel’s desired finish on its surface before flattening it using a tension leveler.

After meeting the end-user requirements, the steel sheet passes through a treatment section to protect it from storage stains on its coating surface. A forming oil is applied in the oiling section to prevent the sheet from rusting before it goes to a recoiler for rewinding.

Galvanized steel sheet & coil has a wide range of applications, including construction, automotive, home appliances, packaging and other industries, and has its own application scenarios and advantages in different industries.

First, the nature of galvanized steel sheet & coil and manufacturing process

Galvanized coil refers to the steel surface coated with zinc sheet, the production process mainly includes: pickling, hot dip galvanizing, cold rolling and coating processes. Zinc has good anti-corrosion properties and cost advantages, and galvanized coil is easy to process, molding and welding and other characteristics, so it is widely used in various industries.

Second, the application of the construction industry

In the construction industry, galvanized coil is commonly used in the manufacture of building materials such as roofs, walls, pipes, steel structures, beams and columns. Steel structure galvanized coil has the advantages of light weight, high strength, fire prevention, anti-corrosion, etc. It is widely used in the construction of stadiums, conference centers, commercial centers and other buildings.

Third, the application of the automobile industry

Galvanized coil in the automotive industry is used as a car shell, doors, chassis, energy-saving panels and other parts of the material. Due to its advantages of high strength, high toughness and corrosion resistance, it can improve the safety and durability of automobiles and is environmentally friendly.

Fourth, the application of home appliance industry

In the home appliance industry, galvanized coil is used as a manufacturing material for refrigerators, air conditioners, washing machines, water heaters and other home appliances. Galvanized coil can meet the appearance of home appliances, strength, corrosion resistance and other requirements, and can reduce production costs and improve product competitiveness.

Fifth, the application of packaging industry

Galvanized coil is also widely used in the packaging industry, such as the manufacture of food cans, cosmetic cans, paint cans and so on. Galvanized coil has good corrosion resistance and sealing, can ensure the quality and safety of the packaging, while improving production efficiency.

In summary, with the continuous development of industrial technology, the application prospect of galvanized coil will be further expanded.

Galvanized steel sheet & coil is to prevent the outside of the steel plate to encounter corrosion, extend its application life, in the outside of the steel plate coated with a layer of metallic zinc, this zinc-coated thin steel plate is called galvanized coil.

|

|

|

|

|

| Timely Info | Independent | Platform | Multiple guarantees | Self-operated storage |

| About us | Channel | Useful tools |

|---|---|---|

| About China Steel Market | Prices | Steel weight calculation |

| Contact us | Answers | |

| Terms & Conditions | Inventory | |

| Privacy Policy | Help |

Hot search words: