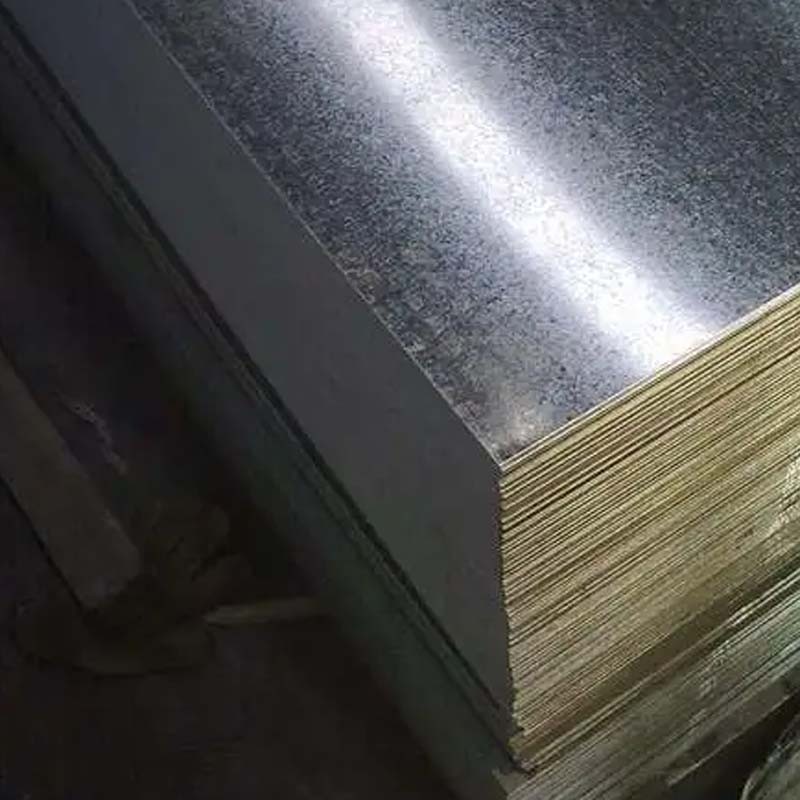

Electro Galvanized Steel Sheet & Coil is a type of coated steel product that undergoes an electroplating process to apply a thin layer of zinc onto the surface of the steel substrate. This process is different from the hot-dip galvanizing method used for regular galvanized steel.

The Electro Galvanizing Process:

Cleaning:

The steel sheet is thoroughly cleaned to remove any surface impurities, oils, and residues that may hinder the adhesion of the zinc coating.

Electroplating:

The cleaned steel is immersed in an electrolyte solution containing dissolved zinc salts. An electric current is passed through the bath, causing the zinc ions in the solution to deposit on the steel surface, creating a uniform and adherent zinc coating.

Post-treatment:

After electroplating, the coated steel may undergo further treatments such as passivation or chromating to improve its corrosion resistance and appearance.

Advantages of Electro Galvanized Steel Sheet & Coil:

Corrosion Resistance:

The zinc coating provides excellent corrosion protection to the underlying steel, making it suitable for indoor and non-exposure applications where moderate corrosion resistance is required.

Aesthetics:

Electro galvanized steel has a smooth, shiny, and uniform appearance, making it more aesthetically pleasing than regular galvanized steel.

Formability:

Electro galvanized steel retains good formability and can be fabricated and shaped into various products and components.

Cost-Effective:

Electro galvanized steel is typically more affordable than hot-dip galvanized steel, making it a cost-effective option for certain applications.

Paint Adhesion:

The smooth and clean surface of electro galvanized steel allows for better paint adhesion, making it easier to apply additional coatings if needed.

Applications of Electro Galvanized Steel Sheet & Coil:

Electro galvanized steel finds applications in various industries, including:

Automotive:

It is used in automotive parts such as body panels, fenders, and hoods.

Construction:

For interior components, HVAC ducting, and non-exposed parts in buildings.

Electrical Appliances:

For components in refrigerators, washing machines, and ovens.

Furniture: In the manufacturing of metal furniture.

It's important to note that while electro galvanized steel provides good corrosion resistance for indoor and non-exposure applications, it may not be as suitable for harsh outdoor environments compared to hot-dip galvanized steel or other specialized coatings. The choice of the appropriate type of coated steel depends on the specific requirements and the intended application.

|

|

|

|

|

| Timely Info | Independent | Platform | Multiple guarantees | Self-operated storage |

| About us | Channel | Useful tools |

|---|---|---|

| About China Steel Market | Prices | Steel Weight Calculation |

| Contact Us | Answers | Why Choose Us |

| Terms & Conditions | Inventory | |

| Privacy Policy | Help |

Hot search words: