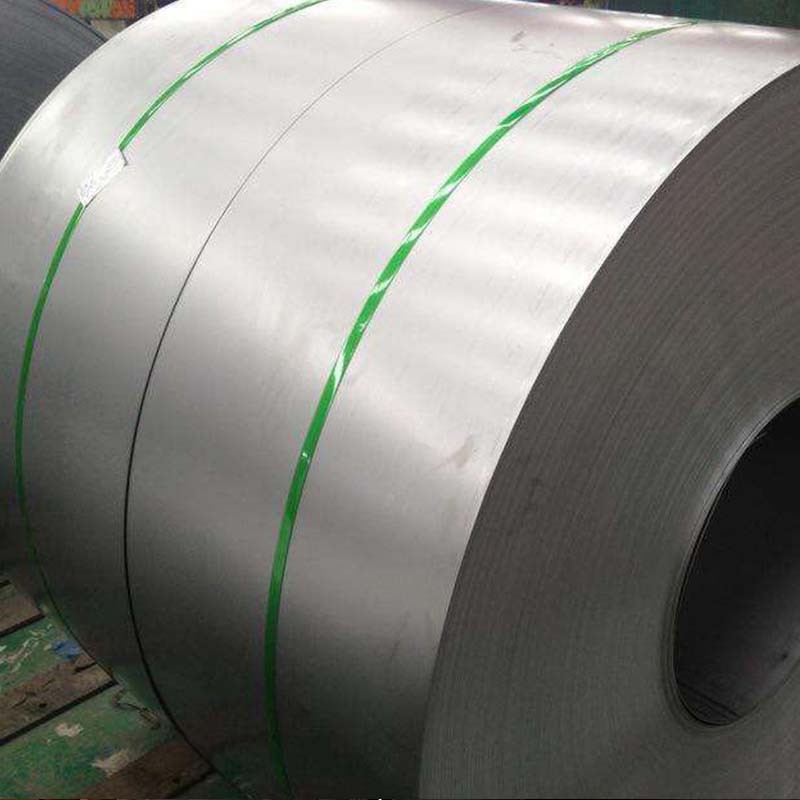

Cold rolled coil is a steel strip that is rolled directly into a certain thickness with rollers at normal temperature and wound into a complete coil with a winder. Cold rolled coils have a bright surface with a high finish, but produce more internal stresses and are often annealed after cold rolling.

Cold rolled coils are characterized by their very high strength. As a result of the cold rolling process, the grain size of the steel is refined, thus increasing the strength and hardness of the steel. Secondly, cold rolled steel coils also have excellent toughness. Cold rolling process can improve the organizational structure of steel coils, thereby improving its toughness, making it more suitable for a variety of complex processing and forming process. In addition, cold rolled coils also have a better surface finish and dimensional accuracy. Compared with hot rolled coils, the surface of cold rolled coils is smoother, without obvious bumps and oxidized layer. At the same time, the dimensional accuracy of cold rolled coils is higher, which can meet more precise requirements of application scenarios. Cold rolled coil production process, because the heating is not carried out, so there is no hot rolled often appear pitting and iron oxide and other defects, good surface quality, high finish, and cold rolled products, high dimensional accuracy, product performance and organization can meet some special requirements for use.

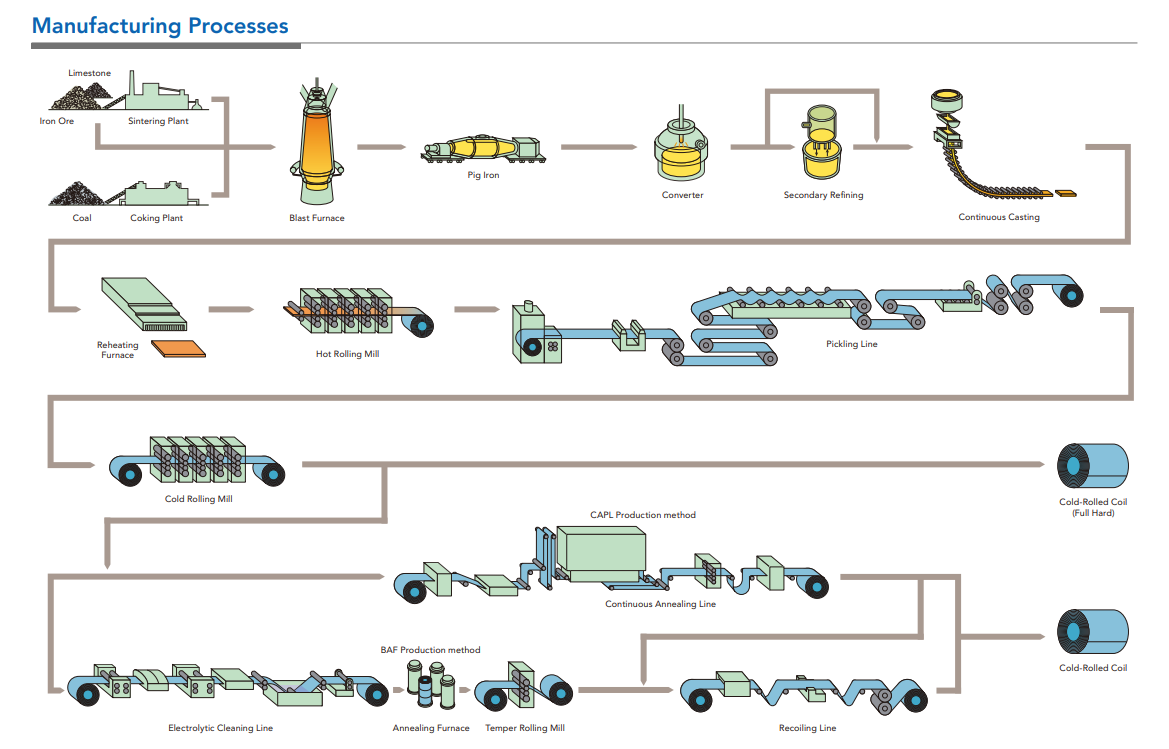

The manufacturing process of cold rolled coils usually includes the following steps:

1. Hot Rolling: First, the original steel is subjected to a hot rolling process at high temperatures to heat it to a higher temperature, and then it is pressed into the required thickness and width by a roll mill to form hot rolled steel coils.

2. Pickling: Hot rolled coils are pickled to remove surface oxidized skin and contaminants to ensure better surface quality after cold rolling.

3. Cold Rolling: Hot rolled steel coils are re-rolled at room temperature in a cold rolling mill. The thickness of the steel in this process will become more uniform, while the surface will become smoother.

4. Annealing: Cold rolled coils may need to be annealed to remove internal stresses and improve the ductility and workability of the steel.

To summarize, cold rolled steel coil, as a metal material treated by a special process, has many unique characteristics. Its high strength, good toughness and excellent surface quality make it widely used in industries such as automotive, construction and home appliances. With the advancement of technology and growing demand, the development prospect of cold rolled steel coils will be even broader. Whether in the lightweight design of new energy vehicles, the structural stability of high-rise buildings, or the environmental performance of home appliances, cold rolled steel coils will play an important role in contributing to the development of different industries.

|

|

|

|

|

| Timely Info | Independent | Platform | Multiple guarantees | Self-operated storage |

| About us | Channel | Useful tools |

|---|---|---|

| About China Steel Market | Prices | Steel Weight Calculation |

| Contact Us | Answers | Why Choose Us |

| Terms & Conditions | Inventory | |

| Privacy Policy | Help |

Hot search words: