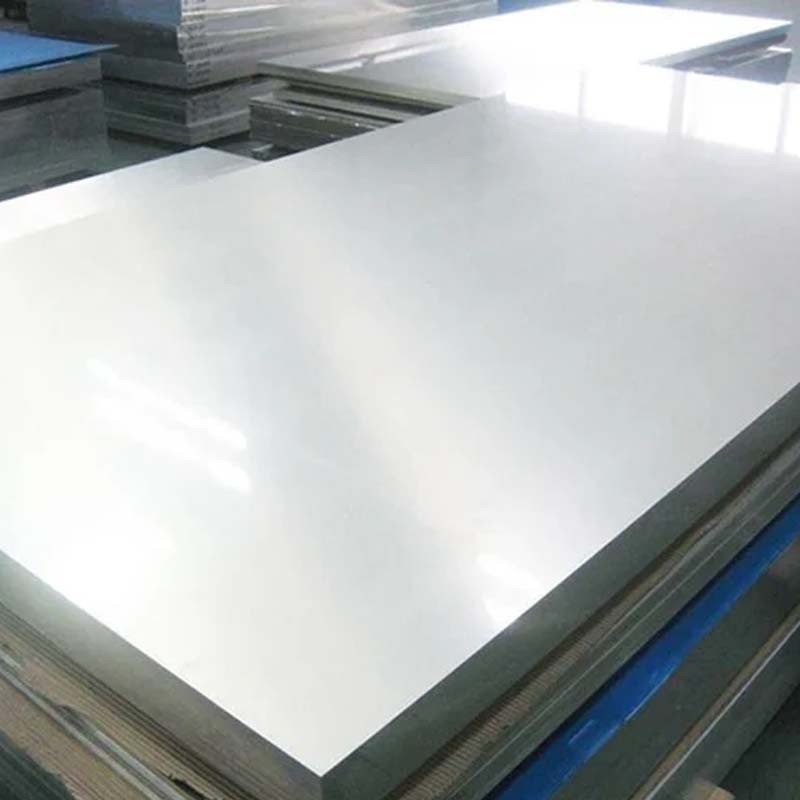

Cold Rolled Stainless Steel Sheet refers to the stainless steel plate produced by cold rolling. Cold rolling is to further thin the hot-rolled stainless steel plate to the target thickness at room temperature. It is obtained by calendering hot-rolled stainless steel sheets at room temperature, and has a smoother surface, higher hardness, and stronger corrosion resistance.

Production process

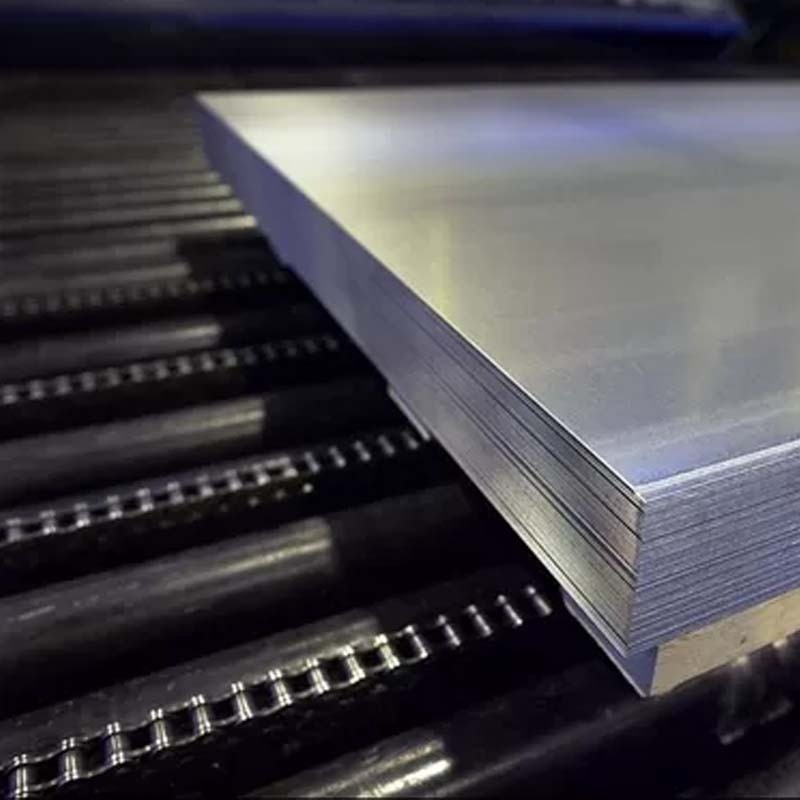

First, iron ore is smelted into billets, which are then processed into hot-rolled plates. Next, the hot-rolled sheet is pickled to remove surface oxides and rust, and then rolled to become a cold-rolled sheet. Cold-rolled sheets have to go through multiple processes such as quenching and annealing before they can become high-quality stainless steel sheets.

Cold rolled stainless steel sheet has the following main features:

1. Its surface has high smoothness. During the cold rolling process, the steel plate has been rolled, stretched and trimmed for many times, making the surface smoother and more delicate, less prone to unevenness and wrinkles, and showing a higher finish. This smooth surface is not only beautiful, but also easy to clean and maintain, meeting the hygienic requirements of many special industries.

2. The hardness of cold rolled stainless steel sheet is higher. During the cold rolling process, due to the cold working of the material at room temperature, the grains are processed and refined, which greatly increases the hardness of the material. Compared with hot-rolled stainless steel, cold-rolled stainless steel is more resistant to wear and scratches, and has better resistance to overload. Therefore, cold-rolled stainless steel sheets are often widely used in machinery manufacturing, automobile industry and other fields to manufacture high-hardness and high-strength parts.

3. Cold rolled stainless steel sheet has better corrosion resistance. Stainless steel itself has good corrosion resistance, and the cold-rolled stainless steel plate has stronger corrosion resistance due to the finer grains, denser grain boundaries, and more orderly crystal arrangements. The cold rolled stainless steel sheet can effectively resist the corrosion of external oxidation, acid-base, salt spray and other corrosive substances, thus ensuring the service life and quality of the product.

4. The processing performance of cold rolled stainless steel sheet is better. Due to the higher hardness of cold rolled stainless steel sheet, more types and more complex processing procedures can be performed, such as bending, cutting, punching, etc., which greatly improves the processing flexibility and diversity of products and meets the needs of different industries for materials various needs of processing performance.

Application of cold rolled stainless steel sheet:

1. In terms of architectural decoration: roofs, cladding and structural components

2. In the automotive industry: exhaust systems, grilles and other exterior parts

3. In terms of electrical appliances: dishwashers, refrigerators and other kitchen equipment

4. In food processing: processing and storage tanks, conveying systems and other equipment

5. In the medical field: surgical instruments, medical equipment and hospital furniture

6. In nautical aspects: marine accessories, propellers and other parts that require corrosion resistance

Cold rolled stainless steel sheet has become an indispensable material in many industries due to its high surface smoothness, high hardness, good corrosion resistance and strong processability.

Cold rolled stainless steel sheet is a raw material commonly used in the manufacture of stainless steel products, and its quality directly affects the quality and performance of the product. In order to ensure the quality of stainless steel cold-rolled steel sheets, various countries have formulated corresponding standards to ensure that they meet the specified requirements for chemical composition, mechanical properties, and surface quality.

Chinese Standard:

GB/T 3280-2015 "Stainless Steel Cold-Rolled Steel Plate and Strip" is a standard for stainless steel cold-rolled steel plate formulated by China, which is applicable to the production and use of stainless steel products.

American standard:

ASTM A240/A240M-20a is a standard formulated by the American Society for Testing and Materials (ASTM). It is one of the internationally recognized standards for stainless steel cold-rolled steel sheets and is suitable for the production and use of chromium-nickel stainless steel.

Japanese standard:

JIS G 4305:2020 is a standard formulated by the Japanese Industrial Standardization International Organization (ISO). The standard is characterized by a wide range of application and can meet the production and product use requirements of most stainless steel cold-rolled steel sheets.

The formulation and implementation of Cold rolled stainless steel sheet standards are crucial to ensuring the quality and performance of stainless steel products. The standards of different countries and regions are different, and it is necessary to select the appropriate standard for production and use according to the specific situation.

Some commonly used sizes of cold rolled stainless steel sheet

Thickness: 0.3-6.0mm

Standard width: 1000; 1250; 1500; 2000mm;

Length: 2000 to 12,500 mm;

In the process of production and processing, there may be some errors in cold rolled stainless steel sheet flat plates. These errors include thickness errors, width errors, length errors, etc., and these errors need to meet certain standards.

Thickness deviation is ±0.05mm

The allowable deviation of length is +5mm

Width allowable deviation +4.0mm