Cold-rolled ribbed steel bars, also known as cold-rolled deformed steel bars, are a type of steel reinforcement used in construction and concrete reinforcement applications. They are produced through a cold-rolling process that involves shaping the steel bars while they are at room temperature.

Features of cold rolled ribbed steel bars:

There are ribs or deformations along the bar surface. These ribs provide enhanced bonding with concrete, allowing for improved load transfer and resistance to slippage. The deformations on the surface of the bars increase the mechanical interlocking between the steel and concrete, resulting in greater structural stability and strength.

Process of cold rolling ribbed steel bar:

These steel bars are typically made from low carbon steel and undergo a series of processes, including cleaning, pickling, cold rolling, and ribbing. The cold-rolling process imparts the desired ribbed pattern onto the surface of the bars. The ribs can be either transverse or helical in shape, providing different degrees of bonding with concrete.

Application of cold rolled ribbed steel bar:

Cold-rolled ribbed steel bars are widely used in various concrete structures, such as bridges, buildings, highways, and tunnels. They offer advantages such as improved tensile strength, ductility, and bond strength with concrete. The ribbed pattern enhances the grip between the steel bars and the surrounding concrete, resulting in better load distribution and structural integrity.

These steel bars are available in different diameters and lengths to suit specific construction requirements. They are commonly specified in construction projects where superior concrete reinforcement is needed to withstand heavy loads, seismic forces, and other external factors.

Overall, cold-rolled ribbed steel bars are an essential component in reinforced concrete structures, providing strength, durability, and enhanced structural performance.

Cold-rolled ribbed steel bars adhere to various standards that ensure their quality and suitability for construction purposes. Here is an introduction to the standards commonly associated with cold-rolled ribbed steel bars:

GB Standard:

In China, the national standard for cold-rolled ribbed steel bars is GB/T 1499.2-2018.

This standard specifies the technical requirements, dimensions, tolerances, and testing methods for cold-rolled ribbed steel bars used in reinforced concrete structures.

ASTM Standard:

The American Society for Testing and Materials (ASTM) has established standards for cold-rolled ribbed steel bars.

ASTM A615/A615M is the standard specification for deformed and plain carbon-steel bars for concrete reinforcement.

ASTM A706/A706M is another standard that covers low-alloy steel bars for concrete reinforcement.

BS Standard:

The British Standards Institution (BSI) has issued standards for cold-rolled ribbed steel bars.

BS 4449:2005 is the specification for carbon steel bars for the reinforcement of concrete. It covers ribbed steel bars with various strength grades and dimensions.

JIS Standard:

The Japanese Industrial Standards (JIS) include standards for cold-rolled ribbed steel bars.

JIS G3112 is the standard specification for steel bars for concrete reinforcement, covering ribbed steel bars with specific mechanical properties and dimensions.

DIN Standard:

The Deutsches Institut für Normung (DIN) has established standards for cold-rolled ribbed steel bars.

DIN 488 is the standard specification for reinforcing steel, providing requirements for hot-rolled and cold-rolled ribbed steel bars used in concrete structures.

These are some of the commonly referenced standards for cold-rolled ribbed steel bars. Each standard outlines specific requirements related to material composition, mechanical properties, dimensions, surface characteristics, and testing methods. Adhering to these standards ensures the quality and reliability of cold-rolled ribbed steel bars for construction applications.

Currently, in the Chinese steel market, the implementation standard for cold rolled ribbed steel bars is GB/T 13788-2017. According to the standard document, cold-rolled ribbed steel bars are divided into six grades, CRB550, CRB650, CRB800, CRB600H, CRB680H, and CRB800H. Among them, CRB550 and CRB600H are ordinary reinforced concrete reinforcement bars, CRB650, CRB800, and CRB800H are prestressed concrete reinforcement bars, and CRB680H is applicable in both cases.

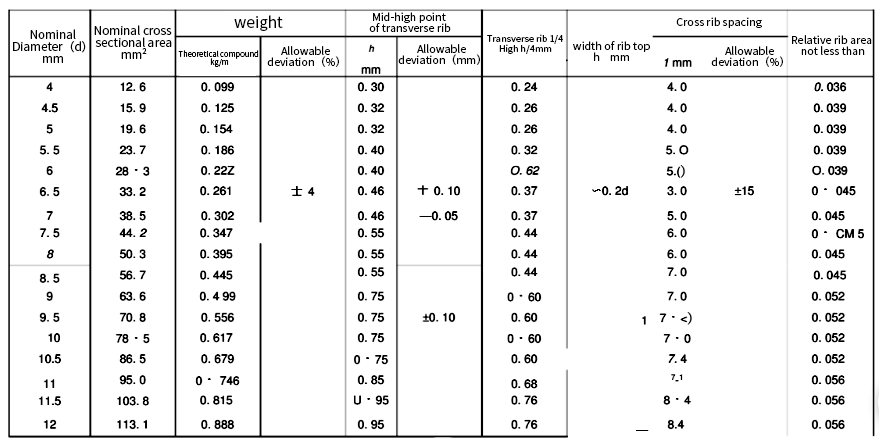

The following are their specification sizes:

1. Nominal diameter range

The nominal diameters of CRB550, CRB600H, and CRB680H steel bars range from 4mm to 12mm, while the nominal diameters of CRB650, CRB800, and CRB800H bars are 4mm, 5mm, and 6mm.

2. Length

Reinforcing bars are usually delivered in coils, or in fixed lengths. When the steel bars are delivered in fixed lengths, the lengths and allowable deviations are determined by mutual agreement between supply and demand.

3. Bending degree

The bending degree of straight bars is not more than 4mm per meter, and the total bending degree is not more than 0.4% of the total length of the bars.

4. Weight

Each rebar should be composed of one rebar, and the weight of the reel is not less than 100kg.

Schedule, including size, quality and allowable deviation. The size, quality and permissible deviation of the three-sided rib and two-sided rib reinforcement shall conform to the following table.