A steel pipe is a steel material with a hollow section whose length is much greater than its diameter or circumference. Steel pipes have the advantages of high strength and durability, and those pipes are easy to cut, weld, and form. Steel pipe is widely used in construction, energy, transportation, machinery manufacturing, etc. It plays an important role in the infrastructure construction and industrial development of modern society.

There are many types of steel pipes. According to the production process, steel pipes are divided into seamless and welded steel pipes. According to the cross-sectional shape of the steel pipe, it can be divided into round and special-shaped pipes. In addition to these two classification methods, there are many other classification methods for steel pipes, such as according to material and purpose.

Ⅰ Seamless Steel Pipe and Welded Steel Pipe

According to the production process, steel pipes are divided into seamless and welded steel pipes. Seamless steel pipes are divided into hot-rolled and cold-rolled (cold-drawn). Welded steel pipes are divided into straight-seam welded steel pipes and spiral-seam welded steel pipes.

Seamless steel pipe is made of whole round steel with holes and no welds on the surface. In terms of material, seamless steel pipes are generally made of 10#(ASTM 1010), 20#(ASTM 1020), 30#(ASTM 1030), 35#(ASTM 1034), 45#(ASTM 1045), etc.; high-quality carbon steel 16Mn, 5MnV, etc.; low-alloy structural steel or 40Cr(ASTM 5140), 45Mn2(ASTM 1345), and other alloy steels, as well as stainless acid-resistant steels.

Seamless steel pipes are widely used. According to their uses, they are divided into general-purpose (used for water, gas pipelines structural parts, mechanical parts) and special-purpose (used for boilers, geological exploration, bearings, acid resistance, etc.).

The production processes of cold-rolled seamless steel pipes and hot-rolled steel pipes are different.

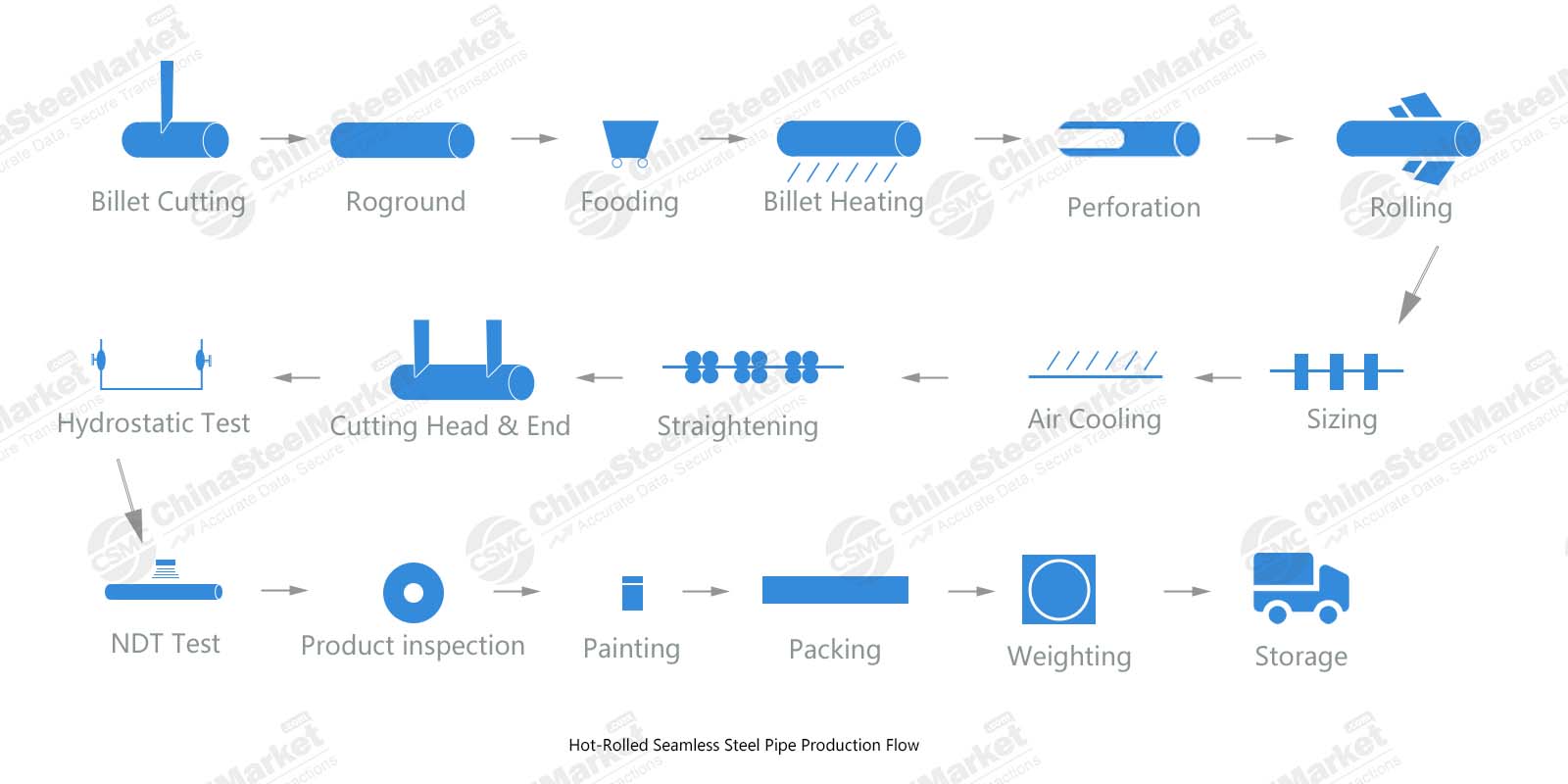

①Hot-rolled Seamless Steel Pipe:

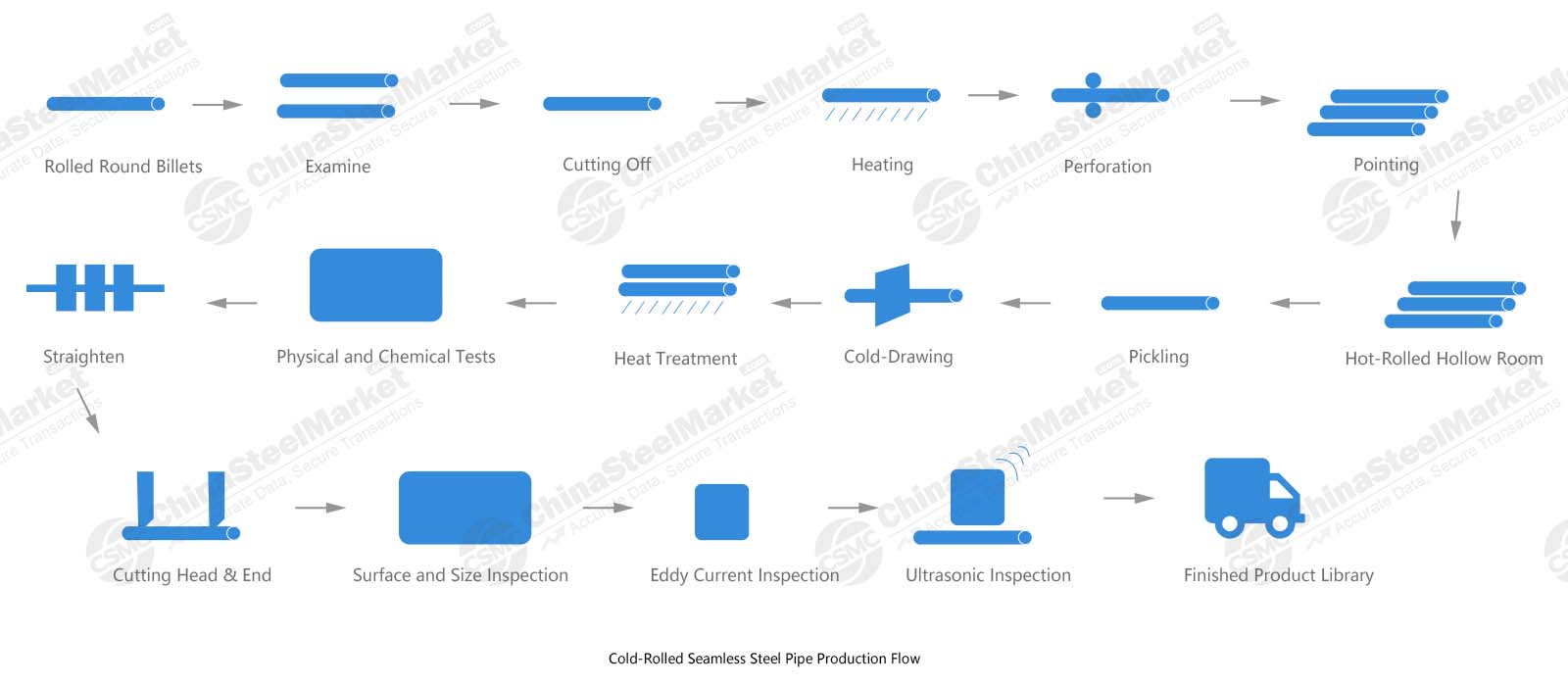

②Cold-rolled (cold-drawn) Seamless Steel Pipe:

In addition to the production process, cold-rolled steel pipes and hot-rolled steel pipes also have many other differences.

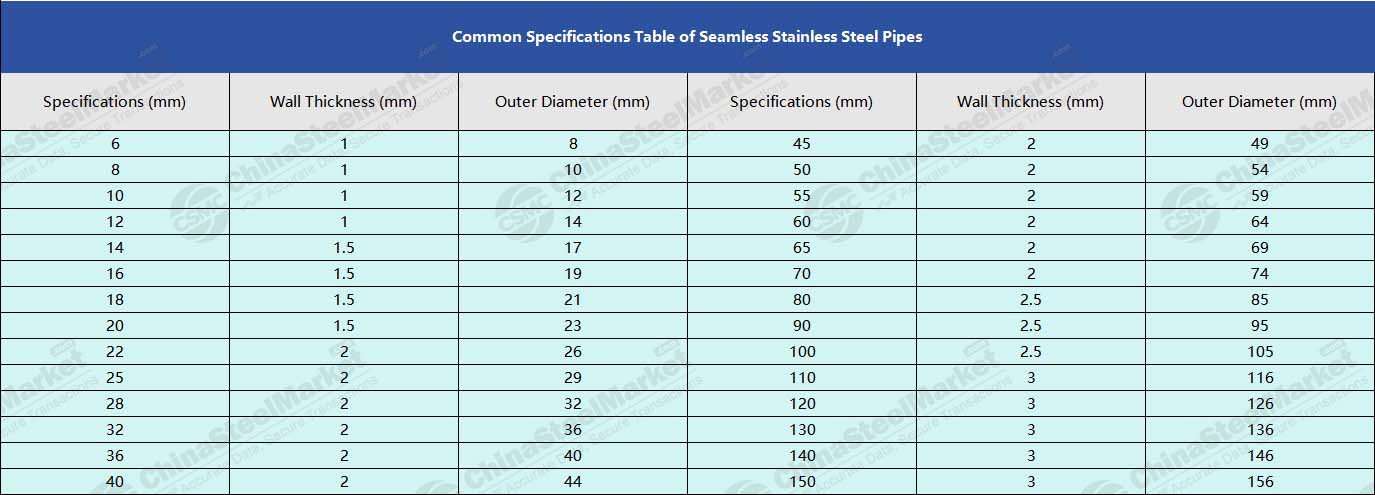

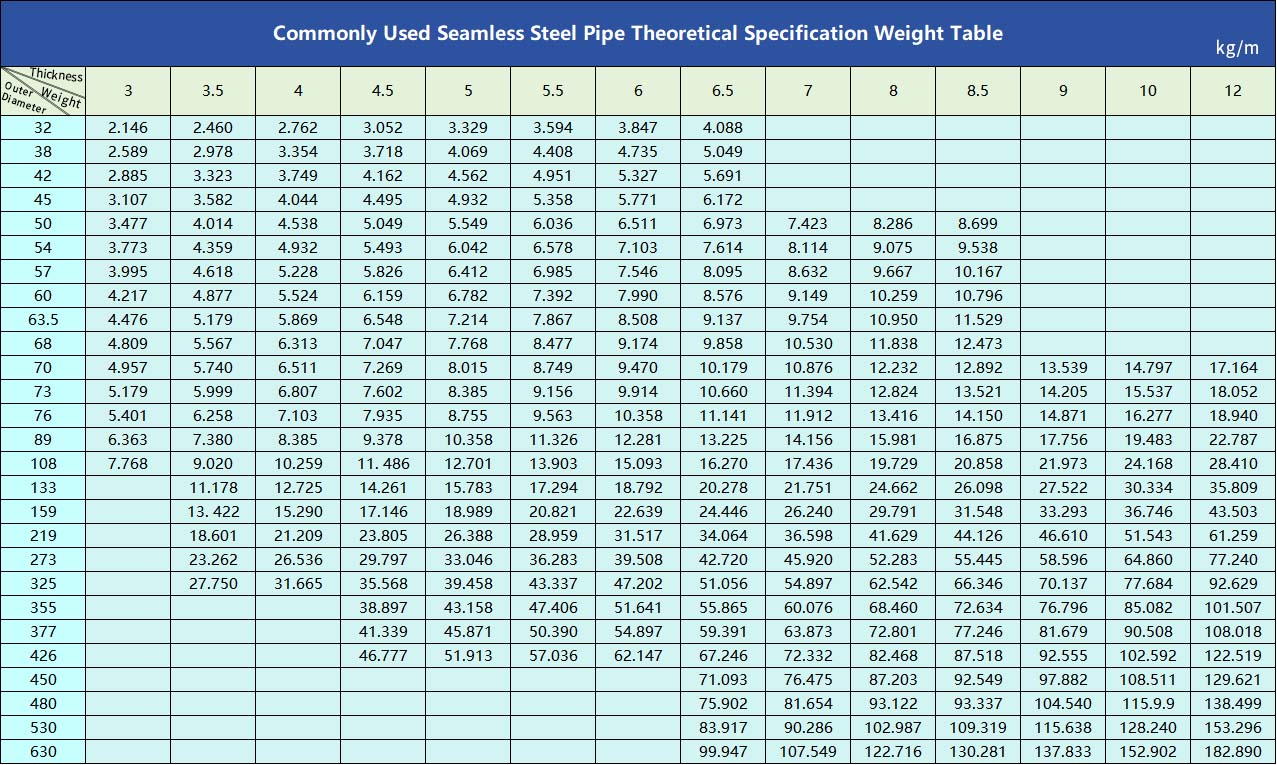

Generally speaking, cold-rolled seamless steel pipes are shorter than hot-rolled seamless steel pipes; the wall thickness of cold-rolled seamless steel pipes is generally smaller than that of hot-rolled seamless steel pipes. For example, the outer diameter of hot-rolled seamless pipes is generally greater than 32mm, and the wall thickness is 2.5-200mm; the outer diameter of cold-rolled seamless steel pipes can reach 6mm, the wall thickness can reach 0.25mm, and the outer diameter of thin-walled pipes can reach 5m, and the wall thickness is less than 0.25mm.

The surface of cold-rolled seamless steel pipes looks brighter, the surface is not too rough, and the diameter does not have too many burrs. The delivery state of hot-rolled seamless steel pipes is generally delivered after hot rolling and heat treatment.

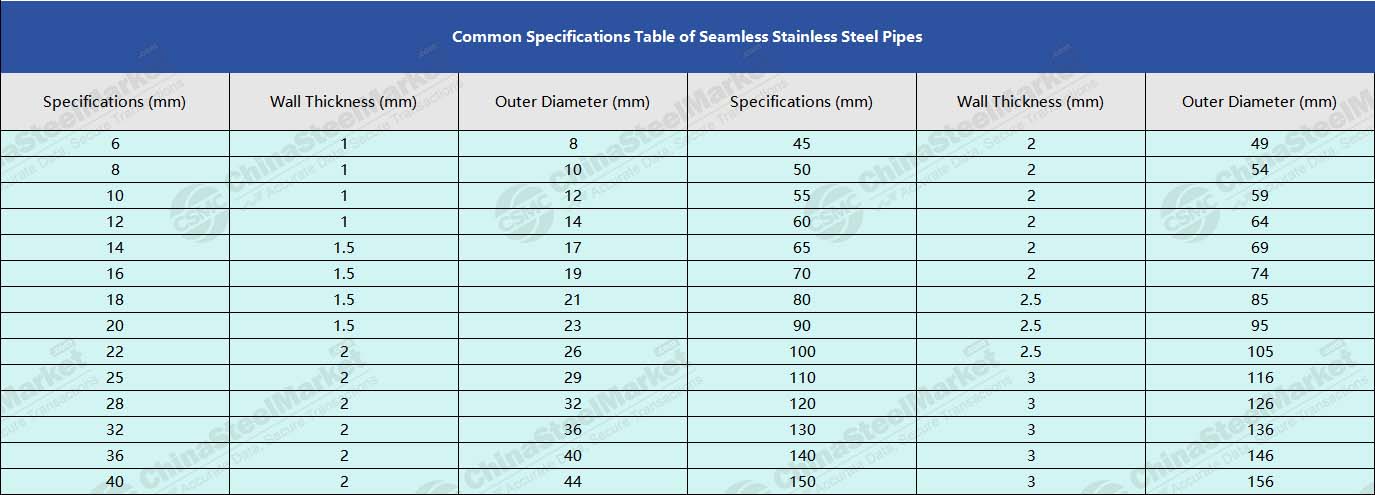

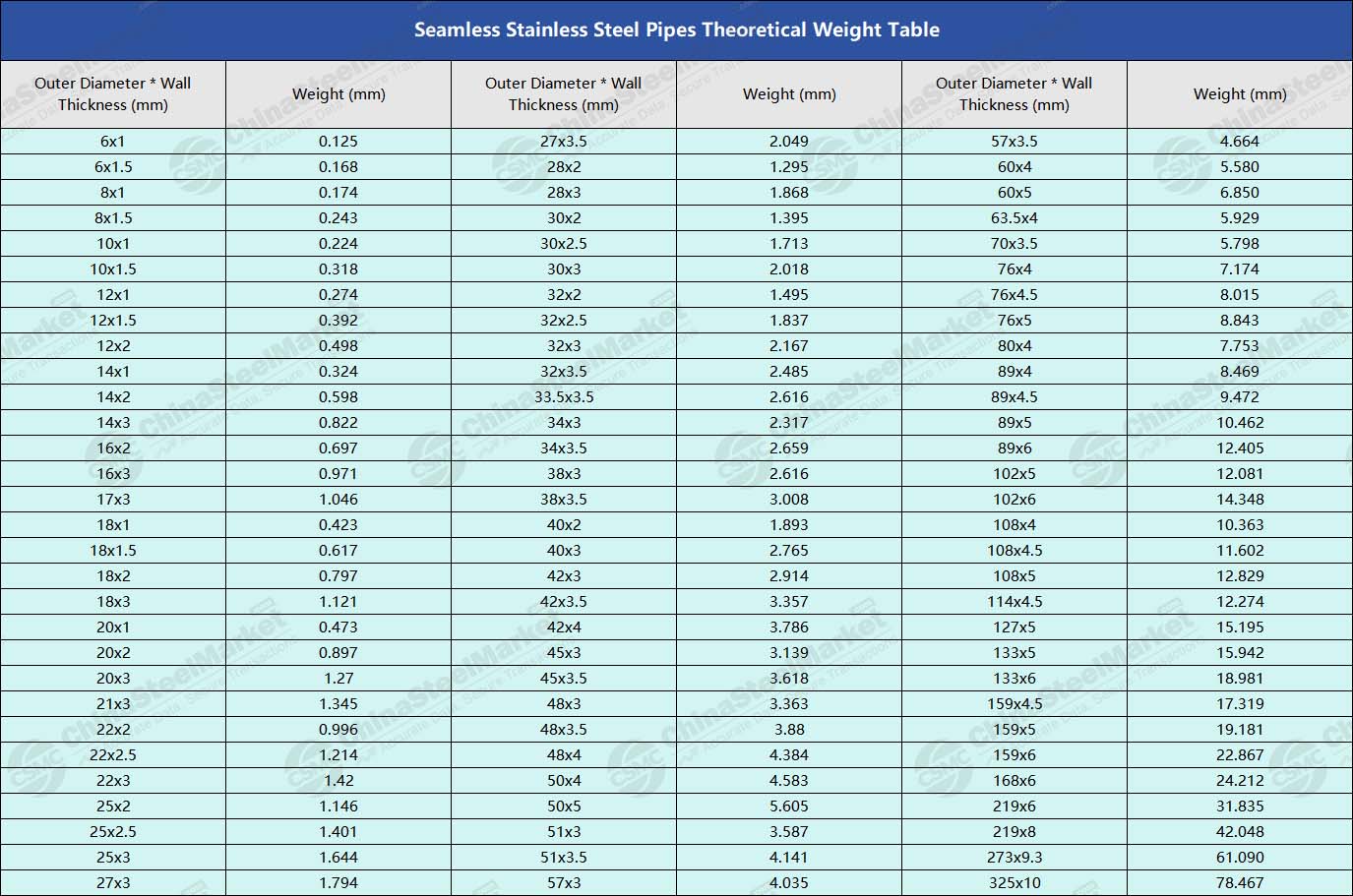

The following is a detailed introduction to the specifications of seamless steel pipes:

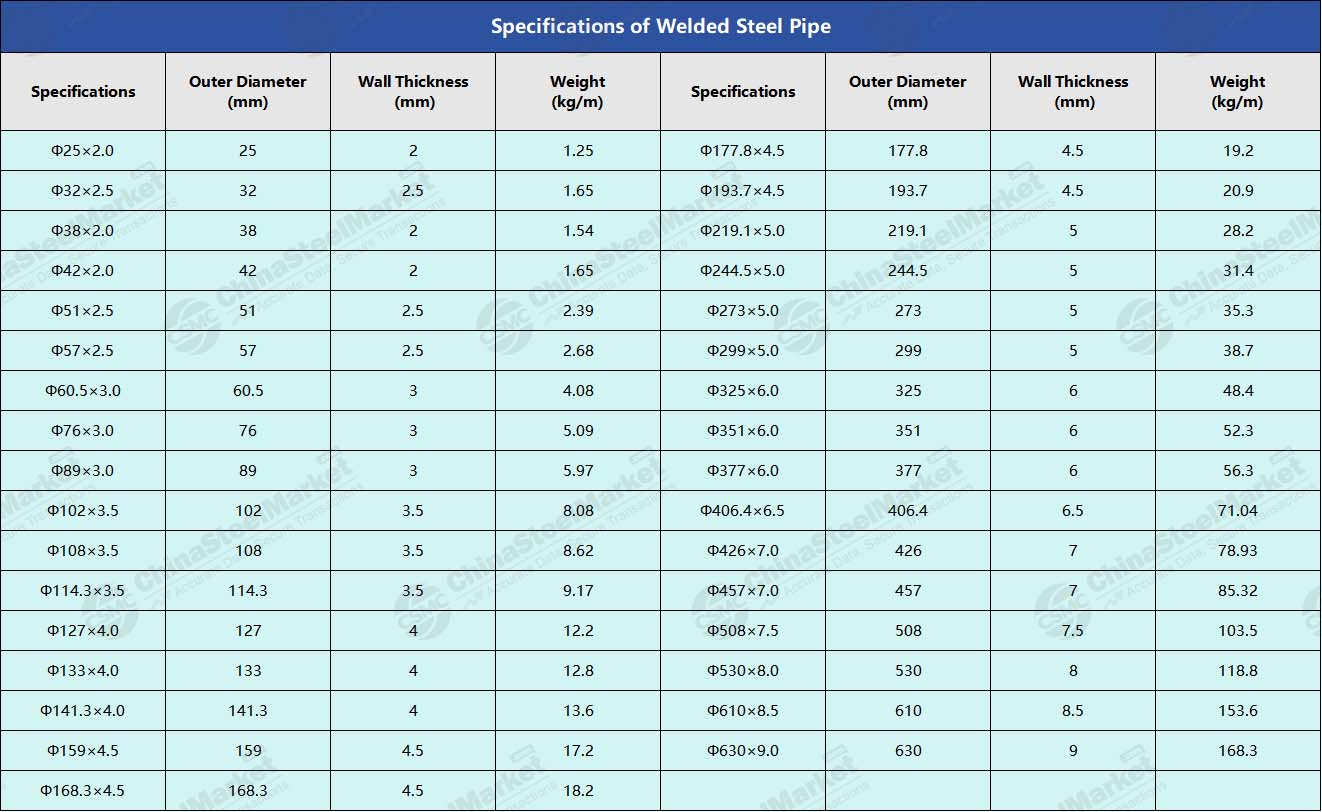

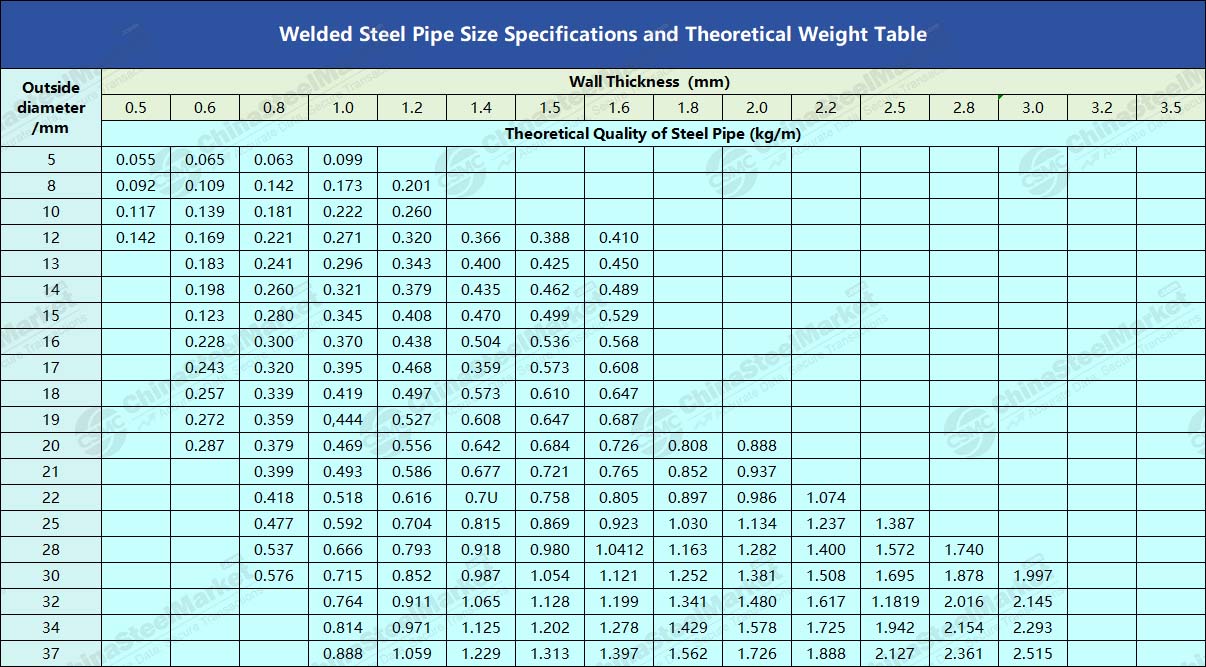

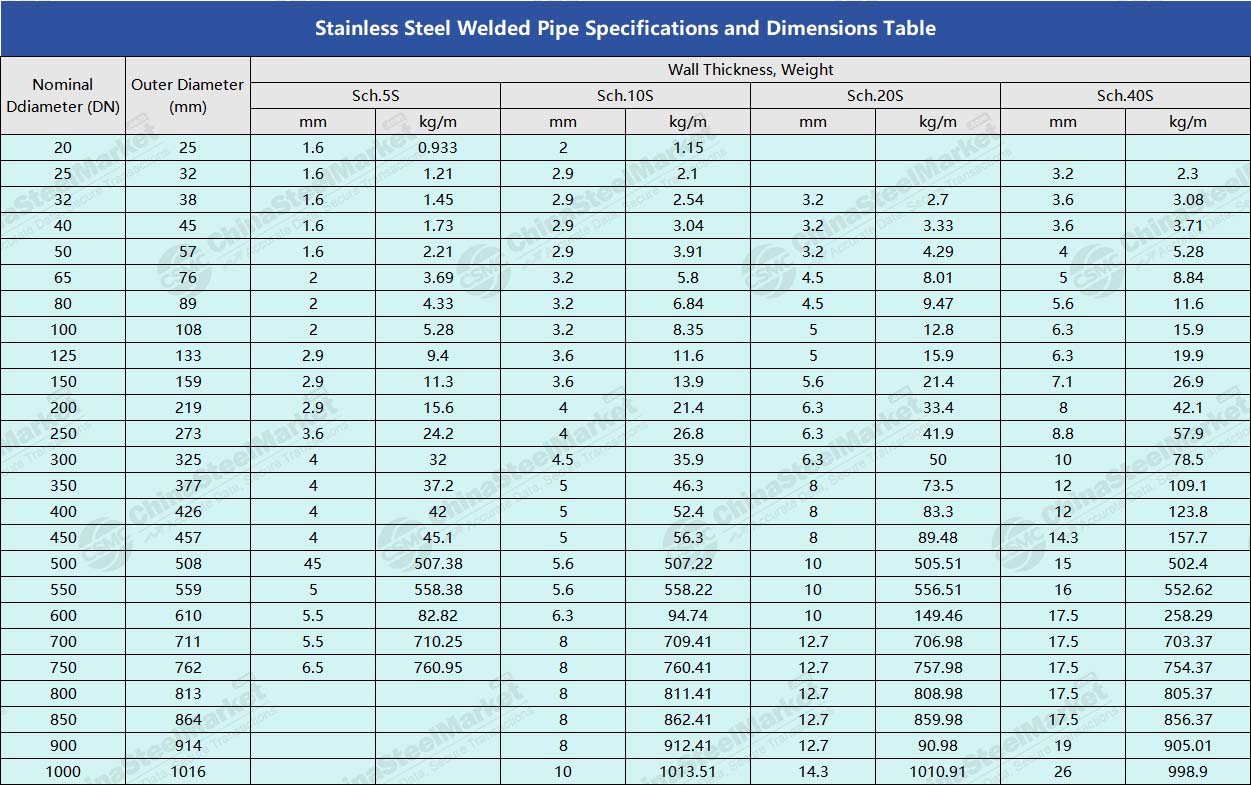

Welded steel pipe refers to a steel pipe with seams on the surface that is formed by bending steel strips or steel plates into round, square, and other shapes and then welding them. The billet used for welded steel pipes is steel plate or strip steel.

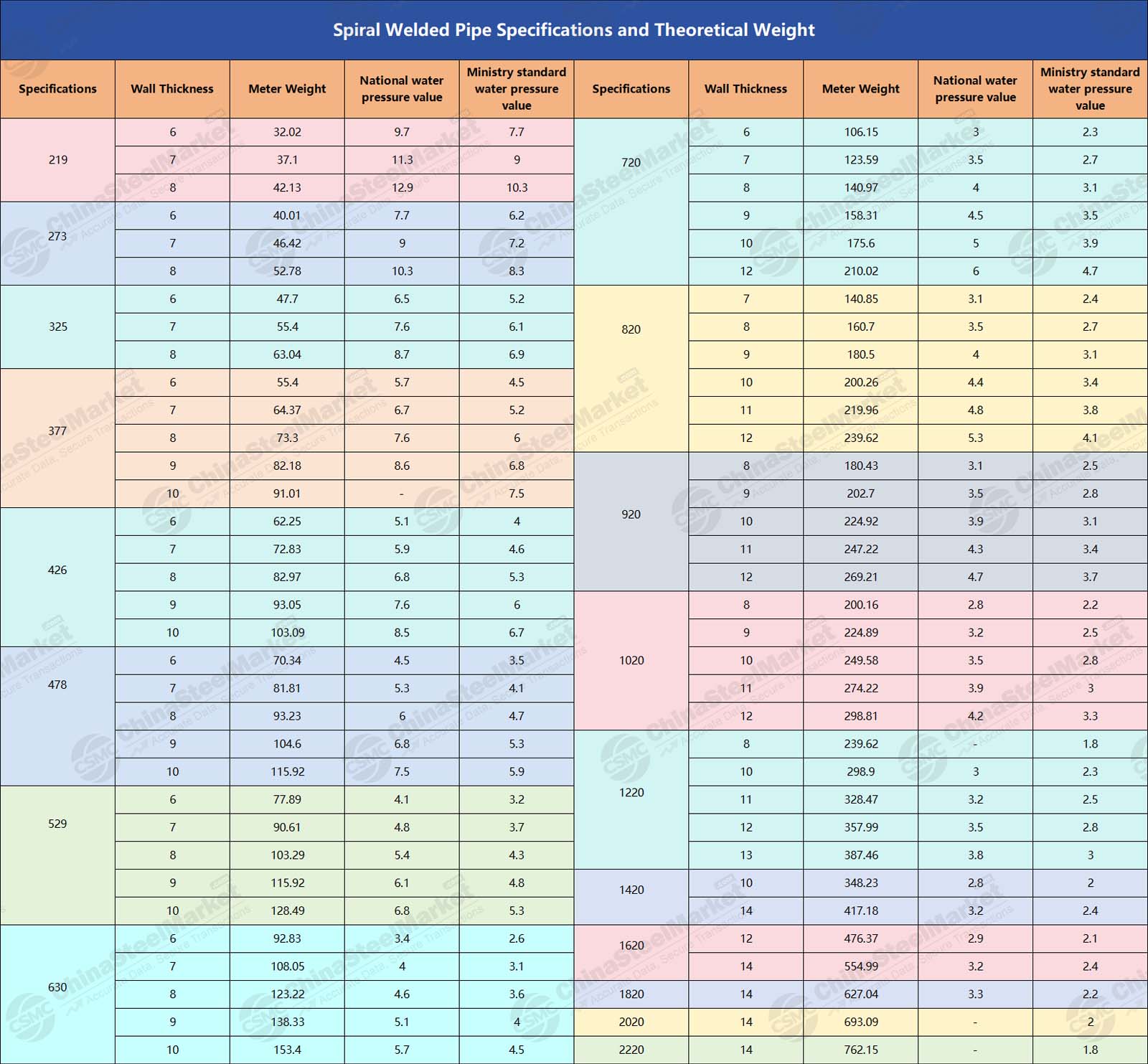

Welded steel pipes can be divided into straight-seam welded pipes and spiral welded pipes according to the shape of the weld. The production process of straight seam welded pipes is simple, the production efficiency is high, the cost is low, and the development is rapid. The outer diameter of straight seam welded pipes is generally DN15 (1/2"*2.75mm)-DN150 (6"*4.5mm). The strength of spiral welded pipes is generally higher than that of straight seam welded pipes. It can produce welded pipes with larger diameters with narrower billets, and can also produce welded pipes with different diameters with billets of the same width.

Ⅱ Round Tubes and Special-shaped Tubes

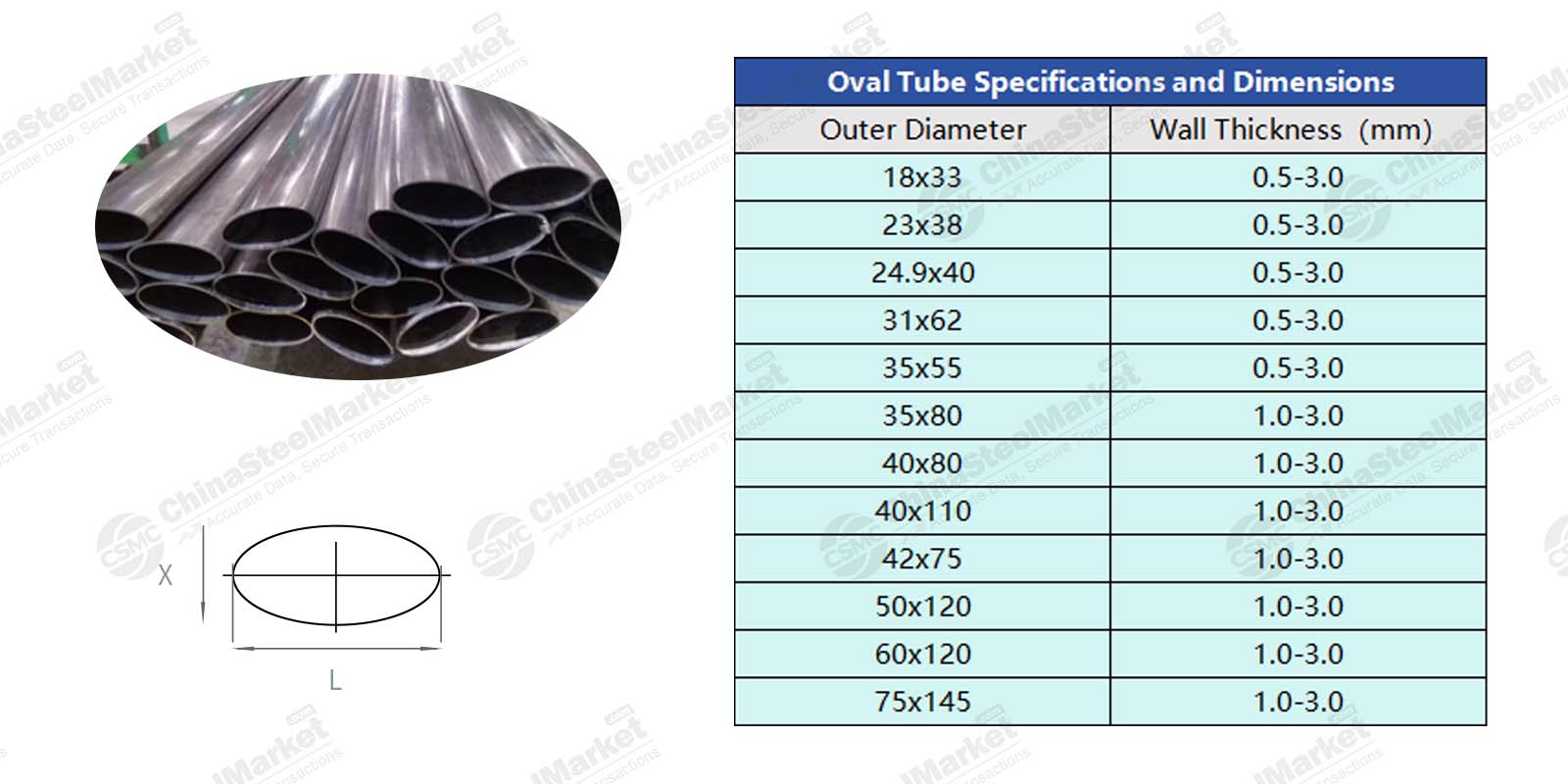

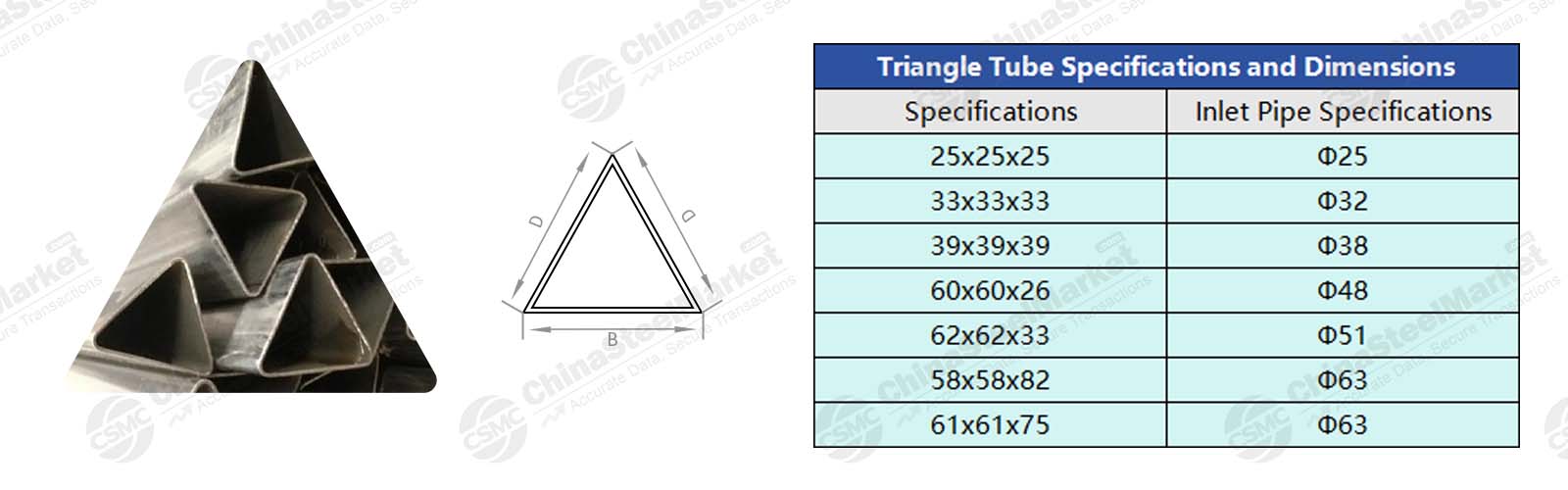

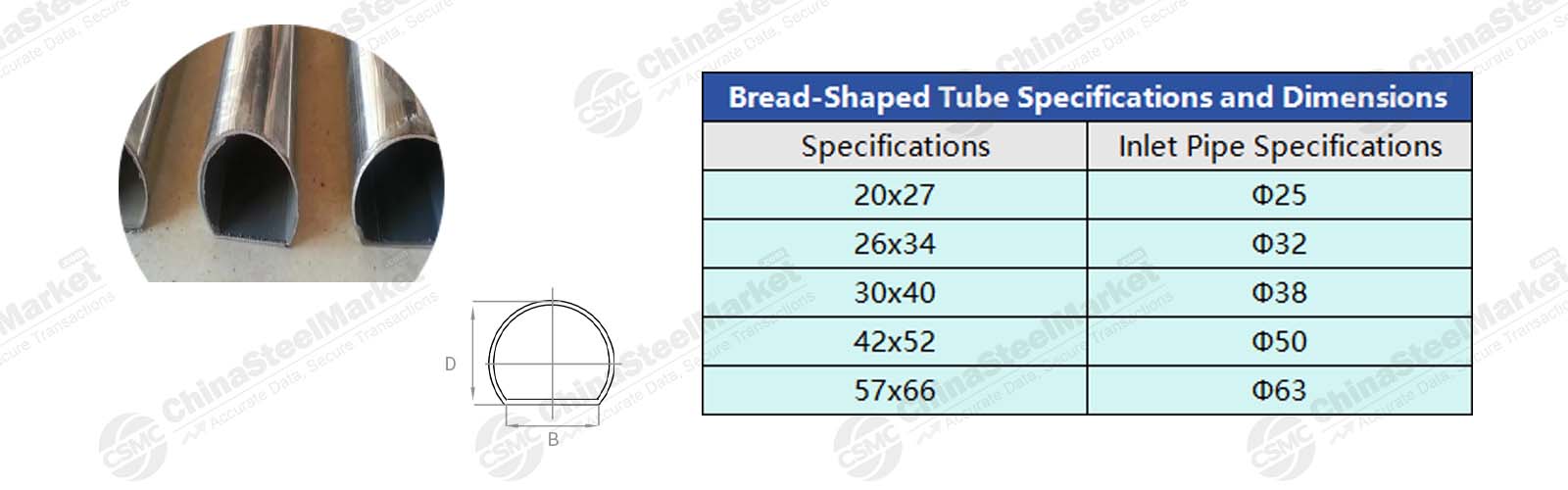

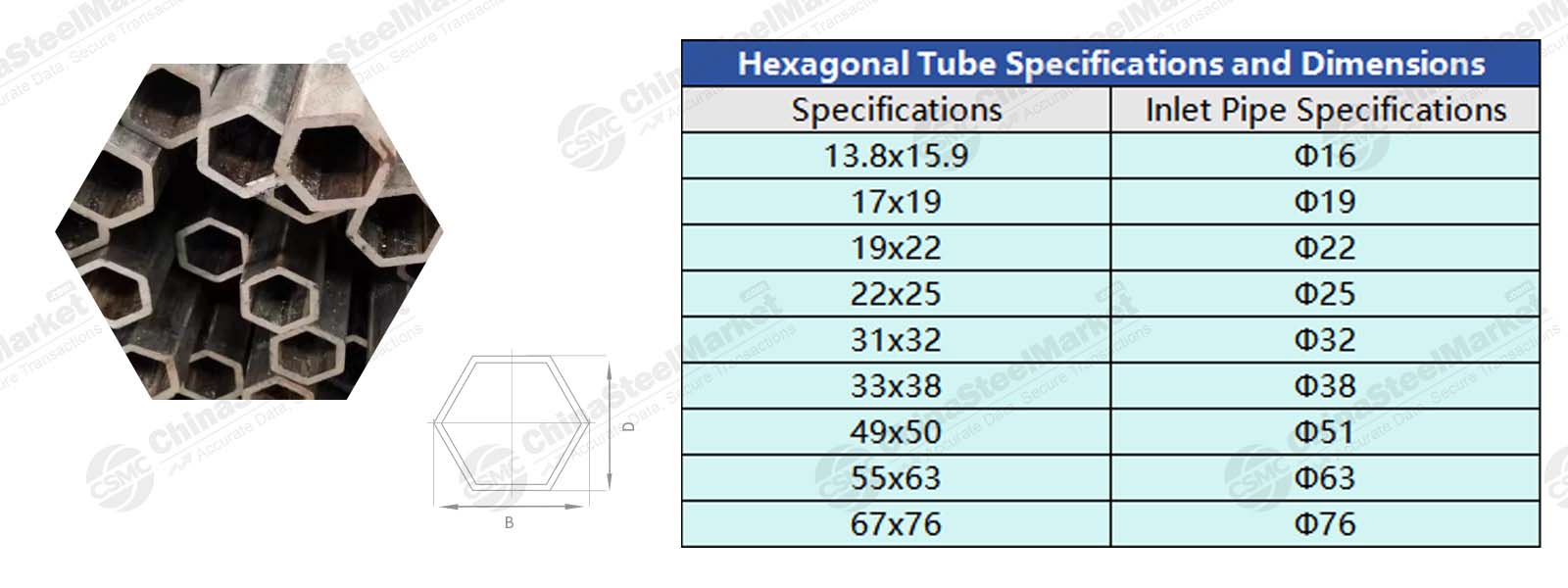

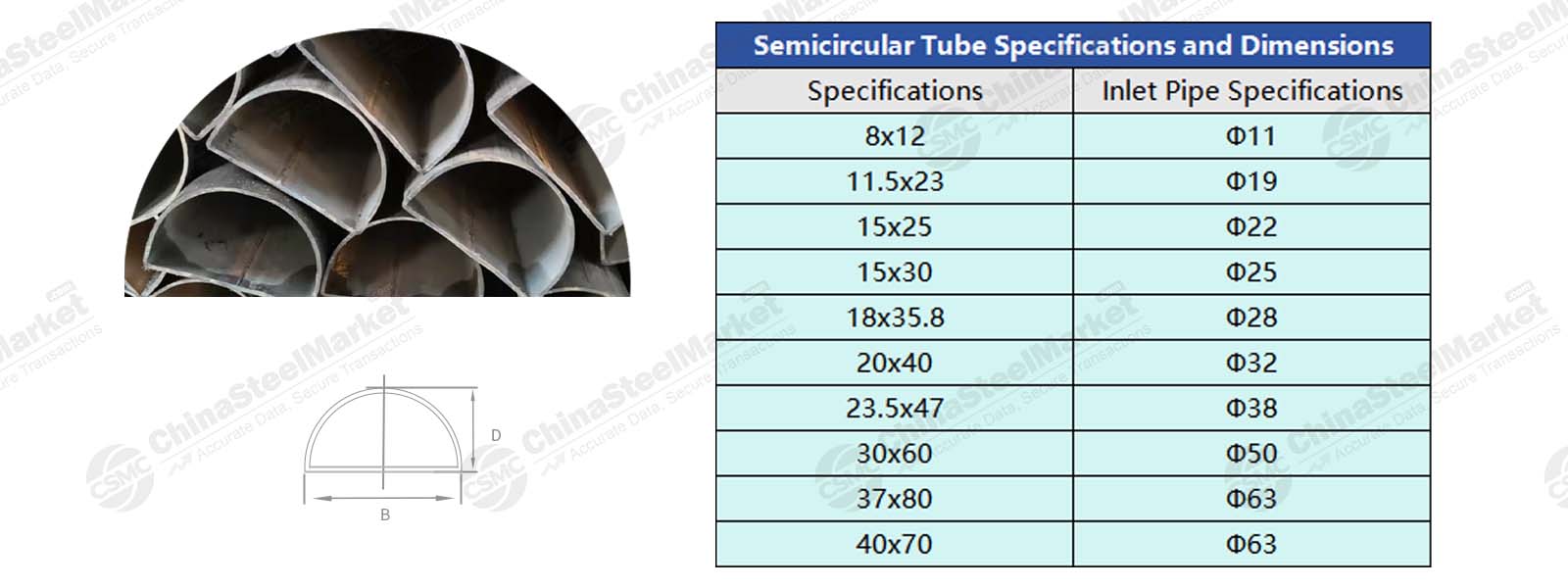

Steel tubes can be divided into round steel tubes and special-shaped steel tubes according to the cross-sectional shape. Special-shaped steel tubes refer to various steel tubes with non-circular cross-sections. Special-shaped seamless steel tubes have greater bending and torsion resistance and can greatly reduce the weight of the structure. It is widely used in various structural parts, tools, and mechanical parts.

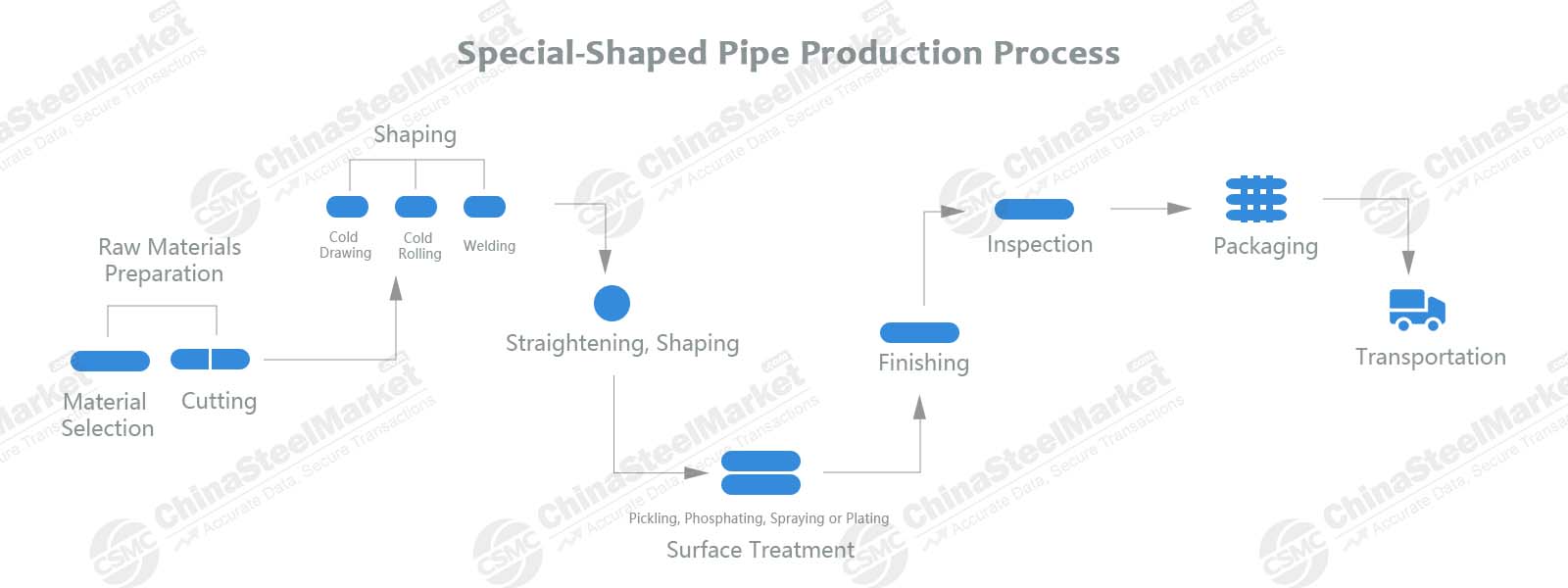

Extrusion, oblique die rolling, and cold drawing are effective methods for producing special-shaped tubes. The process of producing special-shaped steel tubes is relatively complicated and requires a combination of multiple processes.

Special-shaped steel pipes are mainly made of seamless pipes. So, special-shaped seamless steel pipes are the general term for seamless steel pipes with other cross-sectional shapes except round pipes. There are mainly square pipes, rectangular pipes, elliptical pipes, flat elliptical pipes, semicircular pipes, hexagonal pipes, equilateral triangle pipes, octagonal pipes, etc.

Due to the complexity of the production and shape of special-shaped pipes, the anti-corrosion measures for special-shaped pipes are very important. The following are the anti-corrosion measures for special-shaped pipes.

1) Apply asphalt paint to the special-shaped pipe layer.

2) Cement mortar lining + special coating.

3) Apply epoxy coal tar to the special-shaped pipe layer.

4) Epoxy ceramic lining.

5) Aluminate cement coating and sulfate cement coating.

6) Apply polyurethane to the special-shaped pipe layer.

Ⅲ Carbon Steel Pipe and Stainless Steel Pipe

According to the material, steel pipes can be mainly divided into carbon pipes, alloy pipes, and stainless steel pipes. The classification of stainless steel pipes is roughly similar to the carbon steel pipes introduced above, but the material is different.

Stainless steel pipe is a hollow long cylindrical steel. Its application range is used as a pipeline for conveying fluids. It is widely used in the fields of petroleum, chemical, medical, food, etc.

Stainless steel pipes have excellent corrosion resistance and can resist oxidation, pickling, salt corrosion, and other corrosion. In addition, stainless steel pipes also have good high-temperature resistance and can be used for a long time at high temperatures. Stainless steel pipes have high tensile strength and compressive strength and can withstand greater weight and pressure. In addition, stainless steel pipes also have good plasticity and weldability, as well as a bright and smooth surface.

As China's stainless steel pipe production technology matures, the specification data sheets of stainless steel pipes are also being continuously improved.

IV Data Analysis of China's Steel Pipe Industry

In 2004, China ranked first in the world in steel pipe production, becoming the world's largest steel pipe producer. Since 2012, China's steel pipe production has accounted for more than 50% of the world's total steel pipe production, and China's steel pipe production capacity is at the forefront of the world.

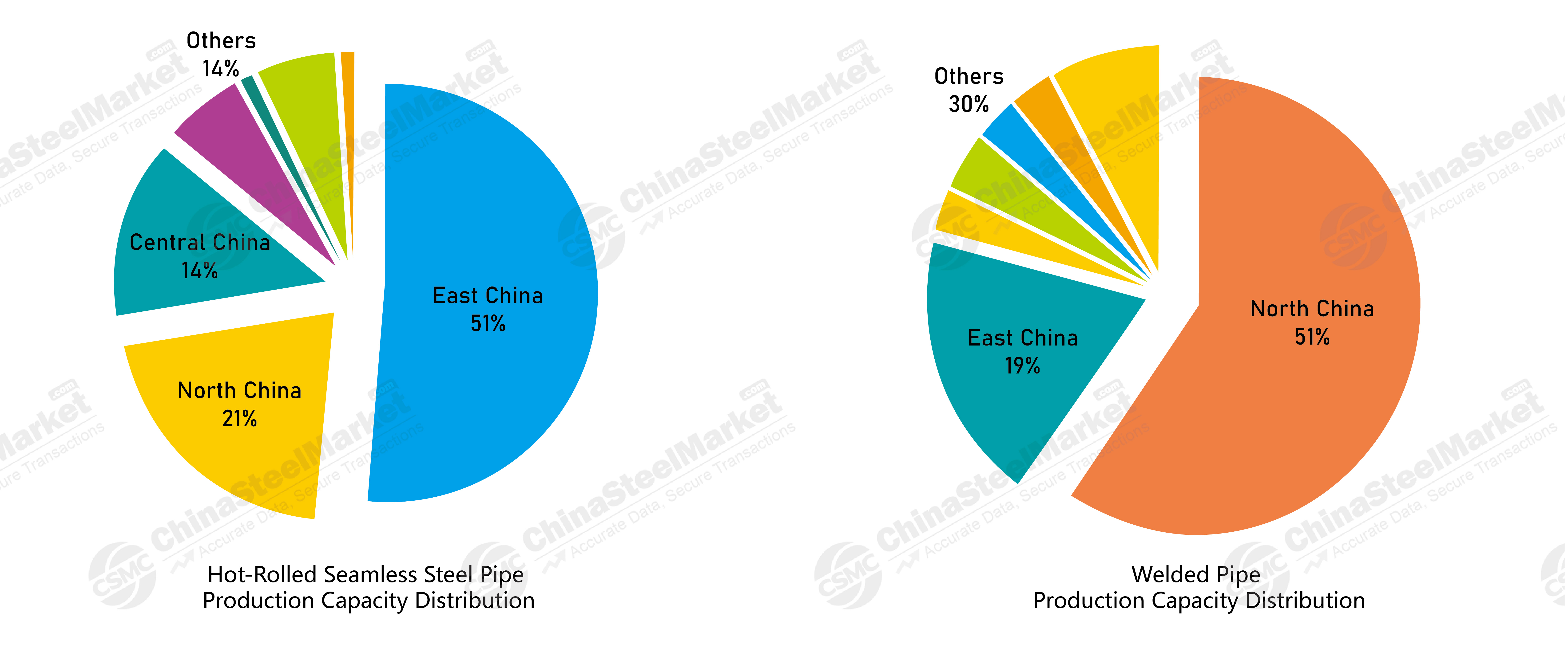

At present, China has a complete range of steel pipe production machines and advanced technology. The specifications, varieties, quality, and services of steel pipes can meet market demand. The international market competitiveness of steel pipes has also been significantly improved. North China and East China are the two major production areas of China's steel pipe industry and are also the main areas for China's steel pipe production and processing. Among them, Tianjin ranks first in welded pipe production capacity, and Shandong ranks first in seamless pipe production capacity. Liaocheng, Shandong is known as the capital of China's steel pipes.

The East China region has a good industrial foundation. The steel pipe varieties and specifications of steel pipe enterprises in Shandong, Jiangsu, Zhejiang, and Shanghai are relatively complete, and the equipment level is generally better than the national average. Their product quality, production technology, and marketing capabilities are also higher than other regions in China. The seamless steel pipe production capacity in East China accounts for about 51% of the country, and the welded pipe production capacity accounts for about 21% of the country. It has formed an industrial cluster with a complete range of products, complete upstream and downstream supporting facilities, and mature market cultivation. East China is also a region where the production of high-end products such as stainless steel pipes is relatively concentrated in my country. Steelpipe enterprises are diverse, and the production scale is matched. There is a clear market segmentation and a stable and reliable environment, and it has a good industrial structure.

North China is the main production area of welded pipes in China. Its production capacity is mainly concentrated in Tianjin, Hebei, Shanxi, and other places. The production capacity of welded pipes accounts for about 60% of the country; the production capacity of seamless steel pipes accounts for about 21% of the country.

In 2013, the Chinese President proposed the "One Belt, One Road" economic policy. Under the advocacy of the policy, Chinese steel pipe companies have opened many steel pipe plants in North America, Southeast Asia, the Middle East, Africa, and other places. After 2023, Chinese steel pipe companies have actively developed and increased their investment in production technology. Enterprises continue to make breakthroughs and innovations in technology, processes, production costs, and product benefits to meet market demand.

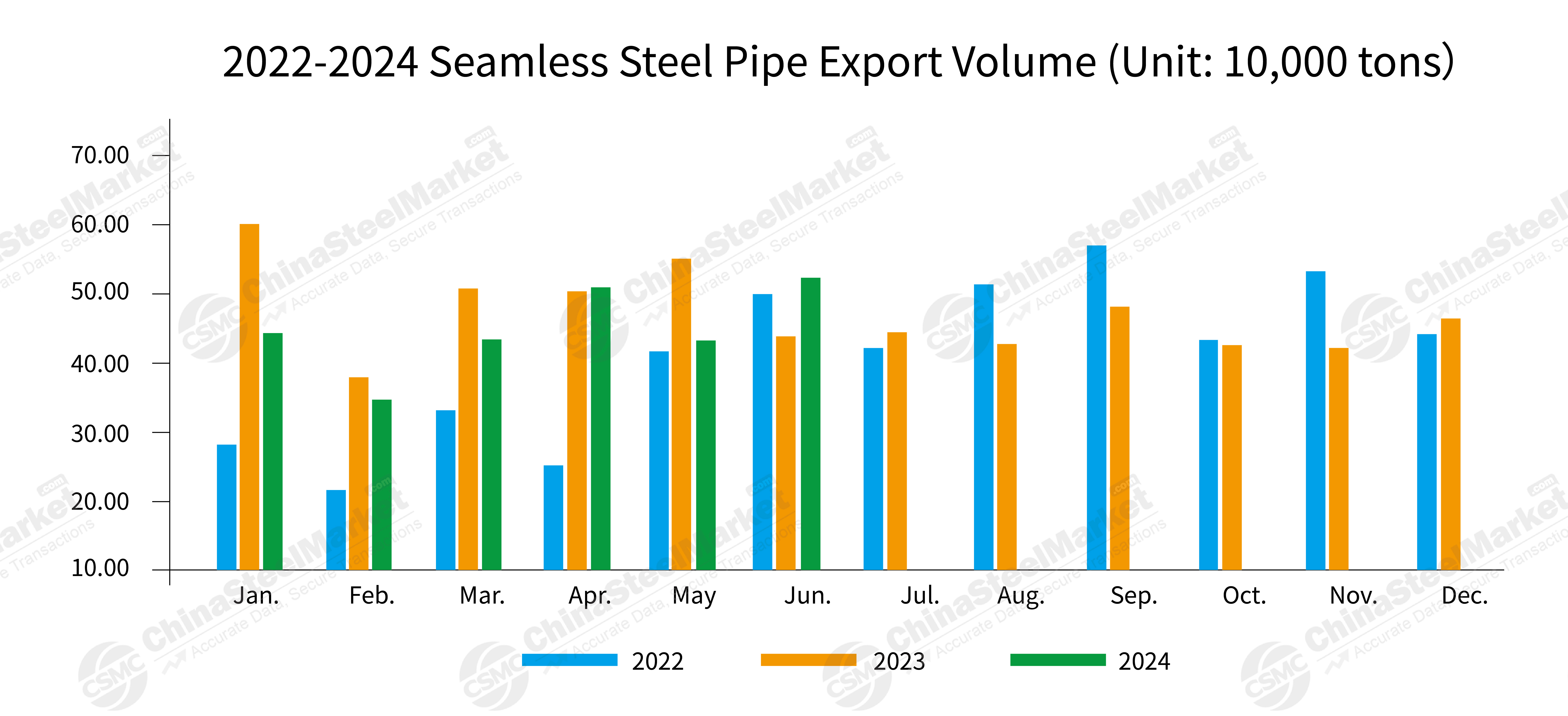

According to data released by the General Administration of Customs, China exported 8.745 million tons of steel in June 2024, a decrease of 886,000 tons compared with the previous month, a month-on-month decrease of 9.2%; the cumulative steel exports from January to June were 53.40 million tons, a year-on-year increase of 24.0%; China exported 518,600 tons of seamless pipes in June 2024, a month-on-month increase of 20.55% and a year-on-year increase of 16.28%; China's cumulative exports of seamless pipes from January to June were 2.6838 million tons, a year-on-year decrease of 10.47%.

From the data, China's seamless steel pipe exports showed a sharp decline year-on-year from January to May 2024. The main reason is that there are signs of slowing down in new international oil and gas-related investment projects, and the demand for oil and gas drilling seamless pipes and boiler pipes has dropped sharply. With the adjustment of overseas demand structure and policy influence, China's seamless steel pipe exports will inevitably be affected to a certain extent. However, opportunities and challenges coexist. Changes in the demand structure of foreign markets will also force China to accelerate the process of industrial transformation and upgrading and become the driving force for the innovative development of China's steel pipe industry.

Although China's steel pipe export trend has declined, China's steel pipe production capacity is still at the forefront of the world. The number of types and production processes of steel pipes are still leading the world. More importantly, China's cargo transportation safety and convenience are superior to those of other countries. So China is still the first choice for steel pipe importing countries.

Under the influence of various international and domestic factors, the development of the world industry will also face certain challenges and opportunities in the future. CSMC will also continue to pay attention to the development of the steel industry and actively provide useful information to customers.

We sincerely hope that the information we provide can make more beneficial value. In addition, we sincerely invite you to leave valuable comments and advice on our website. We will follow your comments and advice at any time on our website.

CSMC-Empowering small and medium-scale steel purchasing.

Editor: Gianna Hana

Mail: gianna@chinasteelmarket.com

|

|

|

|

|

| Timely Info | Independent | Platform | Multiple guarantees | Self-operated storage |

| About us | Channel | Useful tools |

|---|---|---|

| About China Steel Market | Prices | Steel weight calculation |

| Contact us | Answers | |

| Terms & Conditions | Inventory | |

| Privacy Policy | Help |

Hot search words: