Stainless steel, also known as stainless acid-resistant steel, water copper iron. From a metallurgical definition, it refers to alloy steel that is passive, corrosion-resistant, rust-free, and contains a high concentration of chromium (12%~30%) in the atmosphere and corrosive media such as acids, alkalis, and salts. Usually, it also contains elements such as nickel, molybdenum, vanadium, manganese, and tungsten. The most important metal element that makes stainless steel rust-proof is chromium. If stainless steel is defined based on the content of its chemical components, stainless steel is an alloy steel with a minimum chromium content of 10.5 wt% and a maximum carbon content of 1.2 wt%. Otherwise, it is an "iron alloy" with a chromium content exceeding 10%. It is called stainless steel because it does not corrode and rust as easily as ordinary steel.

Common stainless steel classifications include martensitic steel, ferritic steel, austenitic steel, duplex stainless steel, etc. There are many different stainless steel models under each classification. This article lists the model names of various stainless steel materials.

Stainless steel is divided into five categories according to its crystal structure: austenitic stainless steel (A1, A2, A3, A4, A5), ferritic stainless steel (F1), martensitic stainless steel (C1, C4, C3), duplex stainless steel and prescription hardening grade stainless steel.

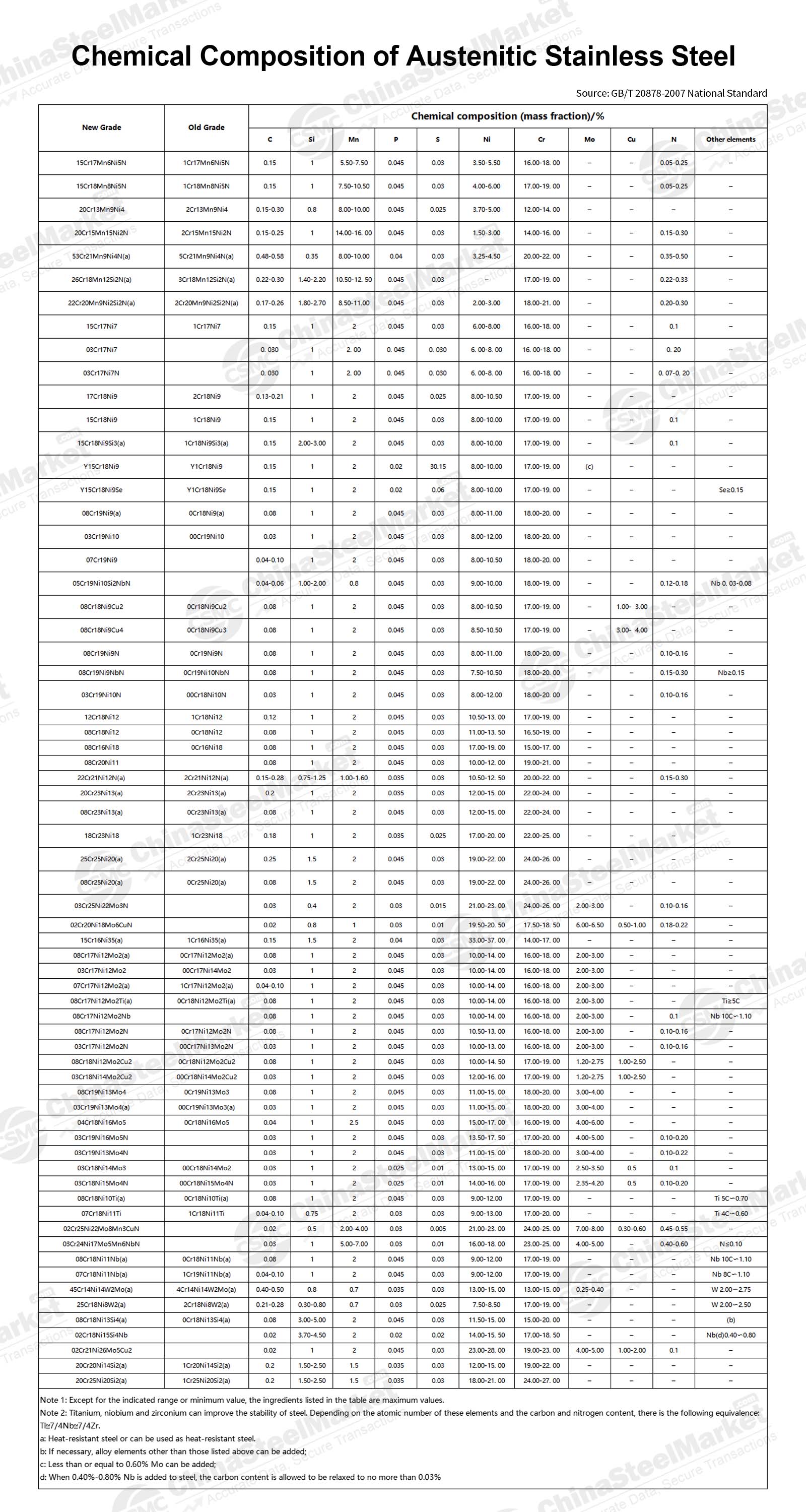

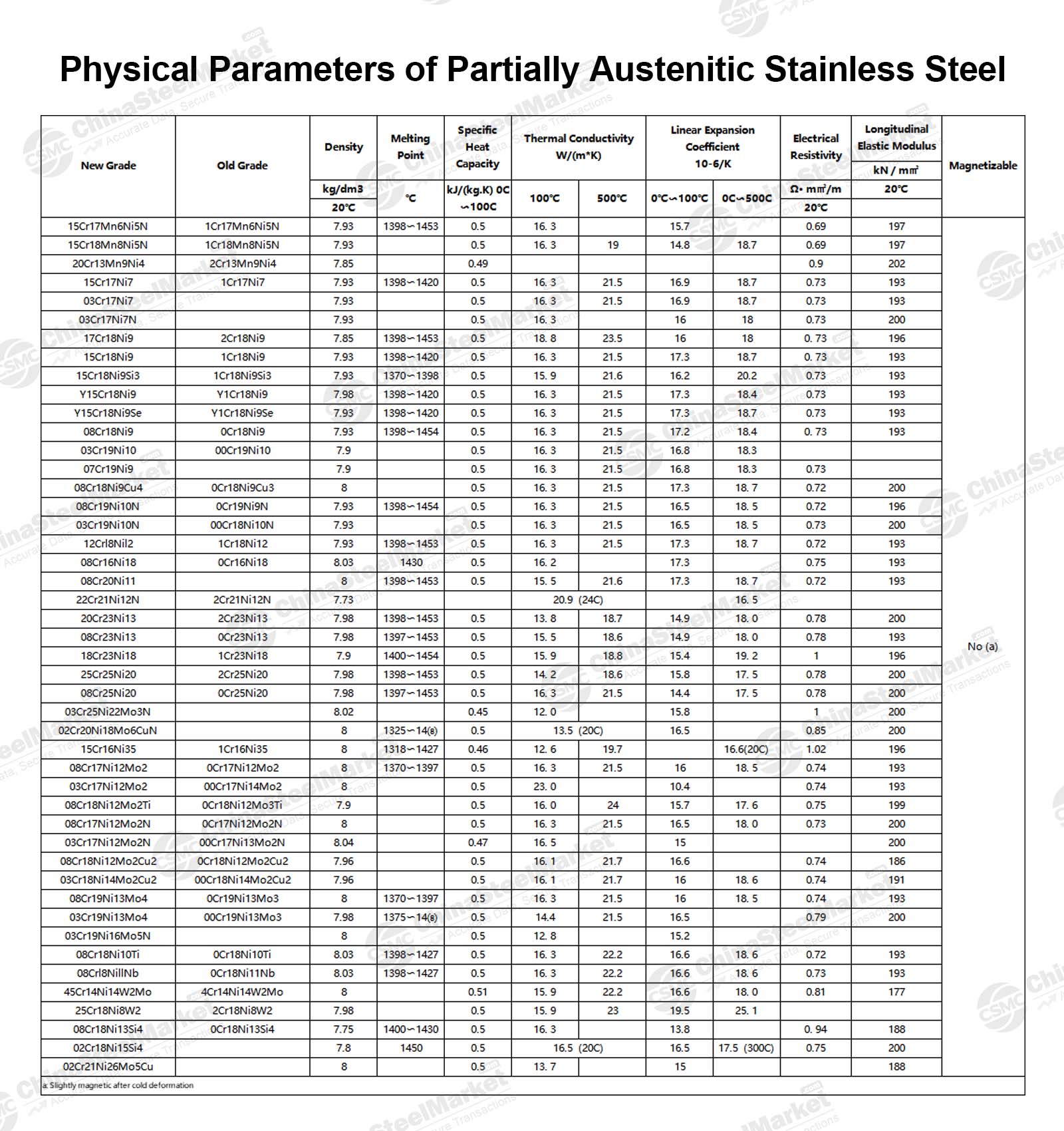

Ⅰ Austenitic Stainless Steel

Austenitic stainless steel contains 16%-26% chromium and less than 35% nickel and generally has the highest corrosion resistance. It cannot be strengthened by heat treatment and is non-magnetic. Its applications include the aircraft industry, dairy, and food processing industries.

Chemical Composition

Physical Properties

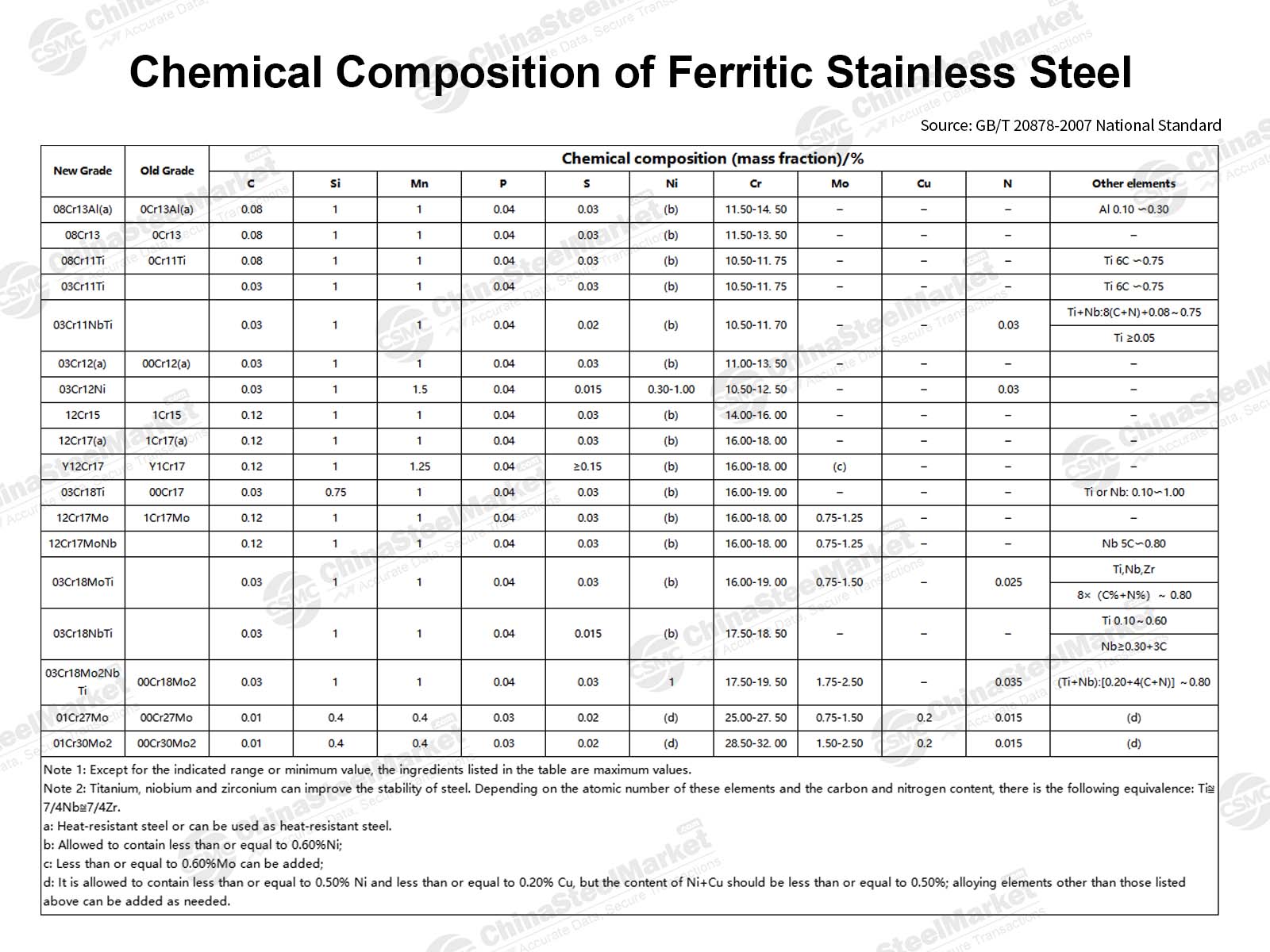

Ⅱ Ferritic Stainless Steel

Ferritic stainless steel refers to stainless steel materials with a chromium content between 10.5% and 30%, a body-centered cubic grain structure, and a main ferrite structure. Since this body-centered cubic grain structure is typical of alpha iron, ferritic stainless steel is magnetic.

Chemical Composition

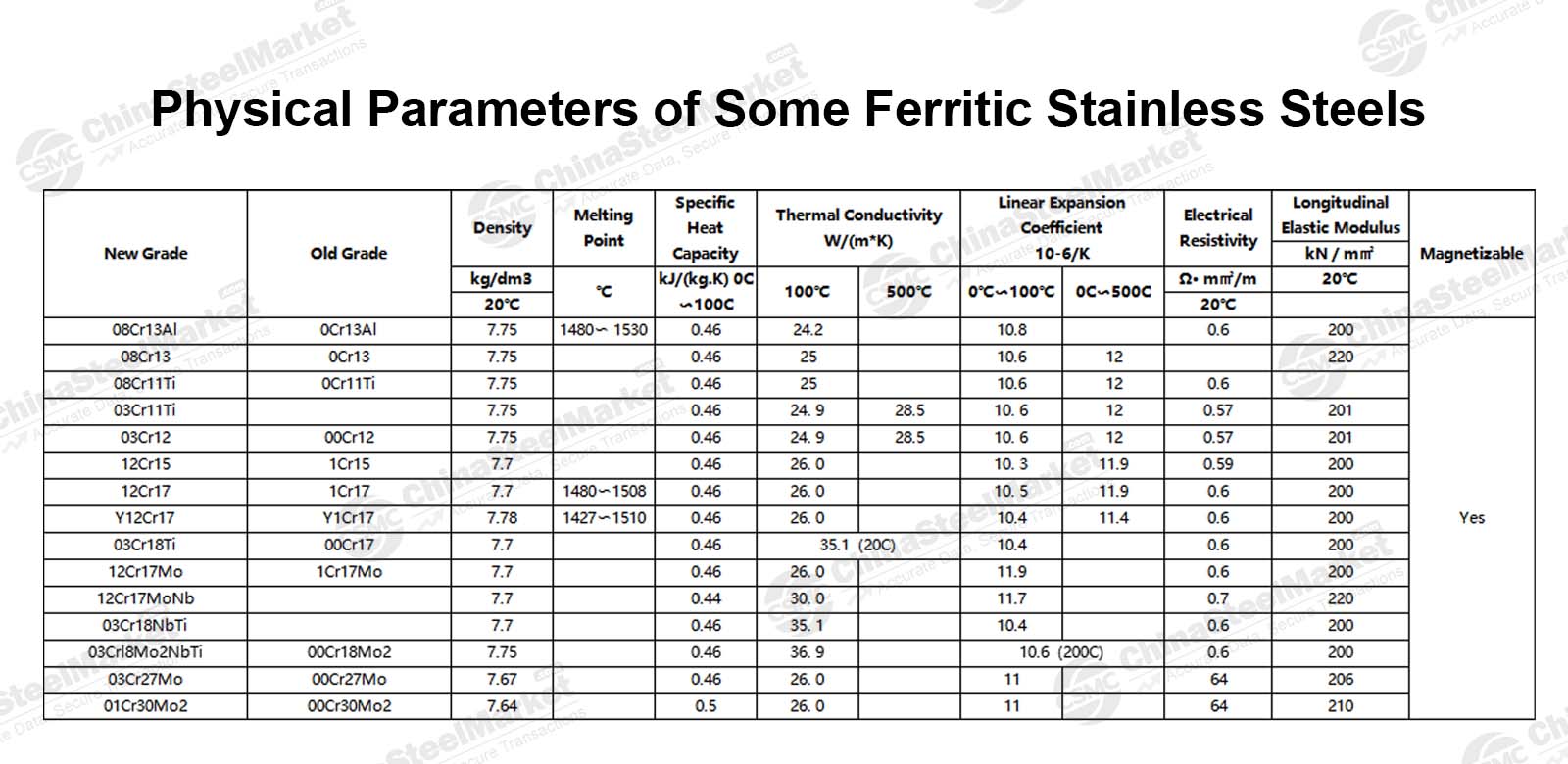

Physical Properties

Ⅲ Martensitic Stainless Steel

Martensitic stainless steel usually contains 11.5%-18% chromium and less than 1.2% carbon, sometimes also containing nickel. It can be strengthened by heat treatment and has moderate corrosion resistance. It is used in knives, surgical tools, wrenches, and turbines.

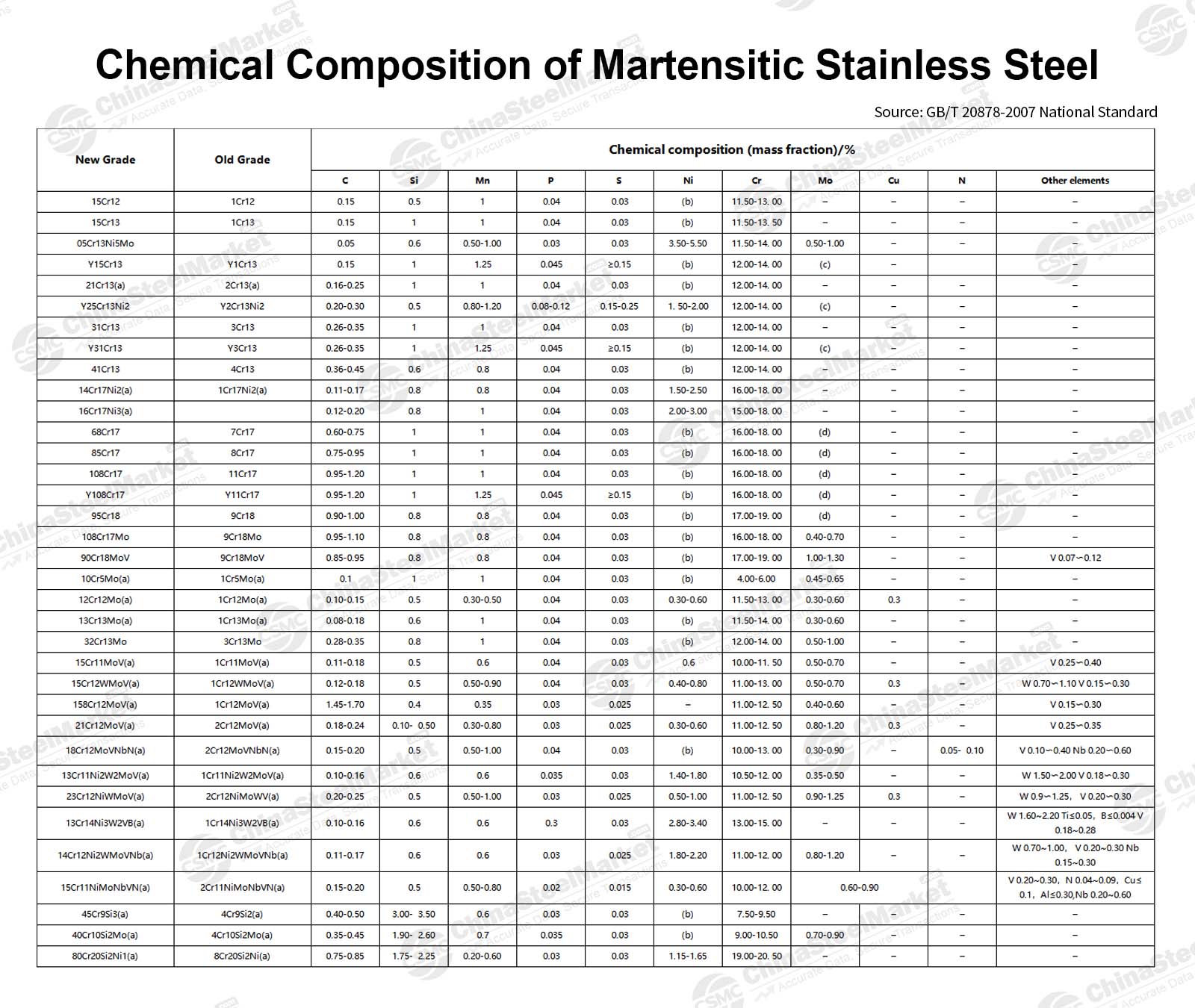

Chemical Composition

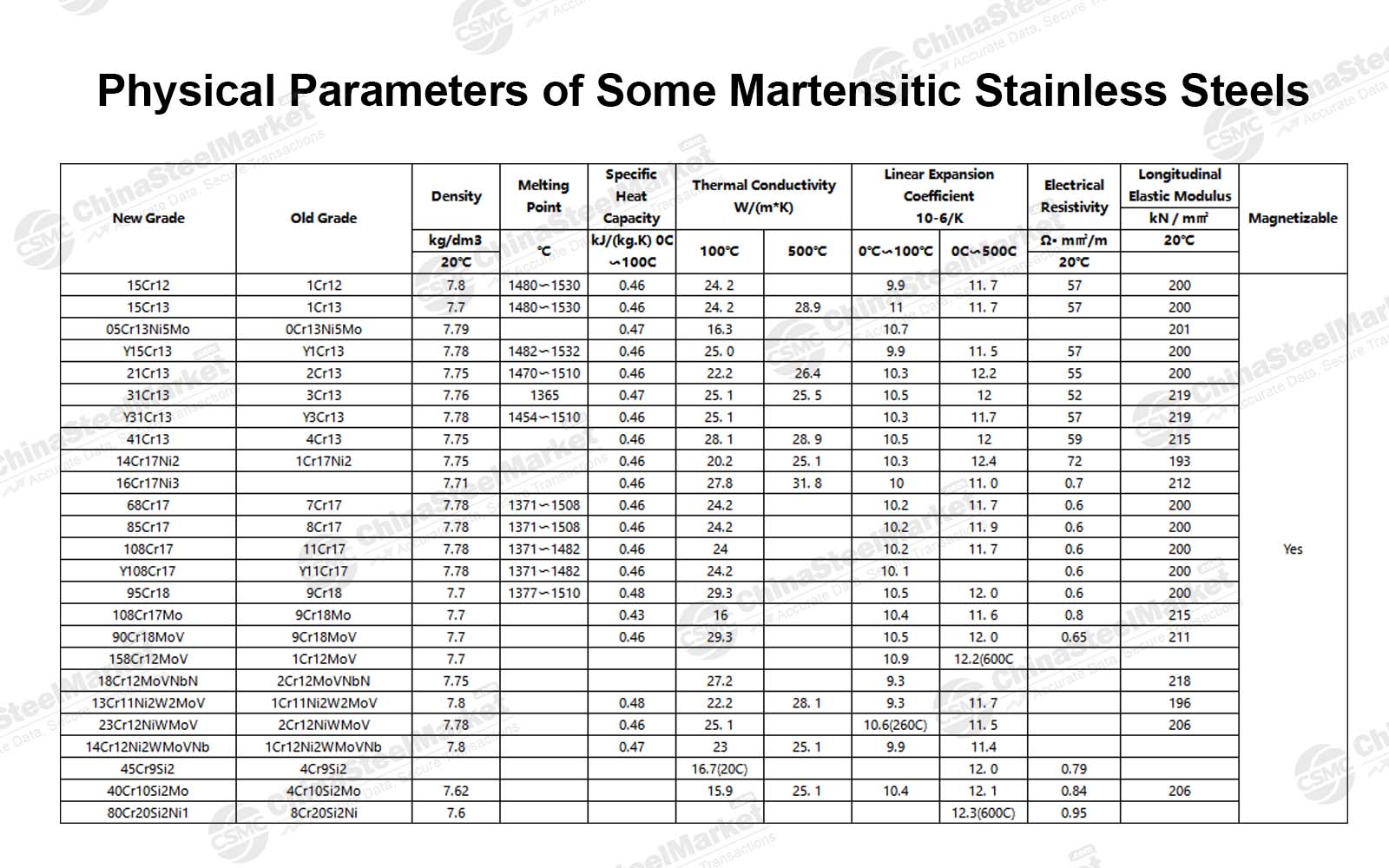

Physical Properties

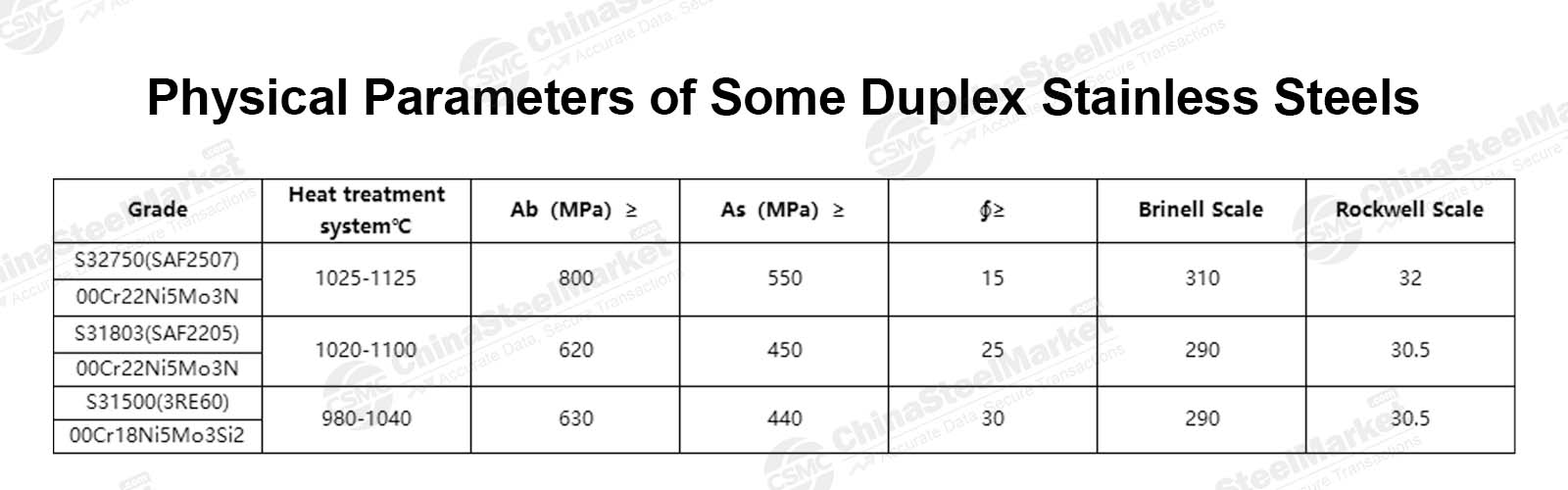

Ⅳ Duplex Stainless Steel

Duplex stainless steels combine the microscopic crystal structures of austenitic and ferritic stainless steels. Duplex stainless steels have approximately twice the yield strength of austenitic stainless steels. Compared to 304 and 316 stainless steel, its mixed crystal structure produces better corrosion resistance against chloride corrosion. Therefore, duplex stainless steel is mostly used in the oil and gas industry.

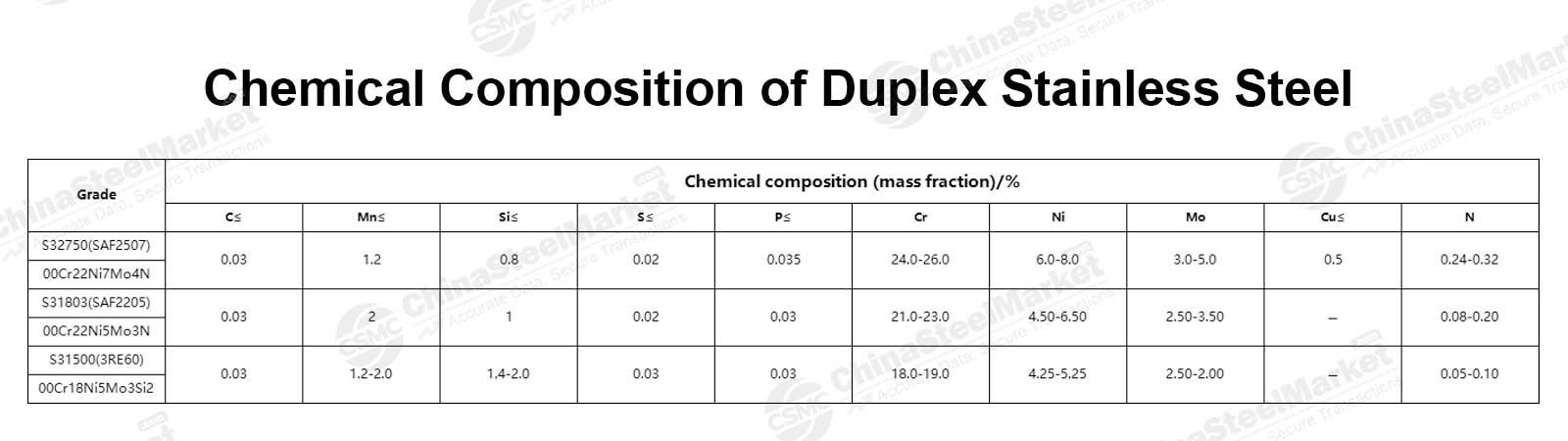

Chemical Composition

Physical Properties

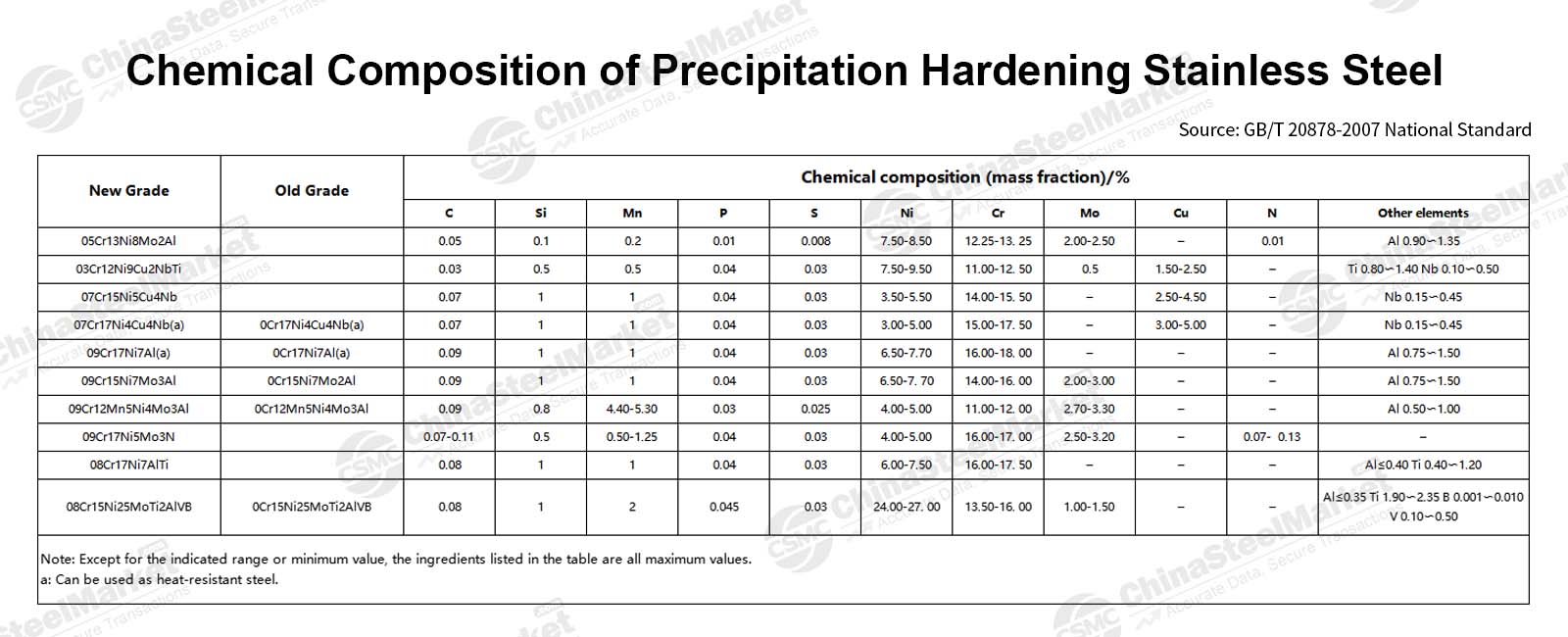

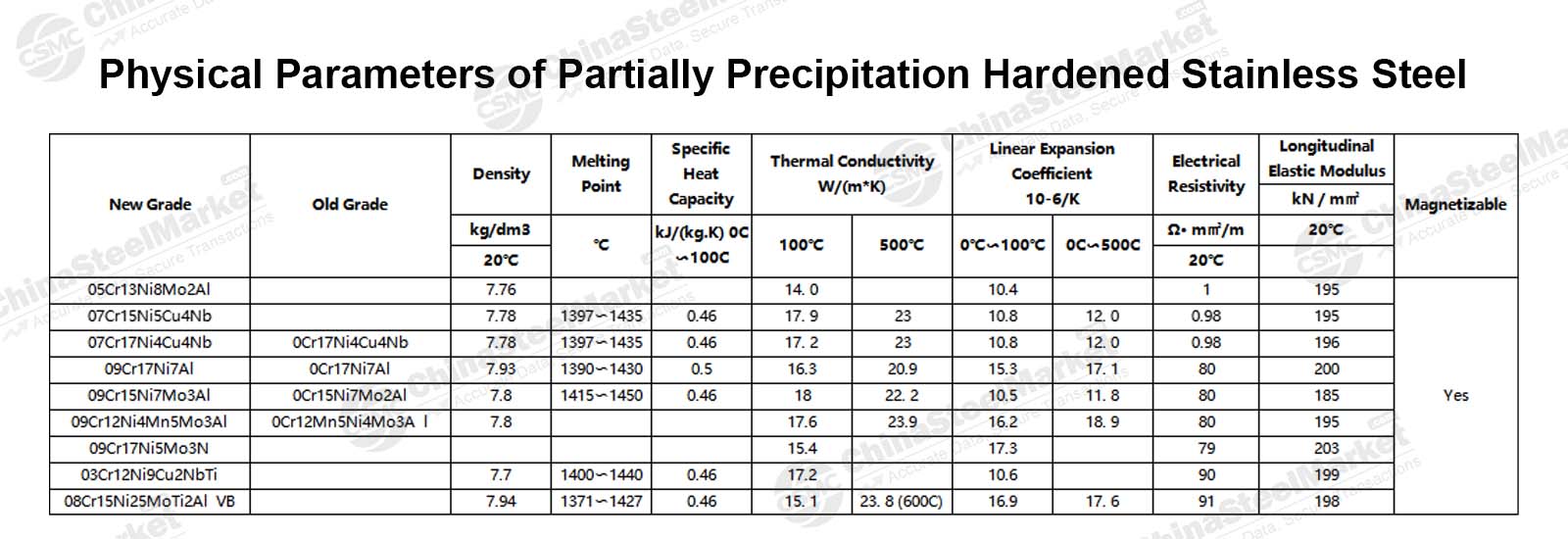

Ⅴ Precipitation Hardening Grade Stainless Steel

Precipitation-hardening stainless steel has a matrix of austenite or martensite structure and can be hardened (strengthened) through precipitation hardening (also called age hardening) treatment.

Chemical Composition

Physical Properties

Stainless steel has many advantages, making it widely used in various fields. One of the main features of stainless steel is its excellent corrosion resistance. It can resist the erosion of most chemicals, including acids, alkalis, salts, etc., allowing it to maintain long-term stability in harsh environments.

Secondly, stainless steel maintains strength and corrosion resistance at high temperatures, making it suitable for high-temperature processes and applications such as boilers, furnaces, engine parts, etc. In addition, stainless steel has excellent mechanical properties, including strength, hardness, ductility, and impact toughness, making it suitable for manufacturing various structures and parts. In addition, stainless steel has the advantages of easy processing, ornamental appearance, sustainability, and other advantages.

Generally speaking, in addition to alloy steels, austenitic stainless steels have excellent corrosion resistance. In less corrosive environments, ferritic stainless steel can be used. In mildly corrosive environments, if the material is required to have high strength or hardness, we can choose martensitic stainless steel and precipitation-hardened stainless steel.

The chemical composition and physical properties of steels mentioned in the article refer to the standard document GB/T 20878-2007.

If you have any corrections, please contact the editor: gianna@chinasteelmarket.com

Editor: Gianna, Hana

Mail: gianna@chinasteelmarket.com

|

|

|

|

|

| Timely Info | Independent | Platform | Multiple guarantees | Self-operated storage |

| About us | Channel | Useful tools |

|---|---|---|

| About China Steel Market | Prices | Steel weight calculation |

| Contact us | Answers | |

| Terms & Conditions | Inventory | |

| Privacy Policy | Help |

Hot search words: