To meet the needs of various industries and enhance the performance level of stainless steel products, stainless steel manufacturers use modern technology in physics, chemistry, and other disciplines to change the physical and chemical properties of the surface of stainless steel products so that they are more suitable for different application environments and functional requirements. We usually refer to this operation applied to stainless steel products as the stainless steel surface treatment process.

The stainless steel surface treatment process plays an important role in the manufacturing of stainless steel products, and it has a significant impact on the appearance, corrosion resistance, mechanical properties, and service life of the product.

In this article, CSMC will focus on six common surface treatment processes. At the same time, CSMC will use pictures and text to illustrate vividly these six surface treatment processes. We hope this will be helpful to our customers.

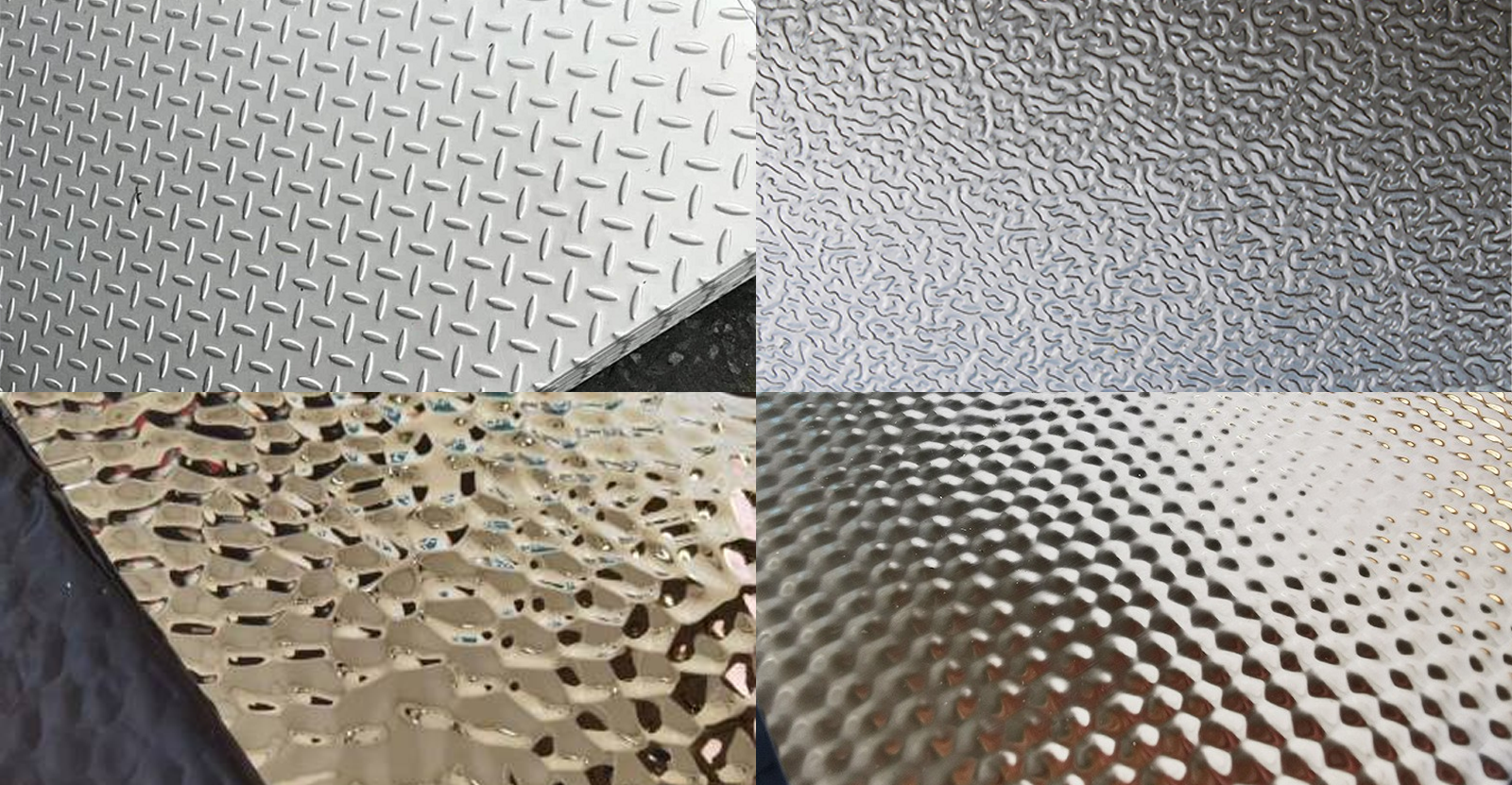

Ⅰ Embossing

A stainless steel embossed plate is embossed on the stainless steel plate by mechanical equipment so that the plate surface appears concave and convex texture, with a three-dimensional visual effect. The advantages of this process are its beautiful appearance, high surface hardness, more wear resistance, ease of cleaning, anti-fingerprint, and so on.

Embossing

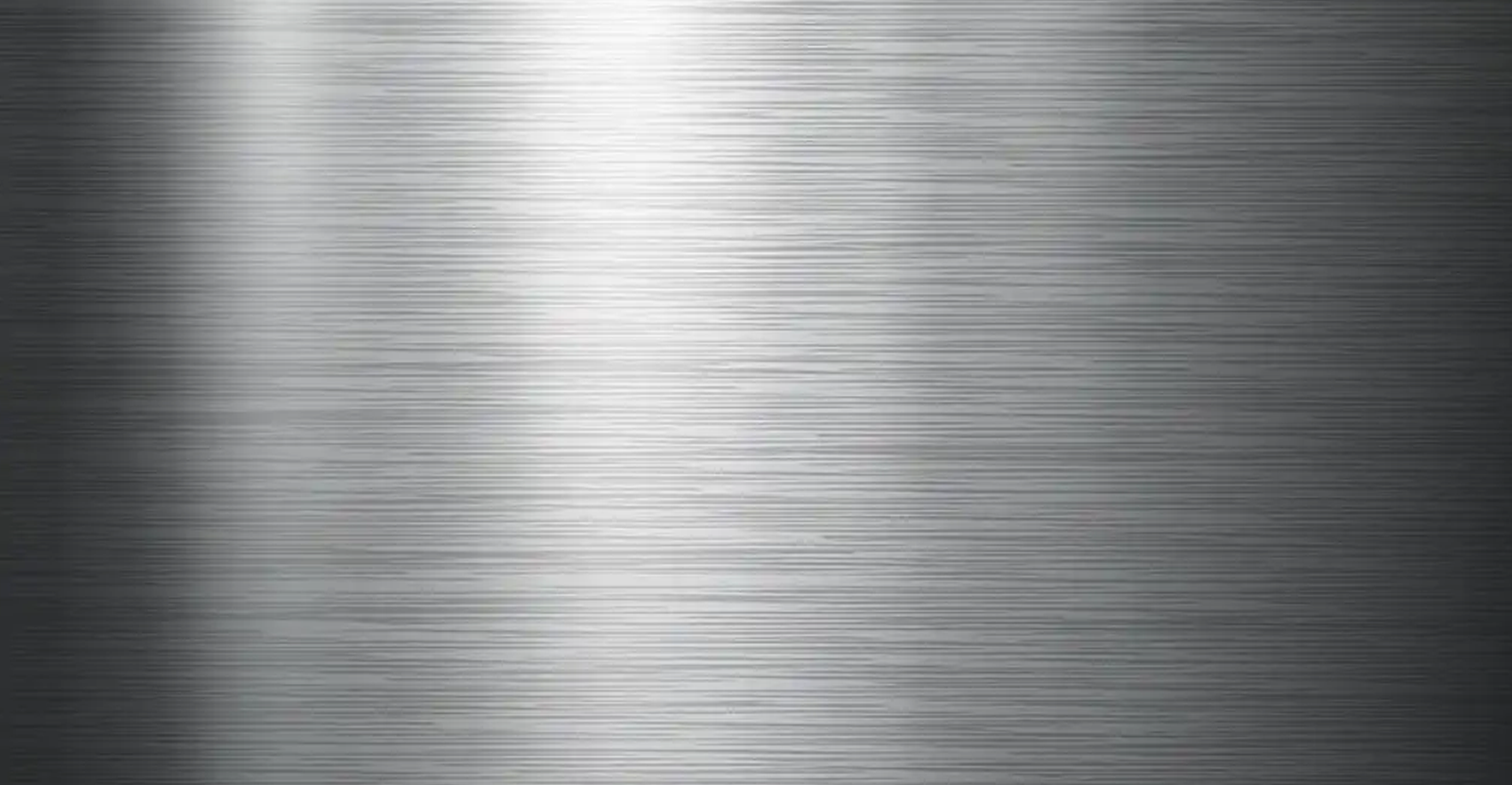

Ⅱ Drawing

Brushed, also known as HL, surface processing treatment is a hairline straight effect, hence the name. The drawing process will lose the thickness of the stainless steel plate to a certain extent, generally ranging from 0.1 to 0.2mm. The effect of the drawing includes drawing, grain (messy grain), ripple, etc.. Colored stainless steel brushed plate is the surface of the substrate in the stainless steel brushed plate through the coloring process to get a variety of colors of the surface.

Drawing

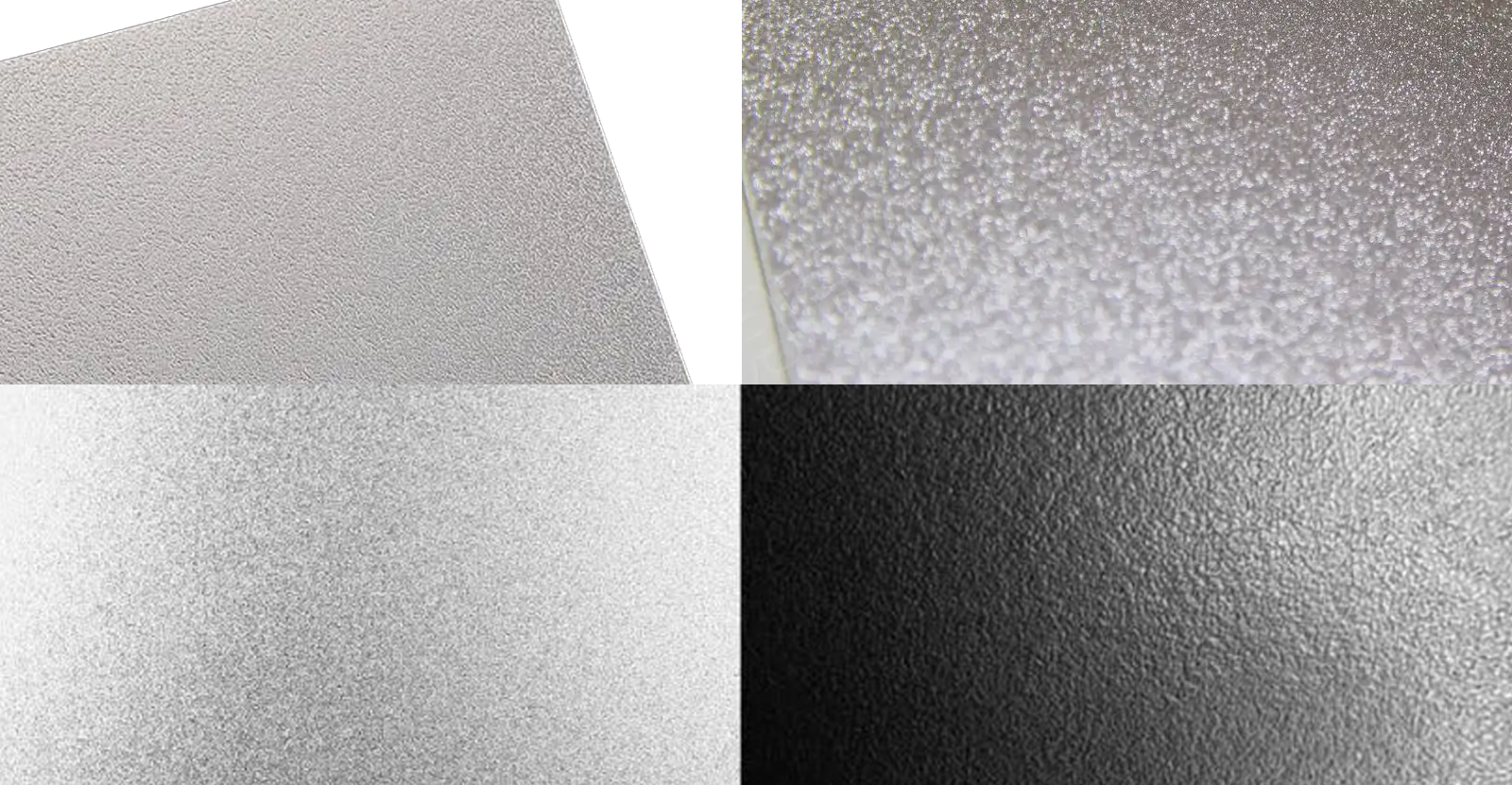

Ⅲ Frosted

Brushing refers to the polished surface obtained by the grinding process on the surface of a steel plate or steel strip using abrasive materials such as abrasive belts and abrasive tips. In terms of process, brushing, snowflake sand, and mirror 8K all belong to a kind of sanding. Sanding can be divided into dry sanding and wet sanding, and wet sanding is divided into water grinding and oil grinding.

Frosted 1

Frosted 2

Ⅳ Mirror

Mirror surface refers to a bright surface effect obtained by rough grinding, medium grinding, and fine grinding using high-quality oilstone, diamond grinding paste, and different grades of sandpaper using polishing and grinding equipment. The mirror surface is an "8K" surface in the stainless steel industry. Common mirror stainless steel is divided into three types: 6K, 8K, and 10K. The higher the level, the brighter the mirror effect.

Mirror

V Sandblasting

Sandblasting refers to the processing of stainless steel plate surfaces by mechanical equipment. The principle of this process is to use compressed air as a driving force to form a high-speed jet beam that will be sprayed at high speed to the surface of the workpiece that needs to be processed so that the plate surface presents a fine bead-like sand surface, forming a unique decorative effect. Sandblasted plate not only retains the excellent mechanical properties and corrosion resistance of stainless steel sandblasted plate but also has a colorful and beautiful color.

Sandblasting

VI Fingerprint Resistance

Stainless steel fingerprint-resistant (also called fingerprint-free, fingerprint-resistant) refers to a composite coating plate obtained after fingerprint-resistant treatment on the surface of stainless steel, and its coating method mainly adopts roller coating.

Fingerprint Resistance

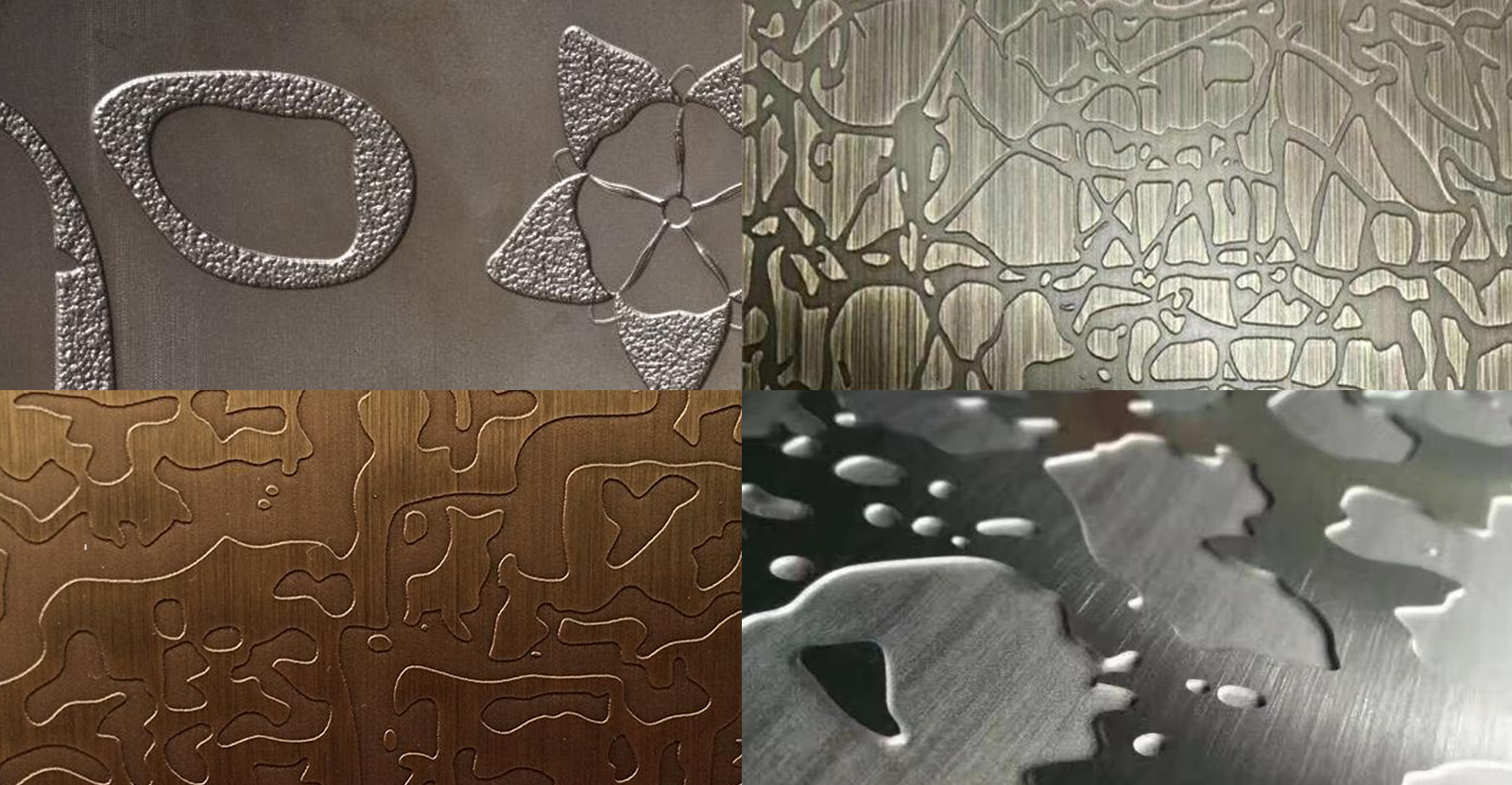

Ⅶ Etching

A stainless steel etching plate is on the object's surface through the chemical method, with acid contact etched off part of the surface to corrode various pattern patterns. The stainless steel etching plate has a three-dimensional sense to achieve a pattern of light and dark & colorful effect.

Etching

Overall, stainless steel surface treatment processes are critical to improving the performance, appearance, and application suitability of stainless steel products. CSMC is committed to providing objective information to help our customers.

If you have any corrections, please contact the editor: gianna@chinasteelmarket.com

Editor: Gianna, Hana

Mail: gianna@chinasteelmarket.com

|

|

|

|

|

| Timely Info | Independent | Platform | Multiple guarantees | Self-operated storage |

| About us | Channel | Useful tools |

|---|---|---|

| About China Steel Market | Prices | Steel weight calculation |

| Contact us | Answers | |

| Terms & Conditions | Inventory | |

| Privacy Policy | Help |

Hot search words: