Galvanized steel sheet & plate and galvalume steel sheet & plate are two common anti-corrosion steel plates widely used in construction, automobiles, home appliances, and other fields. The two products have similarities and differences.

In recent years, the market supply and demand of galvanized steel sheet & plate and galvalume steel sheet & plate have been increasing due to the development of related industries. Based on the current situation, CSMC publishes this article to introduce galvanized steel sheet & plate and galvalume steel sheet & plate, hoping to help customers.

Ⅰ Galvanized Steel Sheet

Galvanized steel sheet is a welded steel sheet with a hot-dip or electroplated zinc layer on the surface. It is widely used in construction, home appliances, vehicles and ships, container manufacturing, and electromechanical industries.

The zinc layer of the galvanized sheet gives it good corrosion resistance and a long service life. In addition, the appearance of the galvanized sheet is beautiful.

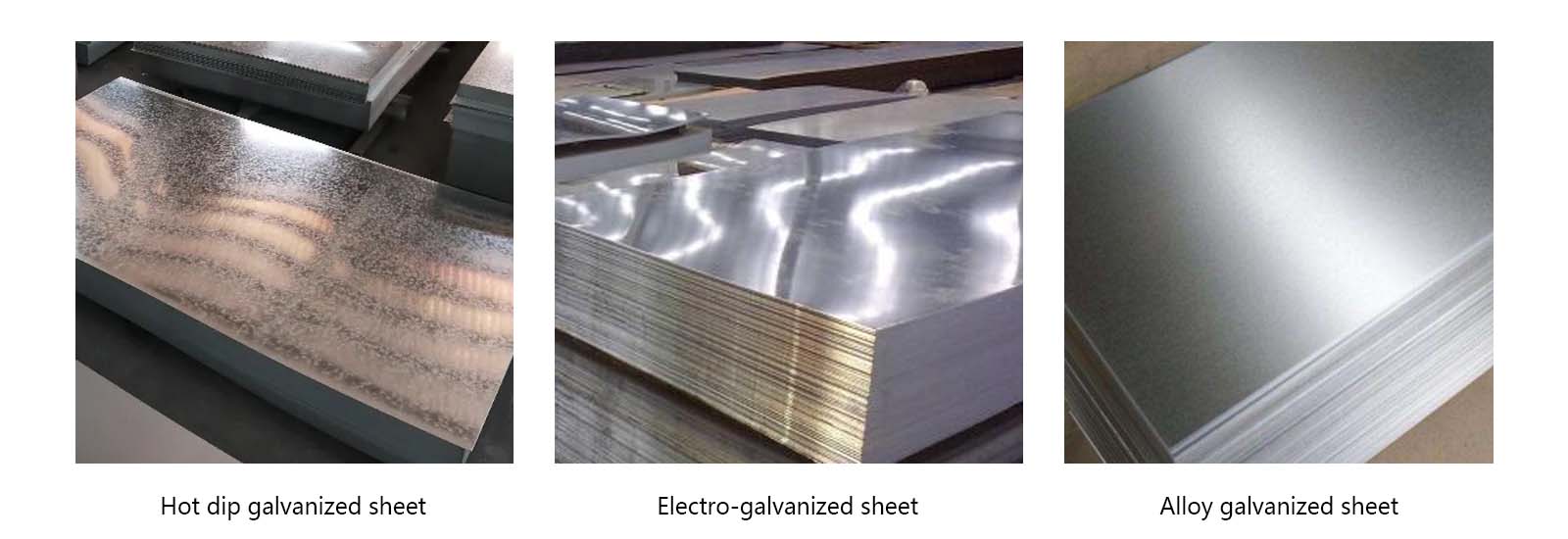

According to the different galvanizing processes, galvanized sheets are mainly divided into hot-dip galvanized sheets, electro-galvanized sheets, and alloy galvanized sheets. Hot-dip galvanized sheet refers to a steel sheet obtained by immersing the steel sheet in molten zinc liquid and coating it with a layer of zinc on its surface. The coating formed by this method is uniform and has strong adhesion.

Electro-galvanized sheet is a galvanized sheet in which a zinc layer is deposited on the surface of the steel sheet through an electrolytic reaction. The coating thickness of the electro-galvanized sheet is thin, but the surface is smooth.

Alloy galvanized sheet is a galvanized steel sheet formed by heating the steel sheet and zinc liquid to a certain temperature to form an alloy coating of zinc and iron. This method improves corrosion resistance and wear resistance.

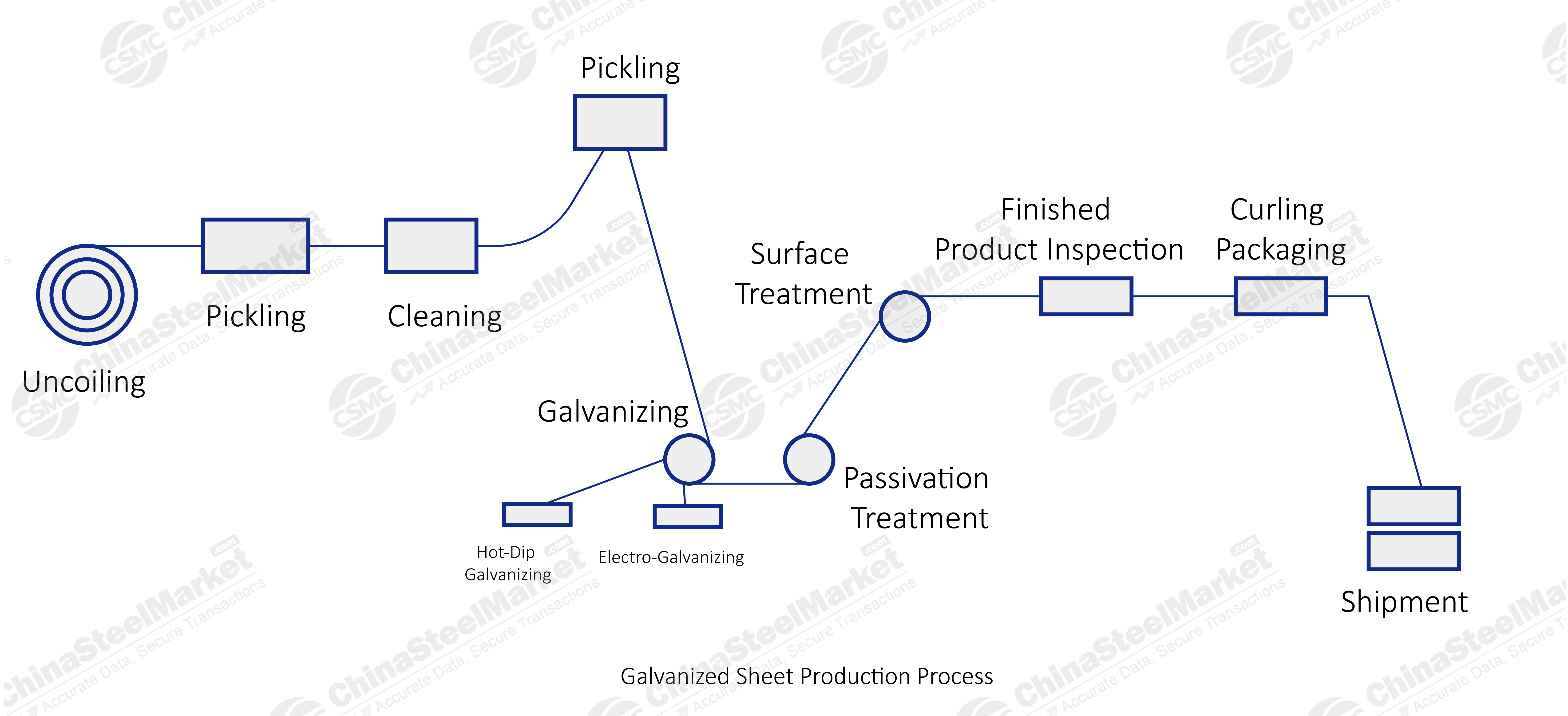

Although there are many types of galvanized sheets, the production processes of several galvanized sheets are still similar.

1. Select a suitable steel coil as the substrate. Then unwind the steel coil to provide the steel strip required for continuous operation. Weld the tail of the front strip with the head of the rear strip to ensure the continuous production of the unit.

2. Clean the surface of the strip to remove rolling oil and iron powder to obtain good coating adhesion and surface quality. Generally includes spraying, brushing, electrolytic cleaning, re-brushing, re-spraying, squeezing, and hot air drying equipment. The cleaning section is more important for hot-dip galvanizing and is an important step to obtain good strip surface quality.

3. Heat the steel coil to an appropriate temperature for annealing to improve its mechanical properties and surface state.

4. Galvanize the steel strip. Different galvanized sheets have different galvanizing operations.

5. Finish the galvanized steel strip. These operations include controlling the coating thickness on the surface of the strip, flattening and stretching the steel strip, and alloying treatment.

6. Passivate or perform other chemical surface treatment on the strip. Generally, it includes spray drying and roller coating drying.

7. Inspect the product effect. Perform operations such as oiling, cutting, and packaging on qualified products.

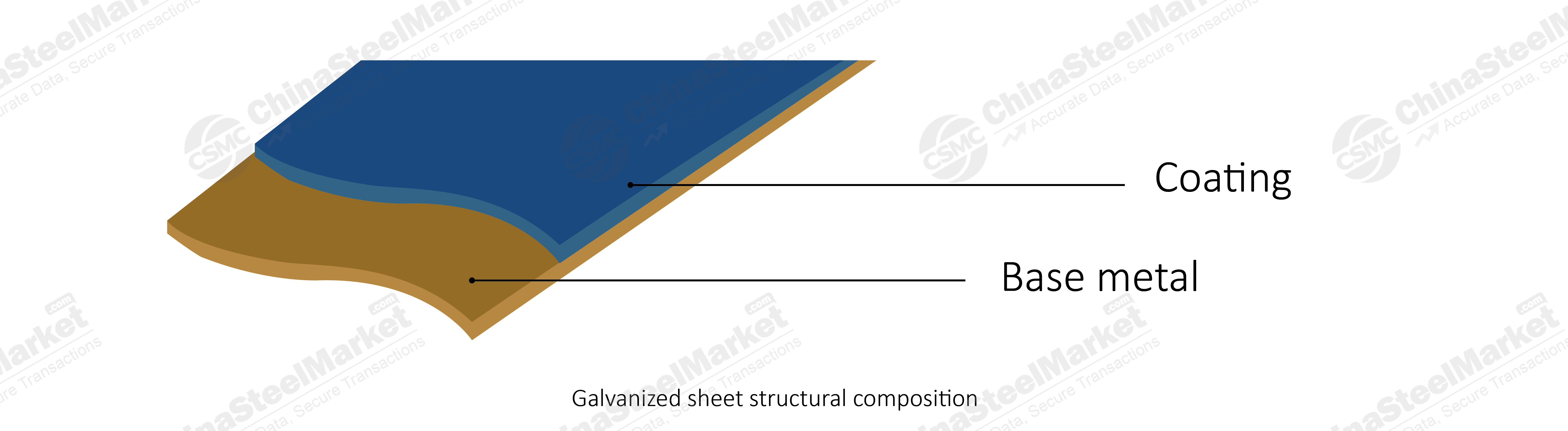

From the production process, the structure of galvanized sheet has two parts. The core of galvanized sheet is steel substrate, which is usually cold-rolled steel or hot-rolled steel. The other part is to coat the surface of the steel substrate with a layer of pure zinc or zinc alloy. The zinc coating is formed by hot-dip galvanizing or electro-galvanizing.

Ⅱ Galvalume Steel Sheet & Plate

Galvalume steel sheet is an A1-Zn alloy coated steel sheet obtained by hot-dip plating based on cold rolled hardened steel sheets of various strength and thickness specifications. It combines the excellent properties of aluminum and zinc to provide excellent corrosion resistance and heat reflection. The coating composition consists of 55% A1, 43.4% zn, and 1.6% Si by weight. The special coating structure provides excellent corrosion and heat resistance and long service life. The coating has good adhesion to the paint film and has good processing performance. The surface of aluminized steel plate has good reflective properties. At temperatures below 500'C, the surface of galvalume steel sheet has a light reflectivity of about 80%; the reflectivity under infrared light can reach 95%.

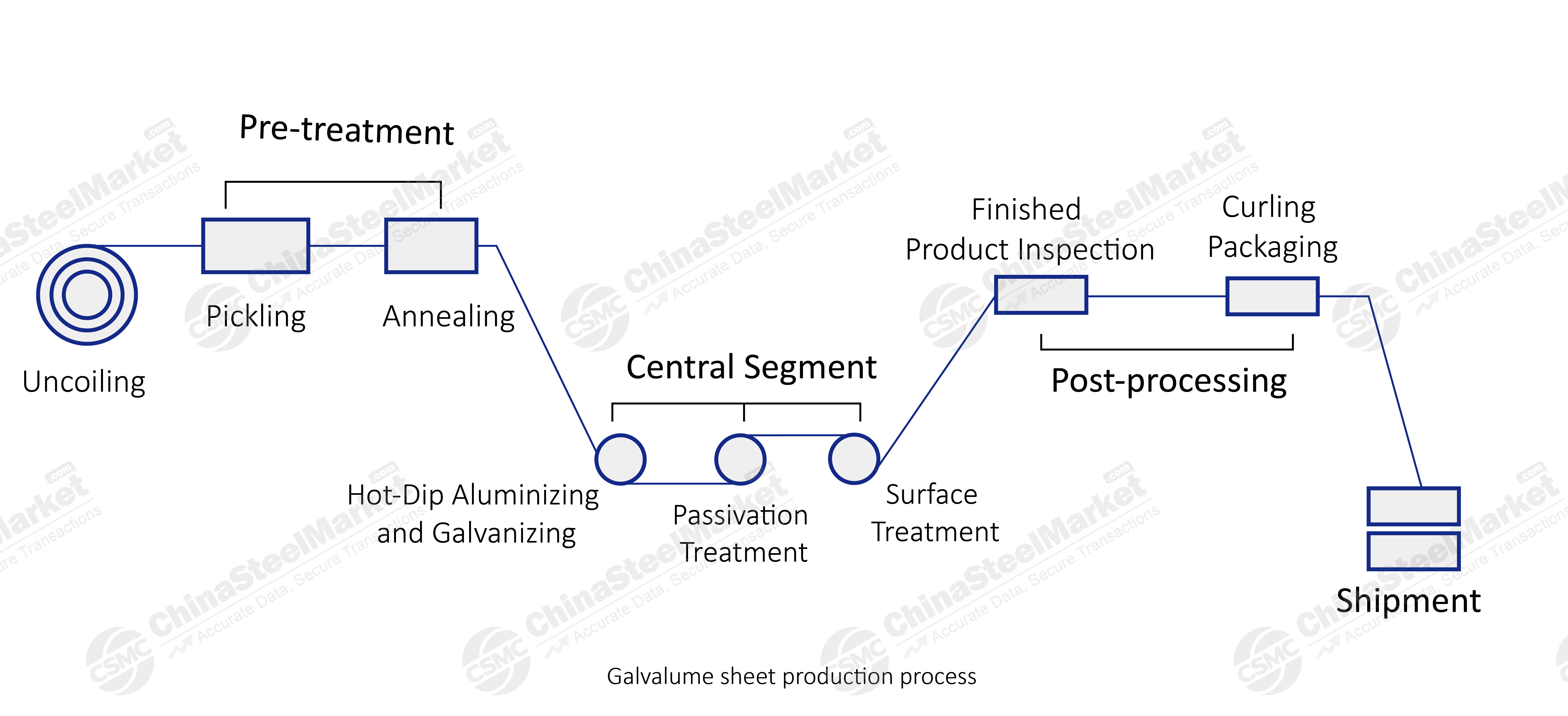

The production process of aluminized zinc sheet is similar to that of galvanized sheet.

1. The prepared steel coil is cleaned and degreased to remove the oxidized skin and impurities on the surface of the steel strip. The steel coil is heated to the appropriate temperature for annealing to improve its mechanical properties and surface condition.

2. The steel plate is put into molten aluminum-zinc alloy liquid to form an aluminum-zinc alloy coating. Then the strip goes into air cooling and then into a water quenching tank for cooling.

3. Apply surface treatment to the aluminum-zinc plated sheet, such as oiling and anti-fingerprint treatment.

4. Inspection of finished products.

Galvalume steel sheet is mainly composed of two parts. One is Steel Substrate, which is usually cold-rolled steel. The other part is aluminum-zinc alloy coating, which typically contains 55% aluminum, 43.4% zinc and 1.6% silicon.

From the manufacturing process, the difference between galvanized sheet and galvalume steel sheet lies in the difference in coating. A layer of zinc material is evenly distributed on the surface of the galvanized sheet, which plays the role of anodic protection for the parent material. In other words, the alternative corrosion of the zinc material protects the parent material. Only when the zinc is completely corroded can the parent material inside be damaged. The surface coating of the galvanized sheet is composed of 55% aluminum, 43.5% zinc, and a small amount of other elements. Under the microscopic level, the surface of the galvanized coating is a honeycomb structure, and the "honeycomb" composed of aluminum contains zinc. Due to the reduction of zinc content and the fact that the zinc material is wrapped by aluminum and is not easy to electrolyze, the role of anodic protection is greatly reduced. Therefore, the galvanized sheet should be cut as little as possible. Once cut, anti-rust paint or zinc-rich paint should be used to protect the edges. Due to the presence of aluminum, the corrosion resistance and heat resistance of the galvanized sheet are better than those of the galvanized sheet. In addition, the thermal reflectivity of the galvalume steel sheet is twice that of the galvanized steel sheet.

In addition to the above, the surface zinc spangles of galvanized sheet and galvalume steel sheet are also an important content. Zinc spangles refer to the appearance of the grains formed after the hot-dip galvanized sheet is pulled out of the zinc pot and the zinc layer cools and solidifies. The appearance of zinc spangles usually presents a crystal pattern with a star shape, a leaf shape, or a snowflake shape.

The size, brightness, and surface morphology of zinc spangles are mainly related to the composition of the zinc layer and the cooling method. There are three types of zinc spangles, namely large zinc spangles, small zinc spangles, and no zinc spangles. Large spangles refer to those with a diameter greater than 3mm that can be distinguished by the naked eye. Some people also call them normal zinc spangles or natural zinc spangles. The internationally recognized optimal size is 8~12mm. Zinc spangles with a diameter of 1~2mm are called small zinc spangles. Zinc spangles are small and evenly distributed and are more delicate and smooth than ordinary spangles. Zinc spangles cannot be seen on the plate surface with the naked eye, which is called no zinc spangles, also known as zero zinc spangles. It is achieved by controlling the chemical composition of the zinc liquid.

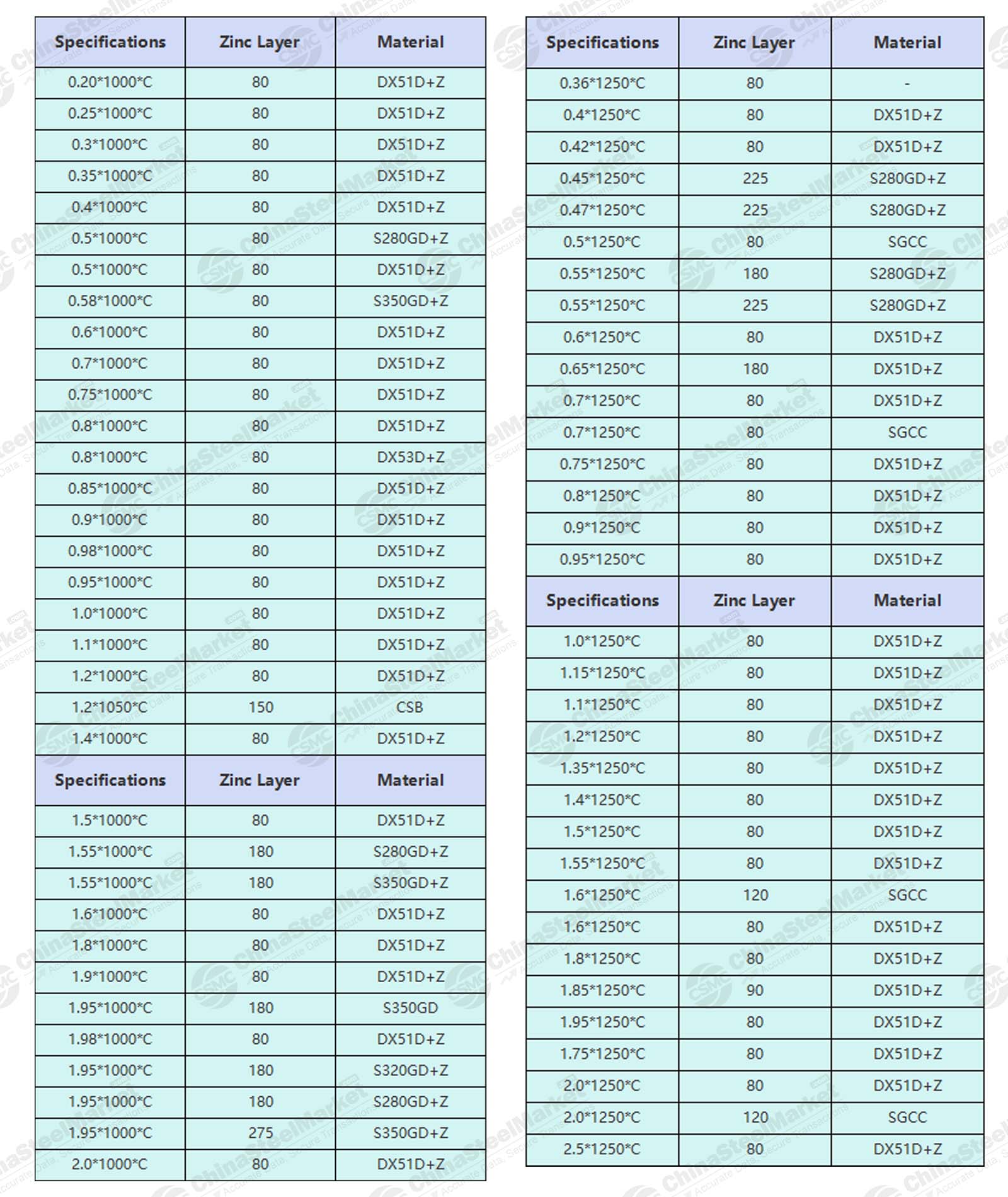

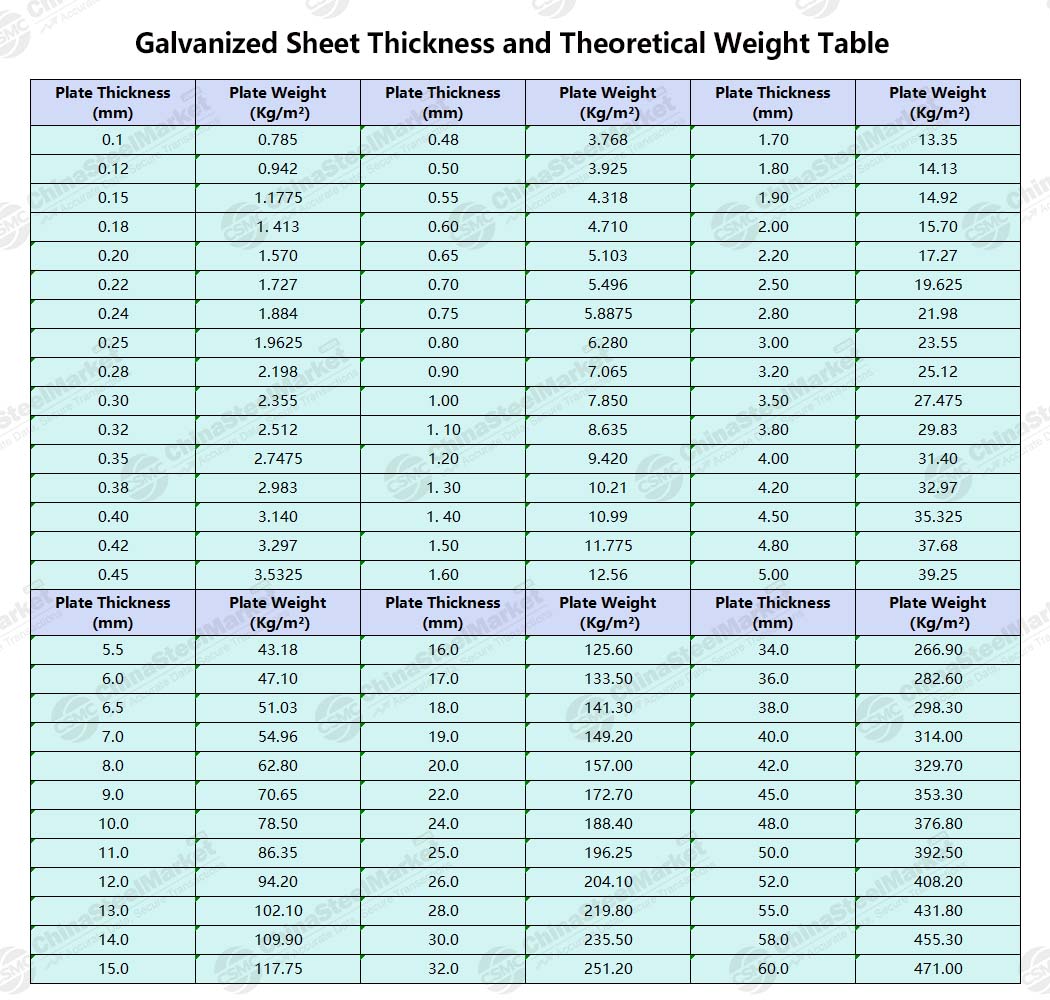

There are many large steel production enterprises in China. These steel enterprises continue to improve production technology, breakthrough production limits, and develop many new products. In addition, the types of deep-processing products of galvalume steel sheet & plate and galvanized steel sheets are also increasing. With the development of the coating and plating product industry, the specifications of galvalume steel sheet & plate and galvanized steel sheets are becoming more and more complete, including length, width, height, thickness, and zinc layer thickness. Different steel manufacturers have different advantages and specifications.

Galvanized steel sheet and galvalume steel sheet & plate have excellent anti-corrosion performance and long service life. In particular, galvanized steel sheet has excellent heat reflection performance. This makes them widely used in construction, automobiles, home appliances, and other fields. Therefore, the market demand for galvanized steel sheet and galvalume steel sheet & plate is increasing.

Galvanized steel sheet and galvalume steel sheet & plate have excellent anti-corrosion performance and long service life. In particular, galvanized steel sheet has excellent heat reflection performance. This makes them widely used in construction, automobiles, home appliances, and other fields. Therefore, the domestic and international market demand for galvanized steel sheet and galvalume steel sheet & plate is increasing.

China has very obvious advantages in the production and export of galvanized sheet and galvalume steel sheet & plate. First of all, China has abundant raw material resources, a strong steel manufacturing industry, and a developed transportation environment. This makes the cost of galvanized sheet and galvalume steel sheet & plate in China lower, and then China's export price has a certain competitive advantage. Secondly, China has several large steel manufacturing enterprises. These steel companies are constantly upgrading their production technology, breaking through production limits, and developing many new products. The sizes of galvanized and galvalume steel sheet & plate are increasing, such as 0.15mm, and 2.5mm, and the types of deep-processed products of galvanized and galvalume steel sheet & plate are also increasing. This has led to a diverse selection of galvanized and galvalume steel sheet & plate and further processed products in China. This explains China's relatively high export volume.

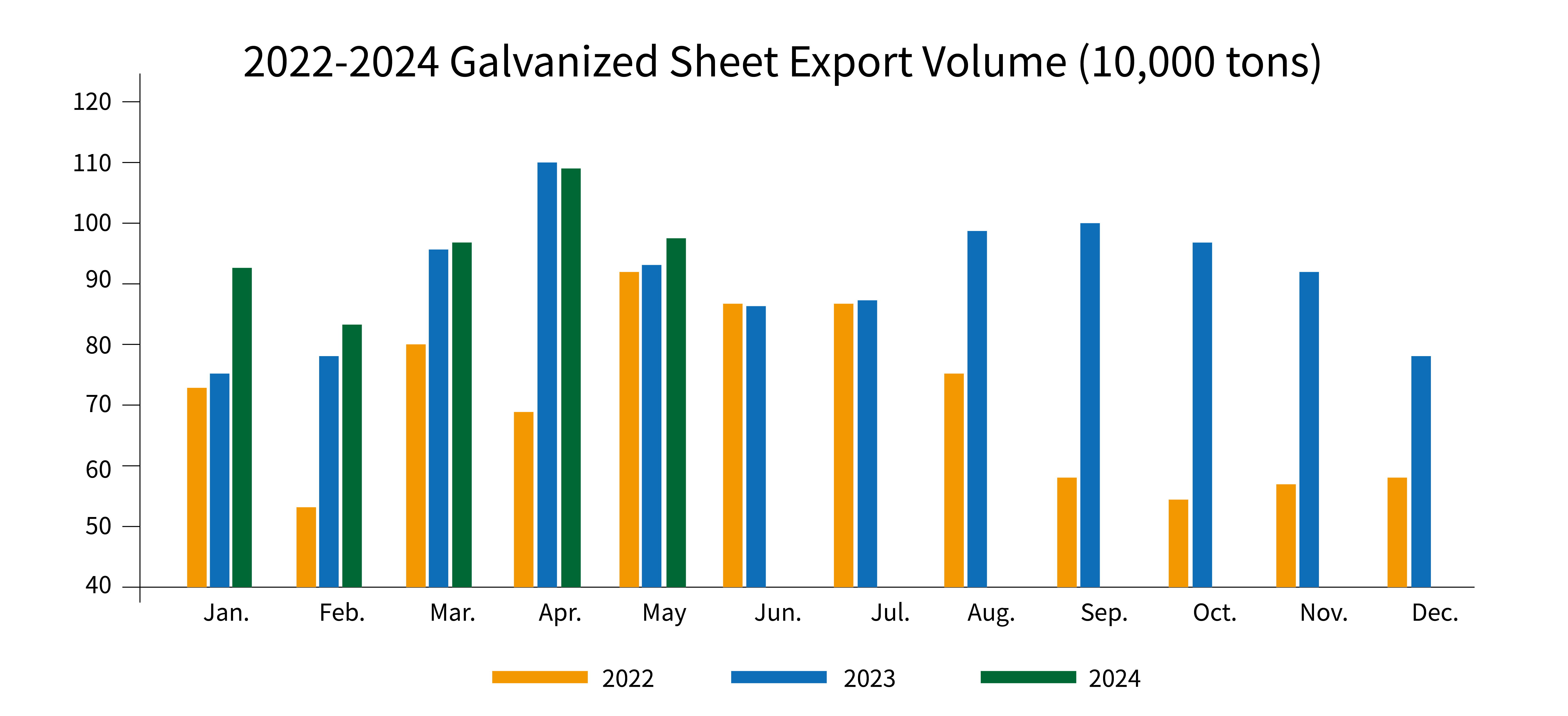

Taking the export volume of galvanized sheets in China as an example, we can see that the export volume of galvanized sheet shows an upward trend, in which the export volume increases rapidly in the first half of 2023.

Due to the downturn in the real estate industry, the export volume declined in the second half of 2023. At the same time, galvanized sheet and galvalume steel sheet & plate industry has begun to develop in the direction of deep processing. Exports of further processed products based on galvanized and galvalume steel sheet & plate are increasing. Therefore, the production volume and export volume of galvanized sheet and galvalume steel sheet & plate will still maintain the growth trend, only the magnitude will be small.

Under the influence of various international and domestic factors, the import and export of galvanized steel sheets and galvalume steel sheets & plates have shown certain fluctuations. The development of the industry will also face certain challenges and opportunities in the future. CSMC will also continue to pay attention to the development of the steel industry and actively provide customers with useful information.

We sincerely hope that the information we provide can make more beneficial value. In addition, we sincerely invite you to leave valuable comments and advice on our website. We will follow your comments and advice at any time on our website.

CSMC-Empowering small and medium-scale steel purchasing.

Editor: Gianna Hana

Mail: gianna@chinasteelmarket.com

|

|

|

|

|

| Timely Info | Independent | Platform | Multiple guarantees | Self-operated storage |

| About us | Channel | Useful tools |

|---|---|---|

| About China Steel Market | Prices | Steel Weight Calculation |

| Contact Us | Answers | Why Choose Us |

| Terms & Conditions | Inventory | |

| Privacy Policy | Help |

Hot search words: